Dynamic Equivalent Radial Load:

That constant stationary load under the influence of which a rolling bearing has the same life as it attains under the actual load conditions. The dynamic equivalent radial load for radial and angular contact ball bearings and radial roller bearings, under constant radial, and axial loads, is given by

P r = (X F r + Y F a ). f d

The dynamic equivalent radial load for radial roller bearings with α = 0, and subjected to radial load only, is given by

P r = F r f d

Dynamic Equivalent Axial Load:

That constant centric axial load under the influence of which a rolling bearing has the same life as it attains under the actual load conditions. The dynamic equivalent axial load for thrust ball bearings and thrust roller bearings with α ≠ 0 is given by

P a = (X F r + Y F a ). f d

Thrust ball and roller bearings with α = 90 deg. can support axial loads only. The dynamic equivalent axial load for this type of bearings is given by

P a = F a f d

Static Equivalent Radial Load:

Static radial load which causes the same contact stress at the center of the most heavily loaded rolling element/raceway contact as the contact that occurs under the actual load conditions. The static equivalent radial load for radial and angular contact ball bearing and radial roller bearing is the greater of the two values given by

P 0r = X 0 F r + Y 0 F a

P 0r = F r

Static Equivalent Axial Load:

Static centric axial load which would cause the same contact stress at the center of the most heavily loaded rolling element/raceway contact as the contact that occurs under the actual load conditions. The static equivalent axial load for thrust ball bearing and thrust roller bearing is given by

P 0a = X 0 F r + Y 0 F a

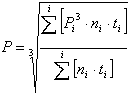

Resultant Equivalent Load

When the bearing load is constant, the equivalent load is given according to bearing type by.

P = P r or P = P a

When the bearing load during service life is not constant, the equivalent load is given by.

where:

|

i |

index of service life time period |

|

|

n i |

service life time period rotates |

|

|

t i |

service life time period duration |

|

|

P i |

service life time period equivalent radial or axial load (according to bearing type) |

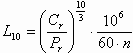

Basic Rating Life:

For an individual rolling bearing, or a group of apparently identical rolling bearings operating under the same conditions, the life associated with 90% reliability, with contemporary, commonly used material and manufacturing quality, and under conventional operating conditions. The basic rating life for radial ball bearing is given by

|

or |

|

for rating life in hours |

The basic rating life for radial roller bearing is given by

|

or |

|

for rating life in hours |

The basic rating life for thrust ball bearing is given by

|

or |

|

for rating life in hours |

The basic rating life for thrust roller bearing is given by

|

or |

|

for rating life in hours |

Adjusted Rating Life:

The rating life obtained by adjustment of the basic rating life for an appropriate reliability level, special bearing properties, and specific operating conditions. The basic rating life for radial ball bearing is given by

for ANSI/AFBMA 9 (ISO 281) calculation method: L nar = L 10r a 1 a 2 a 3 or L na = L 10 a 1 a 2 a 3 for rating life in hours

for SKF AG calculation method: L nar = L 10r a 1 a skf f t or L na = L 10 a 1 a skf f t for rating life in hours

Life Adjustment Factor for Reliability, a1

For a group of apparently identical rolling bearings, operation under the same conditions, the percentage of the group that is expected to attain or exceed a specified life. The reliability of an individual rolling bearings is the probability that the bearing attains or exceeds a specified life. Values of the life adjustment factor a1 are given in next table:

|

Reliability [%] |

L na |

a1 |

|---|---|---|

|

90 |

L 10 |

1 |

|

95 |

L 5 |

0.62 |

|

96 |

L 4 |

0.53 |

|

97 |

L 3 |

0.44 |

|

98 |

L 2 |

0.33 |

|

99 |

L 1 |

0.21 |

Life Adjustment Factor for Special Bearing Properties, a2

The bearing life is extended or shortened according to the quality of the material, the manufacturing technology of the bearing and its internal design. For these bearing life properties, the life value is corrected by the life adjustment factor for special bearing properties a2.

Life Adjustment Factor for Operating Conditions, a3

Using this factor you take into account the effects of operating conditions, especially lubrication on the bearing. the bearing life is affected by the phenomenon of fatigue which occurs, in general, beneath surfaces subjected to repeated stresses. When the lubrication conditions are good when the rolling element and raceway surfaces are separated by an oil film and surface damage can be disregarded, a 3 is set to 1. When conditions of lubrication are not good, for example, when the viscosity of the lubricating oil is low or the peripheral speed of the rolling elements is especially low, and so on, a 3 < 1 is used.

On the other hand, when lubrication is especially good, a value of a 3 > 1 can be used. When lubrication is not good and a 3 < 1 is used, the life adjustment factor a2 cannot be bigger than 1. When you select a bearing according to the basic dynamic load rating, we recommend that a suitable value for reliability factor a1 is chosen for each application. Make the selection using the C/P determined by machine type and based upon the actual conditions of lubrication, temperature, mounting, and so on.

