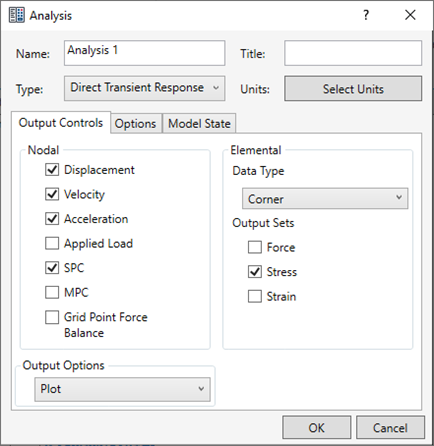

- In the tree view, right-click on Analysis 1 and select Edit.

- Select Direct Transient Response from the Type drop-down menu.

- Check the

Velocity and

Acceleration checkboxes.

- Click OK.

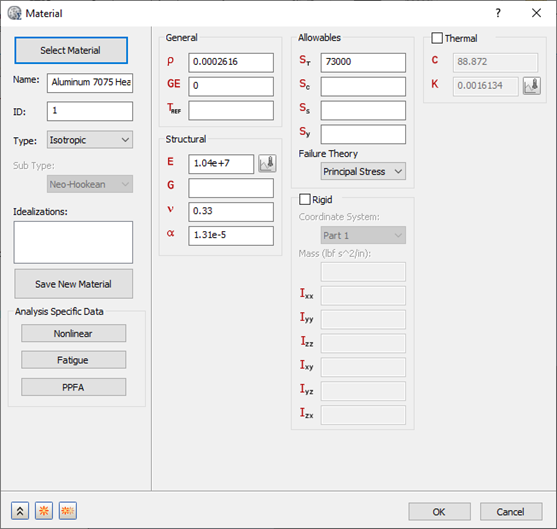

Define Material Properties

- In the Model tree, right-click .

- In the dialog, click Select Material. The Material DB dialog will become populated with the available materials.

- Click on Load Database.

- Browse to C:\Program Files\Autodesk\Inventor Nastran 2024\In-CAD\Materials, and open the ADSK_materials.nasmat file. The material tree is populated with the available materials.

- Under the

Aluminum Alloys category, select

Aluminum 7075 Heat Treated (T6) Wrought.

- Click Close and then OK to create the material.

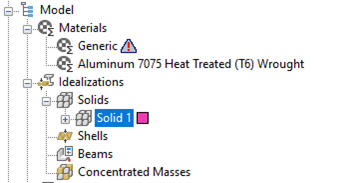

Define Element Properties

- In the

Model tree, under

Idealizations, check for any existing definitions under the standard categories, such as

Solids and

Shells. Solid 1, shown below, is an example of an existing definition:

If there are any existing definitions, right-click . Doing this ensures that you won't have unwanted materials appearing in the part mesh and participating in the analysis.

- In the Model tree, right-click .

- Select Shell Elements from the Type drop-down menu.

- Ensure that Material is set to Aluminum 7075 Heat Treated (T6) Wrought.

- Enter

0.1 in the

t (thickness) field.

- Click OK.

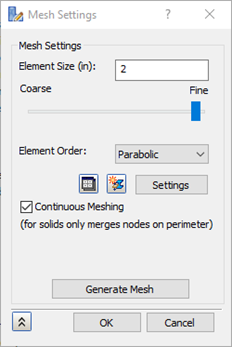

Define the Mesh

- Right-click .

- Type

2.0 in the

Element Size field.

- Click

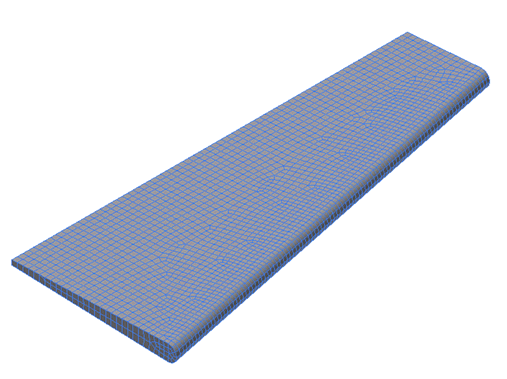

OK to generate the mesh. The mesh should look as shown below.

Typically, it is wise to define a material orientation for shell element models. However, this is not done in this case.

Typically, it is wise to define a material orientation for shell element models. However, this is not done in this case.