This subassembly automatically applies various subassemblies, such as generic links, widening, ditching, or daylighting subassemblies, to an assembly based on whether a cut or fill condition exists.

The ConditionalCutOrFill subassembly is a special type of subassembly that is referred to as a conditional subassembly. Conditional subassemblies automatically add specified subassemblies to an assembly when certain conditions, which you specify, exist.

For example, when an assembly contains a ConditionalCutOrFill subassembly, Autodesk Civil 3D analyzes the station, offset, and elevation position of the subassembly to determine whether it is in cut or fill condition. Depending on how you set the ConditionalCutOrFill subassembly parameters, different types of subsequent subassemblies are automatically applied (added) to the assembly based on whether the subassembly is in cut or fill.

To learn more about how to use the ConditionalCutOrFill subassembly, see the tutorial.

The following illustration shows a corridor assembly section comprised of:

- a left and a right side lane

- four ConditionalCutOrFill subassemblies (two on the left side and two on the righ side)

- The top left side ConditionalCutOrFill subassembly is configured to automatically add a Bench subassembly when Autodesk Civil 3D detects that the assembly is in a cut condition.

- The bottom left side ConditionalCutOrFill subassembly is configured to automatically add Shoulder and Grade subassemblies on the left side when it detects that the subassembly is in a fill condition.

- Similarly, the top right side ConditionalCutOrFill subassembly is configured to add a Ditch subassembly when it detects a cut condition, while the bottom right side ConditionalCutOrFill subassembly adds Shoulder and Grade subassemblies when it detects a fill condition.

You can add one or multiple ConditionalCutOrFill subassemblies to an assembly, thereby creating simple or complex conditional behaviors in assemblies. For example, in the previous example, you can also add a ConditionalCutOrFill subassembly that automatically daylights at a given slope when it detects that it is in fill condition greater than 3 meters, or some other specified value. Similarly, you can add a ConditionalCutOrFill subassembly that automatically applies widening when it detects a fill condition of greater than a specified value.

When you create an assembly using ConditionalCutOrFill subassemblies, the assembly construction displayed in the Construction tab of the Assembly Properties dialog box indicates the order in which the subassemblies are processed.

It is important to note the following when using the ConditionalCutOrFill subassembly:

- Autodesk Civil 3D analyzes the station, offset, and elevation position of the subassembly, relative to the target surface, to determine whether the subassembly is in cut or fill condition.

- When an assembly containing ConditionalCutOrFill subassemblies is applied to a corridor model, only specific portions of the assembly will be applied at any given station.

- Since the ConditionalCutOrFill subassembly uses targets, you must set targets on any ConditionalCutOrFill subassemblies before modeling (generating) the corridor. For more information, see To Specify Corridor Targets.

- Unlike most other subassemblies, the ConditionalCutOrFill subassembly does not create any points, links, or shapes in modeling mode.

Multiple ConditionalCutOrFill Subassemblies

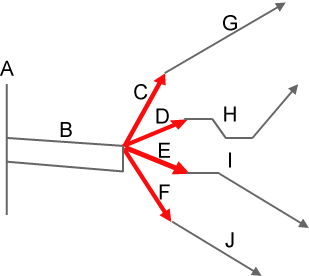

Multiple ConditionalCutOrFill subassemblies may be attached to a common point on an assembly. This includes multiple cut and or multiple fill ConditionalCutOrFill subassemblies, as shown in the following illustration.

