Input File Keywords

Keywords are presented as parents first and their child keywords following (if they have any). Any keywords on the same level are not presented in any particular order. A parameter enclosed within square brackets indicates an optional parameter.

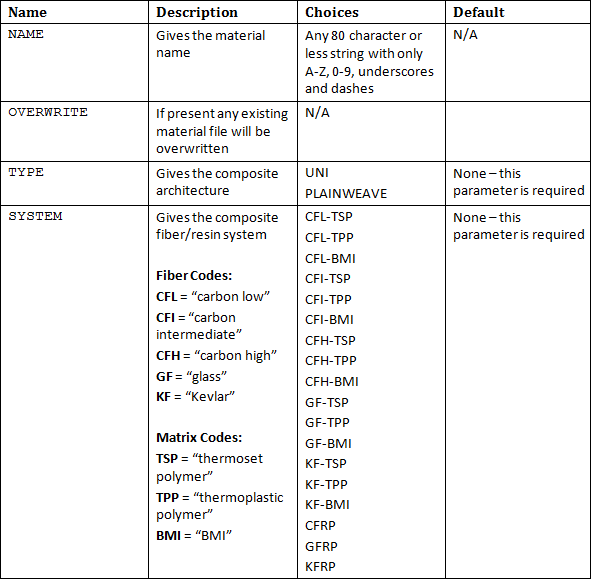

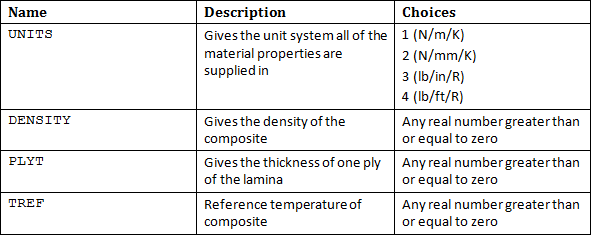

*MATERIAL

At least one *MATERIAL keyword must be present. This keyword defines a new material to be solved for.

*MATERIAL

UNITS, DENSITY, PLYT, TREFParameters:

Data:

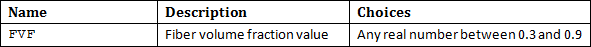

*FVF

The *FVF keyword is a child of *MATERIAL and must be present. This keyword supplies fiber volume fraction information. For unidirectional materials, FVF represents the total fiber volume fraction for the composite. For woven materials, FVF specifies the tow fiber volume fraction.

*FVF

FVFParameters:

NONE

Data:

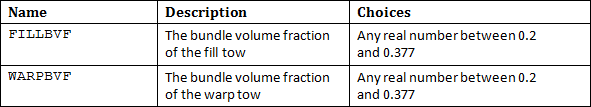

*BVF

The *BVF keyword is a child of *MATERIAL and must be present for plain weave materials (Note: satin fabric materials are not supported in batch mode). This keyword supplies the bundle volume fraction information.

*BVF

FILLBVF, WARPBVFParameters:

NONE

Data:

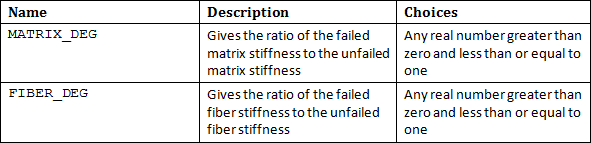

*DEGRADATION

The *DEGRADATION keyword is a child of *MATERIAL and must be present for plain weave materials. This keyword supplies the ratios of failed stiffness to virgin stiffness of the matrix and fiber constituents.

*DEGRADATION

MATRIX_DEG, FIBER_DEGParameters:

NONE

Data:

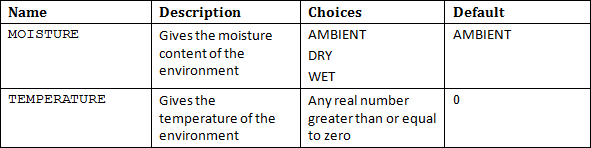

*ENVIRONMENT

The *ENVIRONMENT keyword is a child of *MATERIAL. At least one *ENVIRONMENT keyword must be specified for each *MATERIAL. This keyword begins the definition of an environment containing a set of material properties for the current material.

*ENVIRONMENT, MOISTURE=AMBIENT/DRY/WET, TEMPERATURE=TEMPParameters:

Data:

NONE

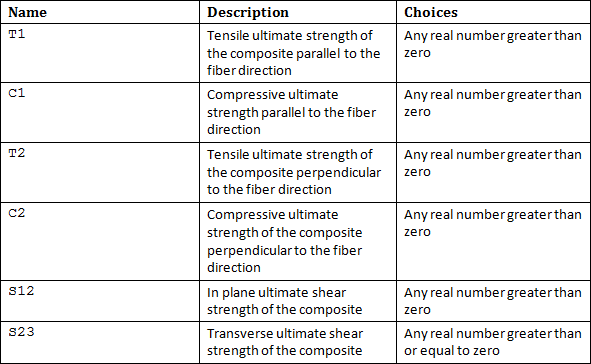

*STRENGTHS

The *STRENGTHS keyword is a child of *ENVIRONMENT. For unidirectional composites the *STRENGTHS keyword data is:

*STRENGTHS

T1, C1, T2, C2, S12, S23Parameters:

NONE

Data:

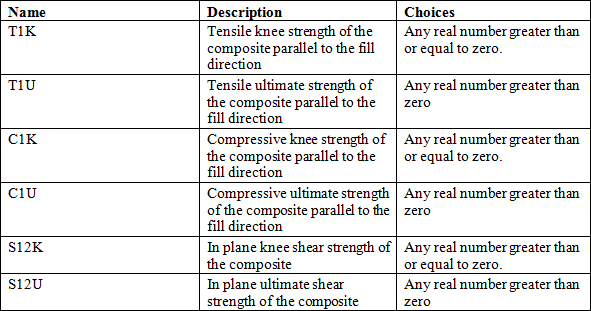

For plain weave composites the *STRENGTHS keyword data is:

