Weld bead features capture the weld specification, associate it with selected geometry, and display a weld symbol.

Weld bead features in Inventor include a cosmetic weld, a solid fillet weld, and a solid groove weld. All weld bead types reside only in the Welds feature group. Each is represented with a unique icon in the browser.

Cosmetic and solid welding symbols can be recovered and created automatically in drawing views. You can also automatically generate caterpillar annotations for solid body fillet welds.

You can create a welding symbol simultaneously with the weld bead or you can create it in a separate operation.

How are cosmetic welds and solid welds different?

Cosmetic welds are created as graphical elements. These graphical elements change the appearance of model edges to indicate they were welded. Cosmetic welds also create a standard weld symbol containing a full description of the weld feature. It does not create the actual weld bead geometry, and when calculated for mass properties, contributes an approximate mass. Because of these characteristics, cosmetic welds can easily represent a wide range of weld types.

Solid welds use the weld specification to create a 3D representation of the weld bead and a weld symbol on the assembly weldment. The solid weld bead adds material to the model that contributes to the mass property calculations. Use solid welds for design cases where interference checking or the effects of welds on mass properties are a concern.

Different weld types and values can be defined for both the arrow side and other side of a cosmetic weld. Arrow side and other side definitions for a solid weld can only differ in value.

How is the workflow different for cosmetic welds and solid welds?

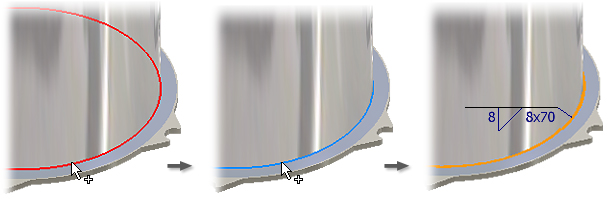

Complete control of weld specification capabilities is available for all weld feature types. The main difference is that you select edges to create a cosmetic weld, and faces to create a solid weld.

Weld preparations are optional for solid welds, but are not required for cosmetic welds. The cosmetic weld symbol contains the description of weld preparations required for the selected edges.