Legacy Workflow Tutorials

Video-based learning for intermediate to advanced Alias users.

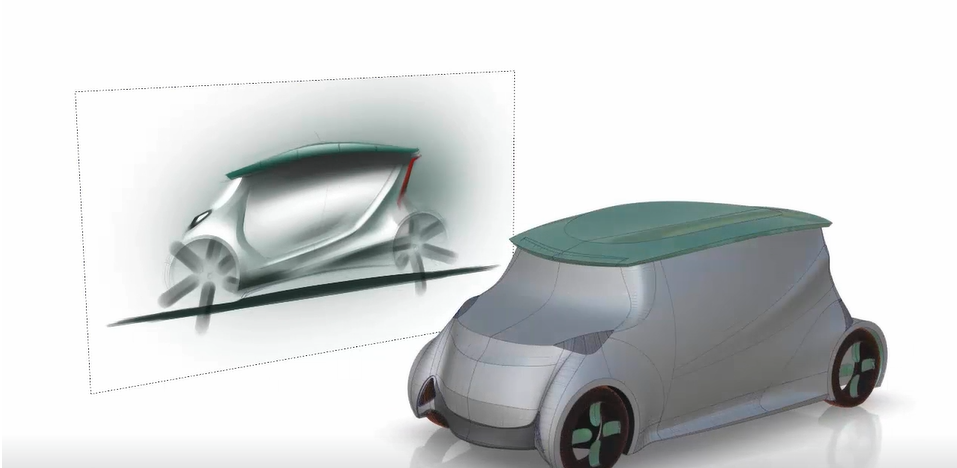

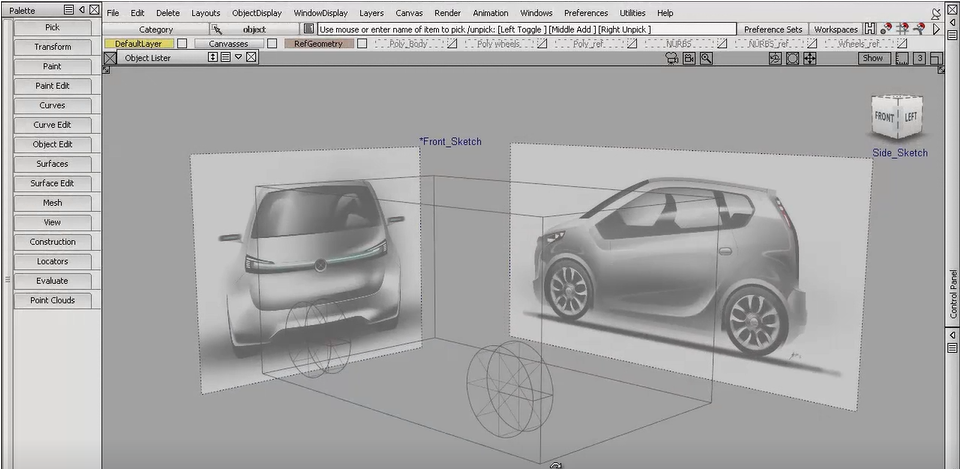

