This subassembly adds an overlay layer on an existing uncrowned roadway or ramp, with either a leveling and milling layer added as required.

Attachment

The attachment point is the edge of overlay on finish grade at the inside trim point.

Input Parameters

Note: All dimensions are in meters or feet unless otherwise noted. All slopes are in run-over-rise form (for example, 4 : 1) unless indicated as a percent slope with a “%” sign.

|

Parameter |

Description |

Type |

Default |

|---|---|---|---|

|

Inside Sample Point Offset |

Offset of the inside sample point. The sample points are used to calculate the slope of the existing roadway. Specifying a positive value for the this parameter inserts this subassembly on the right side of a corridor, or controlling baseline. A negative value inserts it on the left side. For more information, see "Inserting Subassemblies on Right and Left Sides of a Corridor" in the Corridors chapter of the Autodesk Civil 3D User's Guide Help. |

Numeric |

0.0 |

|

Outside Sample Point Offset |

Offset of the outside sample point. Specifying a positive value for the this parameter inserts this subassembly on the right side of a corridor, or controlling baseline. A negative value inserts it on the left side. For more information, see "Inserting Subassemblies on Right and Left Sides of a Corridor" in the Corridors chapter of the Autodesk Civil 3D User's Guide Help. |

Numeric |

0.0 |

|

Inside Trim Point |

Offset of the inside trim point, which defines the inside edge of the overlay layer |

Numeric |

0.0 |

|

Outside Trim Point |

Offset of the outside trim point, which defines the outside edge of the overlay layer |

Numeric |

0.0 |

|

Overlay Slope Options |

Slope of the overlay layer. This can be specified with the following options: a) to match slope from inside sample point to outside sample point or, b) outside lane superelevation slope of the baseline alignment. If the inside points are left of the outside points, then left side superelevation specification is used; otherwise right side. a) User Defined; b) Match slope; c) Outside lane superelevation. |

Selection list |

Match slope. |

|

Default Slope |

Specifies user defined slope. Also can be used if match points or superelevation slope doesn’t return appropriate value. |

Numeric, grade |

- 2.0 % |

|

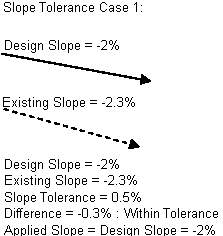

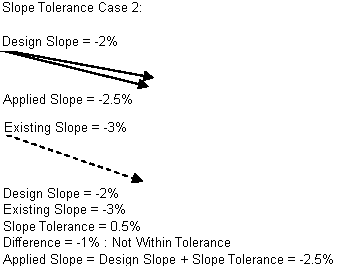

Slope Tolerance |

The value that the Overlay Slope is allowed to vary from its design value. The slope tolerance is not used if the Overlay Slope is given as M (see Behavior below for details). |

Numeric, positive |

0.5% |

|

Use Profile |

Selects whether to hold the top of overlay at the inside trim point to the corridor profile elevation, or to set the vertical placement of the overlay layer based on the Minimum Clearance value |

Selection List |

Use minimum clearance |

|

Minimum Clearance (+/-) |

The minimum vertical clearance between the existing surface and the bottom of the overlay layer. A positive value places the bottom-of-overlay link above the existing surface, creating a Leveling layer beneath the overlay. A negative value places the bottom-of-overlay link below the existing surface, creating a Milling layer that coincides with a portion of the Overlay layer. |

Numeric |

0.100 m 0.30 ft |

|

Overlay Depth |

The thickness of the overlay layer |

Numeric, positive |

0.100 m 0.30 ft |

Target Parameters

This section lists the parameters in this subassembly that can be mapped to one or more target objects, such as a surface, alignment, or profile object in a drawing. For more information, see To Specify Corridor Targets.

|

Parameter |

Description |

Status |

|---|---|---|

|

Existing Surface |

Name of the Surface defining the existing roadway. The following object types can be used as targets for specifying this surface: surfaces. |

Required |

|

Inside Sample Point Offset |

May be used to override the fixed Inside Sample Point Offset and tie the point to an offset alignment. The following object types can be used as targets for specifying this offset: alignments, polylines, feature lines, or survey figures. |

Optional |

|

Outside Sample Point Offset |

May be used to override the fixed Outside Sample Point Offset and tie the point to an offset alignment. The following object types can be used as targets for specifying this offset: alignments, polylines, feature lines, or survey figures. |

Optional |

|

Inside Trim Point Offset |

May be used to override the fixed Inside Trim Point Offset and tie the point to an offset alignment. The following object types can be used as targets for specifying this offset: alignments, polylines, feature lines, or survey figures. |

Optional |

|

Outside Trim Point Offset |

May be used to override the fixed Outside Trim Point Offset and tie the point to an offset alignment. The following object types can be used as targets for specifying this offset: alignments, polylines, feature lines, or survey figures. |

Optional |

Output Parameters

|

Parameter |

Description |

Type |

|---|---|---|

|

Superelevation Axis of Rotation |

Indicates whether the subassembly supports the axis of rotation calculation. To view a description of the parameter, in the Properties window, hover the cursor over the parameter. For more information, see Profile Grade Line Adjustments During Superelevation. |

Static (Description) |

|

%Slope |

The slope used for applying the overlay layer. |

Numeric |

Behavior

This subassembly inserts parallel links defining the top and bottom of an overlay layer. The links are inserted from the Inside Trim Offset to the Outside Trim Offset.