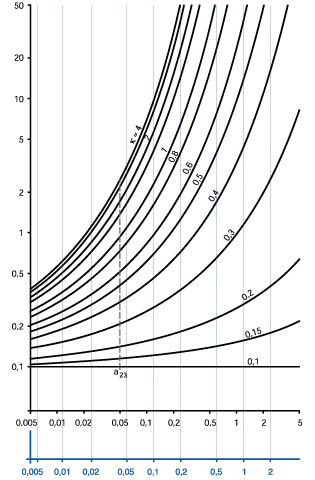

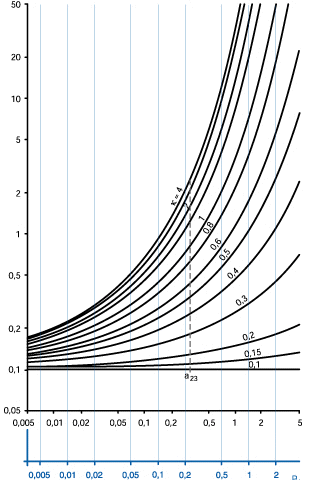

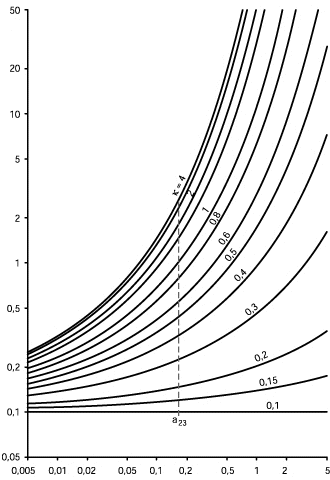

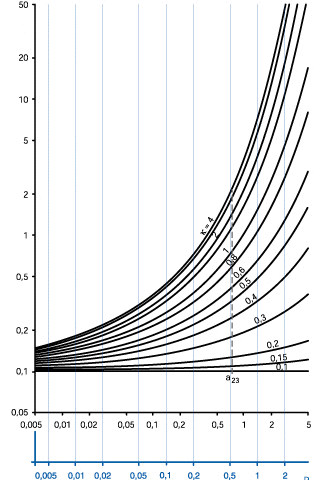

SKF Life modification Factor, aSKF

This factor represents the relationship between the fatigue load limit ratio (Pu/P), the lubrication condition (viscosity ratio) and the contamination level in the bearing (ηc). Values for the factor aSKF can be obtained from four diagrams, depending on bearing type, as a function of ηc(Pu/P) for SKF standard and SKF Explorer bearings and different values of the viscosity ratio κ.

Diagram 1: Factor a SKF for radial ball bearings:

| a SKF |

|

| η c (P u / P) |

|

|

Other SKF Standard Bearings | |

|

|

SKF Explorer Bearings |

Diagram 2: Factor a SKF for radial roller bearings:

| a SKF |

|

| η c (P u / P) |

|

|

Other SKF Standard Bearings | |

|

|

SKF Explorer Bearings |

Diagram 3: Factor a SKF for thrust ball bearings:

| a SKF |

|

| η c (P u / P) |

Diagram 4: Factor a SKF for radial thrust roller bearings:

| a SKF |

|

| η c (P u / P) |

|

|

Other SKF Standard Bearings | |

|

|

SKF Explorer Bearings |

Temperature Factor, ft

The operating temperature for each bearing is determined based on its material and structure. If special heat treatment is performed, bearings can be used at temperatures higher than +150 ºC. The allowable contact stress decreases gradually as the operating temperature increases. The rating life is lowered accordingly.

Power lost by friction

For κ > 4, use curve for κ = 4. As the value of η c (P u / P) tends to zero, a SKF tends to 0.1 for all values of κ. The dotted line marks the position of the old a 23 (κ) scale where a SKF = a 23 .

The diagrams represent typical values and safety factors of the type normally associated with fatigue load limits for other mechanical components. Considering the simplifications inherent of the SKF rating life equations, even if the operating conditions are accurately identified, it is not meaningful to use values of a SKF in excess of 50.

![]()

Meaning of used variables:

|

C r |

basic dynamic radial load rating, [lbforce, N] |

|

|

C or |

basic static radial load rating, [lbforce, N] |

|

|

C a |

basic dynamic axial load rating, [lbforce, N] |

|

|

C oa |

basic static axial load rating, [lbforce, N] |

|

|

Fa |

bearing axial load = axial component of the actual bearing load, [lbforce, N] |

|

|

F r |

bearing radial load = radial component of the actual bearing load[lbforce, N] |

|

|

n |

shaft rotates, [rpm] |

|

|

L regr |

required rating life, in 10 6 revolutions, [Mr] | |

|

L 10r |

basic rating life, in 10 6 revolutions, [Mr] |

|

|

L nar |

adjusted rating life, in 10 6 revolutions, [Mr] |

|

|

L reg |

required rating life, in 10 6 revolutions, [h] | |

|

L 10 |

basic rating life, in 10 6 revolutions, [h] |

|

|

L na |

adjusted rating life, in 10 6 revolutions, [h] |

|

|

P r |

dynamic equivalent radial load, [lbforce, N] |

|

|

P or |

static equivalent radial load, [lbforce, N] |

|

|

P a |

dynamic equivalent axial load, [lbforce, N] |

|

|

P oa |

static equivalent axial load, [lbforce, N] |

|

|

X |

dynamic radial load factor | |

|

X 0 |

static radial load factor | |

|

Y |

dynamic axial load factor | |

|

Y 0 |

static axial load factor | |

|

R reg |

required reliability, [%] |

|

|

a 1 |

life adjustment factor for reliability |

|

|

a 2 |

life adjustment factor for special bearing properties |

|

|

a 3 |

life adjustment factor for operating conditions |

|

|

a SKF |

life adjustment factor based on SKF Life Method |

|

|

e |

limit value of F a / F r for the applicability of different values of factor X and Y |

|

|

P |

exponent for determining life |

|

| α |

nominal contact angle of the bearing, in degrees |

|

|

s 0 |

required static safety factor |

|

|

s 0c |

calculated static safety factor |

|

|

f t |

temperature factor |

|

|

f d |

factor of additional forces |

|

|

l t |

lubrication type |

|

|

T |

maximum working temperature |

|

|

f z |

power lost by friction |

|

| μ |

Friction Factor [MPA,psi] |