Composite Tube Problem Description

Demonstrate the effects of using pre-failure nonlinearity with a composite tube structure.

While a single element is useful for demonstrating the shear stress/strain response of a composite material, it is not practical in the sense that actual structures are not modeled using a single element. Use the composite tube to demonstrate the effects of pre-failure nonlinearity on a more realistic structure.

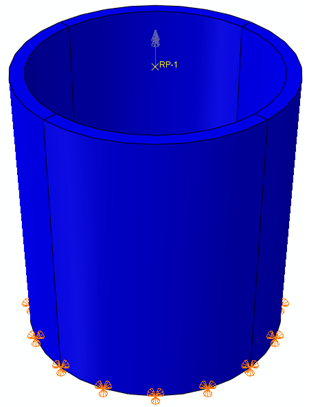

The tube shown below has an inner radius of 50 mm, a wall thickness of 5.9 mm, and a length of 120 mm. A boundary condition is applied to the bottom surface that restricts displacement in all directions. A moment is applied to the reference point shown below and a constraint links the reference point to the top surface so the tube is loaded in torsion. A unidirectional layup is used with the fibers oriented in the hoop direction and SilEglass1200tex-MY750 is the material. Reduced integration solid elements (SOLID185) are used with one integration point through the thickness.