UDMGINI3

UDMGINI3 allows you to define the onset of damage initiation in a plain weave composite.

Damage initiation can be defined at the constituent level (fiber and matrix of each tow) or at the composite level. This routine is called at every equilibrium iteration for every integration point of the woven composite material for which you requested a user damage initiation routine. Here is a template for the interface to UDMGINI3. Note that this subroutine will be called until fiber failure is predicted.

SUBROUTINE UDMGINI3(HMAT, HPROP, NPROPS, PROPS, NSDV, SDV, STRAIN, STRESS, DFGRD, DELT, LE, FI, SR, IFAIL, MSTATE)

USE HELIUS

IMPLICIT NONE

INTEGER(HANDLE), INTENT(IN) :: HMAT

INTEGER(HANDLE), INTENT(IN) :: HPROP

INTEGER, INTENT(IN) :: NPROPS

INTEGER, INTENT(IN) :: NSDV

INTEGER, INTENT(IN) :: IFAIL(8)

INTEGER, INTENT(IN) :: MSTATE

REAL(8), INTENT(IN) :: PROPS(NPROPS)

REAL(8), INTENT(IN) :: STRAIN(6,8)

REAL(8), INTENT(IN) :: STRESS(6,8)

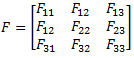

REAL(8), INTENT(IN) :: DFGRD(3,3)

REAL(8), INTENT(IN) :: DELT

REAL(8), INTENT(IN) :: LE

REAL(8), INTENT(INOUT) :: FI(4)

REAL(8), INTENT(INOUT) :: SR(4)

REAL(8), INTENT(INOUT) :: SDV(NSDV)

... user coding to upate FI, SR, and SDV here ...

RETURN

ENDSUBROUTINEVariables Provided for Information

- HMAT

A handle to the current material. This is passed to informational routines (Informational Routines) to access information about the material.

- HPROP

A handle to the current material properties. This is passed to informational routines (Informational Routines) to access information about the material properties.

- NPROPS

- NSDV

- IFAIL

- The failure state of the composite and all constituents (fill, warp, matrix pocket, fill matrix, fill fiber, warp matrix, warp fiber). The table below shows the combinations of constituent failure that lead to each composite damage state. For the fill and warp tow, 1 = no failure, 2 = matrix failure, and 3 = fiber failure. For the remainder of the constituents, 1 = no failure, 2 = failure.

IFAIL(1) Composite 1 2 3 4 5 6 7 8 9 IFAIL(2) Fill Tow 1 2 1 2 3 1 3 2 3 IFAIL(3) Warp Tow 1 1 2 2 1 3 2 3 3 IFAIL(4) Matrix Pocket 1 1 1 2 2 2 2 2 2 IFAIL(5) Fill Fiber 1 1 1 1 2 1 2 1 2 IFAIL(6) Fill Matrix 1 2 1 2 2 1 2 2 2 IFAIL(7) Warp Fiber 1 1 1 1 1 2 1 2 2 IFAIL(8) Warp Matrix 1 1 2 2 1 2 2 2 2 - MSTATE

- PROPS

- The user properties specified by the *USER PROPERTIES keyword in the HIN file.

- STRAIN

The current total strain (mechanical and thermal) of the composite, matrix, and fiber. The first column (STRAIN(:,1)) contains the composite strain. Strains are ordered as such: ε11, ε22, ε33, γ12, γ13, γ23. Columns 2-8 contain the strains for the following constituents:

Strains are oriented in the local coordinate system of their respective tow (1-axis parallel to the length of the tow, 2-axis transverse to the tow and in-plane of the weave). The matrix pocket strains are oriented in the local coordinate system of the fill tow. The fiber direction specified in the material definition does not affect the orientation of the strains (and stresses).

- STRESS

- DFGRD

- DELT

- LE

Variables Updated by the User

- FI

Failure indices. The first value (FI(1)) is the failure index of the fill matrix, the second value is the failure index of the fill fiber, the third for the warp matrix, and the fourth for the warp fiber. If any value equals or exceeds one, that constituent is determined to have initiated damage and will be degraded appropriately. If only the matrix constituent is failed, this subroutine will still be called to predict damage initiation in the fiber. Once all constituents have failed, this subroutine will no longer be called.

- SR

Strength Ratio. The first value (SR(1)) is the strength ratio of the fill matrix, the second value is the strength ratio of the fill fiber, the third for the warp matrix, and the fourth for the warp fiber. The strength ratio is synonymous with the factor of safety or the margin of safety. A strength ratio less than or equal to one indicates the particular constituent has failed. A strength ratio of two indicates the factor of safety is two for the particular constituent. It is best to set this to a large number (>1) for implicit analyses. The strength ratio is used for strain rate strengthening effects in explicit finite element analyses.

- SDV