This illustration shows only the right side of the assembly. The following table describes the components included on this side of the assembly.

| Component | Description |

|---|---|

| A | Assembly baseline |

| B | Right side Lane subassembly |

| C | ConditionalCutOrFill subassembly, with Type parameter set to Cut. If the condition is in cut, and the cut condition is between the minimum/maximum distance values specified for subassembly (C), then a specified type of subassembly (G) is applied. |

| D | ConditionalCutOrFill subassembly, with Type parameter set to Cut. If the condition is in cut, and the cut condition is between the minimum/maximum distance values specified for subassembly (D), then a Ditch subassembly (H) is applied. |

| E | ConditionalCutOrFill subassembly, with Type parameter set to Fill. If the condition is in fill, and the fill condition is between the minimum/maximum distance values specified for subassembly (E), then a specified type of subassembly (I) is applied. |

| F | ConditionalCutOrFill subassembly, with Type parameter set to Fill. If the condition is in fill, and the fill condition is between the minimum/maximum distance values specified for subassembly (F), then a specified type of subassembly (J) is applied. |

| G | A specified type of subassembly that is applied in cut conditions that are between the minimum/maximum distance values specified for subassembly (C). |

| H | A specified type of subassembly that is applied in cut conditions that are between the minimum/maximum distance values specified for subassembly (D). |

| I | A specified type of subassembly that is applied in fill conditions that are between the minimum/maximum distance values specified for subassembly (E). |

| J | A specified type of subassembly that is applied in fill conditions that are between the minimum/maximum distance values specified for subassembly (E). |

You control the cut or fill limit heights using the Minimum Distance and Maximum Distance input parameters. The Layout Width and Layout Grade input parameters let you control the position of the graphics displayed by this subassembly when it is drawn in layout mode.

There is no limit to the number of ConditionalCutOrFill subassemblies that can be added to an assembly.

Attachment

This subassembly can be attached to any subassembly or assembly attachment point. Subsequent subassemblies can be attached to the end point of the ConditionalCutOrFill subassembly.

Input Parameters

Note: All dimensions are in meters or feet unless otherwise noted. All slopes are in run-over-rise form (for example, 4 : 1) unless indicated as a percent slope with a “%” sign.

| Parameter | Description | Type | Default |

|---|---|---|---|

| Side | Specifies which side of the assembly or corridor the subassembly is inserted towards. | Left/Right | Right |

| Layout Width | Specifies the length of the line that is drawn to represent this subassembly in layout mode. This parameter, in combination with the Layout Grade parameter, allows you to position the ConditionalCutOrFill subassembly and subassemblies that are attached to it, but does not display or have any effect in the corridor model. | Numeric, positive |

3.6 m 12.0 ft |

| Layout Grade | Specifies the grade of the line that is drawn to represent this subassembly in layout mode. This parameter, in combination with the Layout Width parameter, allows you to position the ConditionalCutOrFill subassembly and subassemblies that are attached to it, but does not display or have any effect in the corridor model. | Numeric, positive or negative |

1:1 (cut) -1:1 (fill) |

| Type | Specifies the type of condition this subassembly uses to compare itself against the target. | Cut / Fill | Cut |

| Minimum Distance | Specifies the minimum cut depth or minimum fill height that is required in order to continue processing subassemblies connected to this ConditionalCutOrFill subassembly. | Numeric, positive or negative |

0.0 m 0.0 ft |

| Maximum Distance | Specifies the maximum cut depth or maximum fill height that is required in order to continue processing subassemblies connected to this ConditionalCutOrFill subassembly. | Numeric, positive |

9999. ft 9999. m |

Target Parameters

This section lists the parameters in this subassembly that can be mapped to one or more target objects, such as a surface, alignment, or profile object in a drawing. For more information, see To Specify Corridor Targets.

| Parameter | Description | Status |

|---|---|---|

| Surface | Surface that is used to determine whether the current station, offset, and elevation is in a cut or a fill condition. The station, offset, and elevation that is used is from the ConditionalCutOrFill subassembly attachment point. | Required |

Output Parameters

None.

Behavior

See description.

Layout Mode Operation

In layout mode, this subassembly draws a line using the Layout Width and Layout Grade input parameter values. This line represents the location in the assembly where the ConditionalCutOrFill subassembly is applied.

Point, Link, and Shape Codes

Unlike most other subassemblies, the ConditionalCutOrFill subassembly does not create any points, links, or shapes in modeling mode.

Coding Diagram

The following coding diagram shows the points and links that are created in layout mode. No point, link, or shape codes are created for this subassembly in modeling mode.