*STRENGTHS

T1K, T1U, C1K, C1U, S12K, S12UParameters:

NONE

Data:

*LAMINA

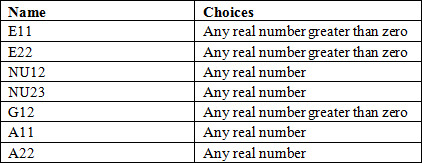

The *LAMINA keyword is a child of *ENVIRONMENT and is required. This keyword gives the target elastic constants of the lamina. For unidirectional composites the material is assumed to be transversely isotropic with respect to the 2-3 plane. The data for *LAMINA for a unidirectional composite is:

*LAMINA

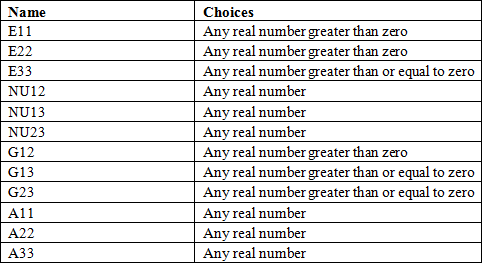

E11, E22, NU12, NU23, G12, A11, A33For plain weave composites the material is assumed to be orthotropic. If all material properties are known they can be supplied. Otherwise, the following properties can be supplied as zero and will be calculated by CMM: E33, NU13, NU23, G13, G23, and A33. The data for *LAMINA for a plain weave composite is:

*LAMINA

E11, E22, E33, NU12, NU13, NU23, G12, G13, G23, A11, A22, A33Parameters:

NONE

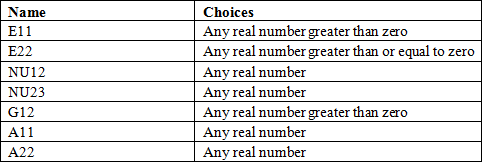

Data:

*FIBER

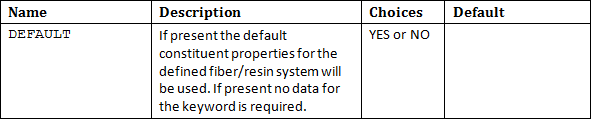

The *FIBER keyword is a child of *ENVIRONMENT and is required. This keyword gives the starting elastic constants of the fiber constituent. The fiber is assumed to be transversely isotropic with respect to the 2-3 plane.

*FIBER, [DEFAULT]

E11, E22, NU12, NU23, G12, A11, A33Parameters:

Data:

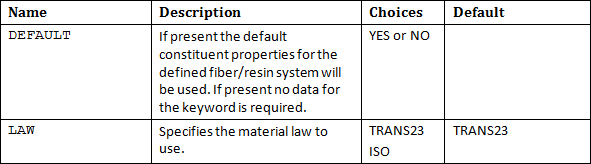

*MATRIX

The *MATRIX keyword is a child of *ENVIRONMENT and is required. This keyword gives the starting elastic constants of the matrix constituent.

*MATRIX, [DEFAULT], [LAW=TRANS23/ISO]

E11, E22, NU12, NU23, G12, A11, A33If LAW=ISO the data for the *MATRIX keyword is:

*MATRIX, LAW=ISO

E, NU, AParameters:

Data:

*NLSHEAR

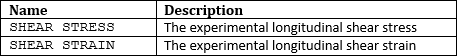

The *NLSHEAR keyword is a child of *ENVIRONMENT. It is an optional keyword used to define the experimental longitudinal shear stress and strain data for the lamina.

Parameters:

NONE

Data:

The stress-strain data is entered as comma-separated pairs. The data provided must equal or exceed the supplied lamina longitudinal shear strength (+S12).

*NLSHEAR

stress_1, strain_1

stress_2, strain_2

...

stress_n, strain_n*SOLVE

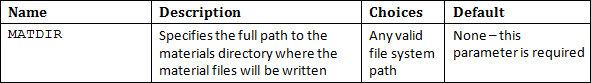

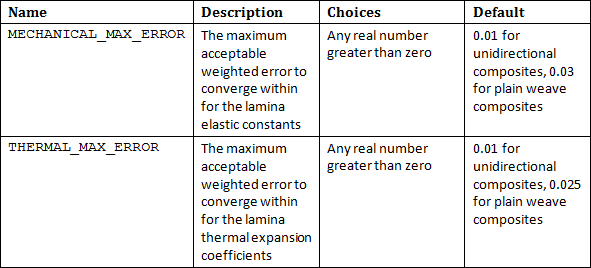

One (and only one) *SOLVE keyword must be present. This keyword gives the settings for the solving and output process.

*SOLVE, MATDIR=MATDIR

MECHANICAL_MAX_ERROR, THERMAL_MAX_ERRORParameters:

Data:

*FATIGUE

The *FATIGUE keyword is a child of *ENVIRONMENT. This keyword begins the definition of a material containing fatigue data.

Parameters:

NONE

Data:

NONE

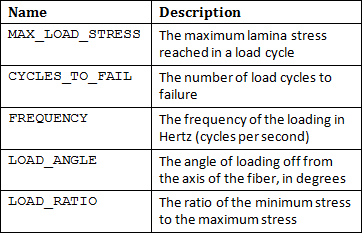

*SNDATA

The *SNDATA keyword is a child of *FATIGUE. This keyword begins the definition of the S-N fatigue data.

Parameters:

NONE

Data:

At least two data lines at a 0-2° load angle and two data lines at a 2-90° load angle are required to perform the optimization.