Overlay Slopes

The slope of the Existing Surface is determined between the inside and outside sample points. The slope of the overlay layer is determined by the following steps:

- If the Overlay %Slope input is given as M, then the overlay slope matches the slope from the Inside Sample Point to the Outside Sample point.

- If the Overlay %Slope is given as S, then the overlay uses the outside lane superelevation slope defined for the corridor alignment. The left side slope is used if the Outside Sample Point is to the left of the Inside Sample Point, otherwise the right side superelevation slope is used.

- If a numeric value is given for the Overlay %Slope, the given value is used.

- If a numeric value or the superelevation slope is used, the overlay slope is compared to the existing slope between the sample points. If the difference exceeds the Slope Tolerance value, the design slope is adjusted up or down by the Tolerance value to make it more closely match the existing slope and minimize the amount of leveling or milling. Slope adjustment does not occur if the Slope Tolerance is zero.

Overlay Elevations

The elevations of the overlay points are determined as follows:

- If the Use Profile value is True, the elevation of the corridor profile is held at the Inside Trim offset on the top of overlay. The overlay is extended at the overlay slope to the Outside Trim offset, and a parallel link is inserted for the bottom-of-overlay. Any areas above the existing surface and below the bottom-of-overlay are stored as closed shapes with code “Level”. Areas below the existing surface and above the bottom-of-overlay are stored as closed shapes with code “Mill”.

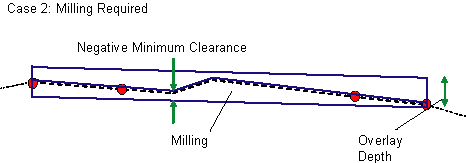

- If the Use Profile value is False, the bottom-of-overlay link is shifted vertically to hold to the Minimum Clearance above or below the existing surface. A positive Minimum Clearance creates a leveling area above the existing surface and below the bottom-of-overlay. A negative clearance creates a milling area below the existing surface and above the bottom-of-overlay.

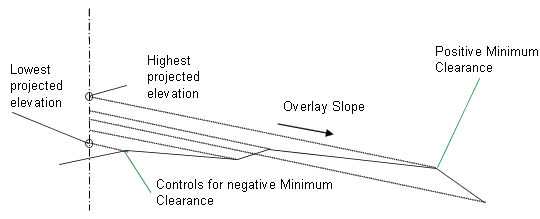

Minimum Clearance Point

The method of determining the point where the Minimum Clearanceapplies is shown in the diagram below.

- A vertical projection line is established at any arbitrary offset.

- Each point on the Existing Surface between the two trim points is projected back to the projection line at the Overlay Slope.

- The point with the highest elevation on the projection line is the control point for a Minimum Clearance value greater than zero. The one with the lowest is the control point for a Minimum Clearance value less than zero.

Layout Mode Operation

In layout mode, this subassembly displays the overlay layer positioned from any convenient point of attachment at a slope of -2%.

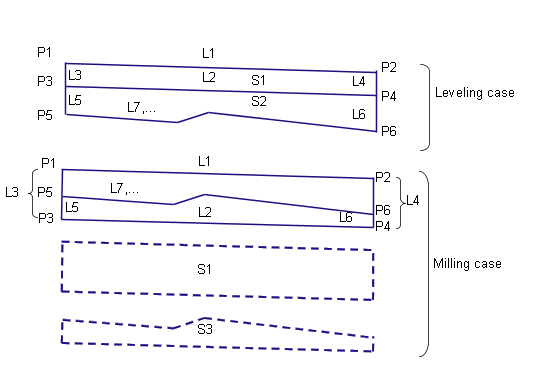

Point, Link, and Shape Codes

The following table lists the point, link, and shape codes for this subassembly that have codes assigned to them. Point, link, or shape codes for this subassembly that do not have codes assigned are not included in this table.

|

Point, Link, or Shape |

Code |

Description |

|---|---|---|

|

P1, P2 |

EOV |

Overlay edges on finish grade |

|

P3, P4 |

EOV_Overlay |

Edges of bottom-of-overlay |

|

L1 |

Top, Pave |

Top of overlay |

|

L2, L3, L4 |

Overlay |

Overlay links. Note that L3, L4 go from the bottom-of-overlay to top-of-overlay in both the Leveling and Milling cases |

|

L5, L6 |

Level Mill |

For the Leveling case For the Milling case |

|

S1 |

Overlay |

Area between the top and bottom of overlay. This overlaps the milling area (S3) for the Milling case as shown in the Coding Diagram below. |

|

S2 |

Level |

Area above existing surface and below the bottom of overlay (Leveling case) |

|

S3 |

Mill |

Area below the existing surface and above the bottom of overlay (Milling case). This area overlaps the Overlay area as shown in the Coding Diagram below. |

Coding Diagram