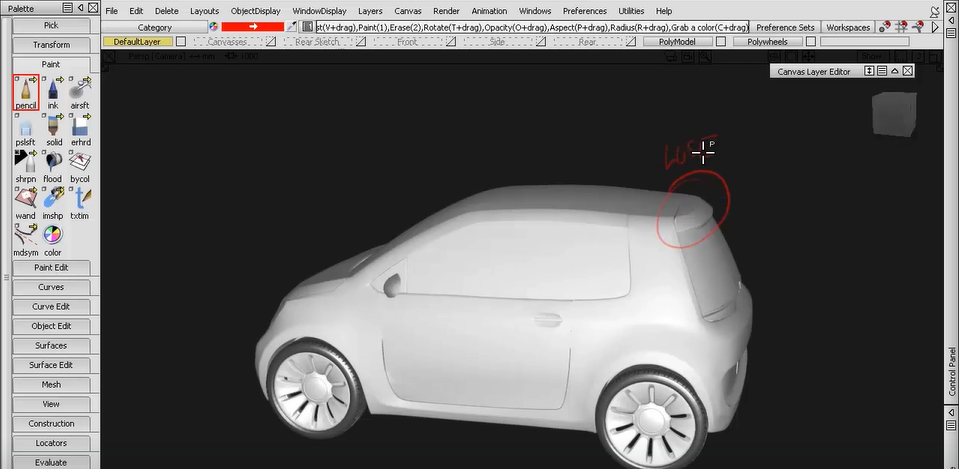

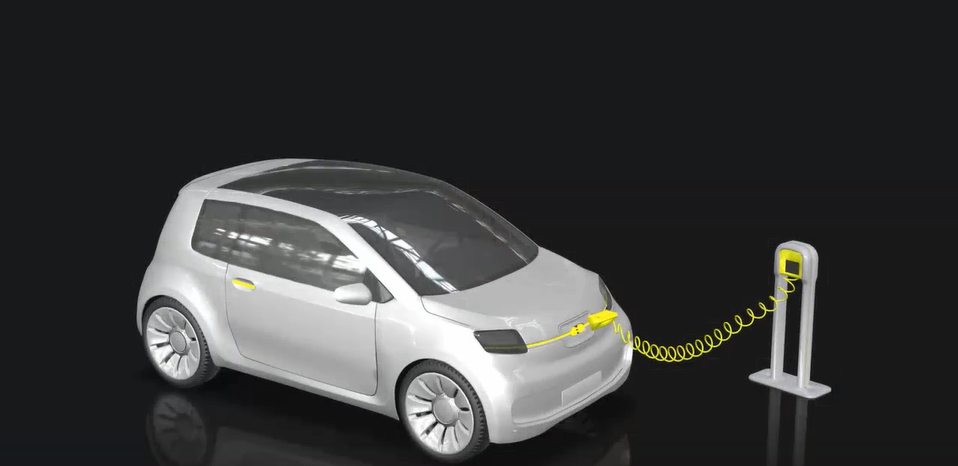

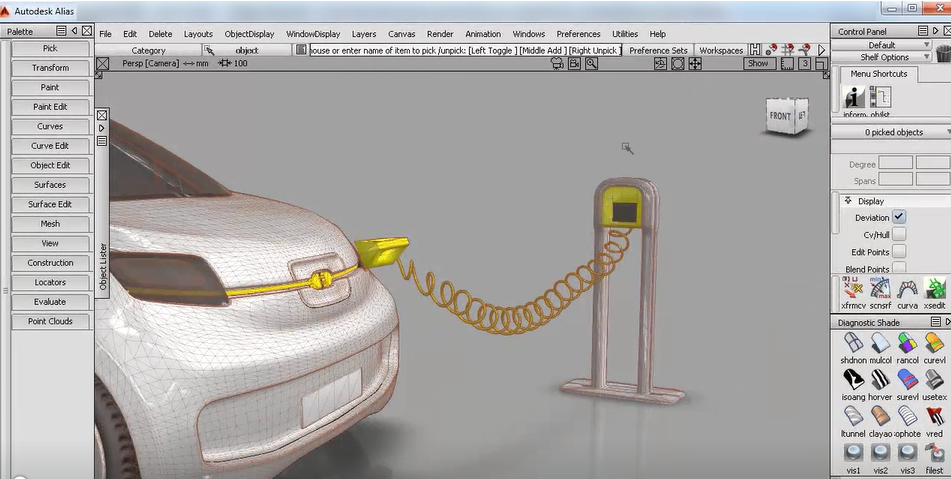

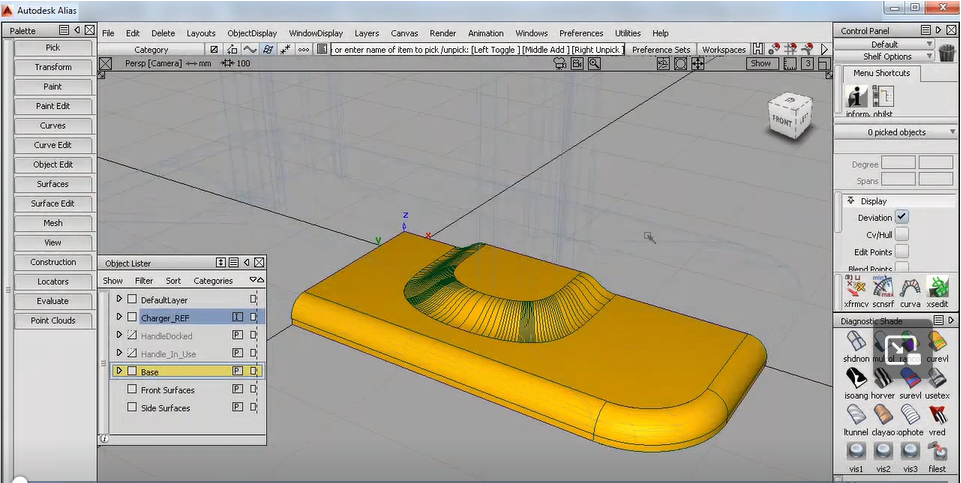

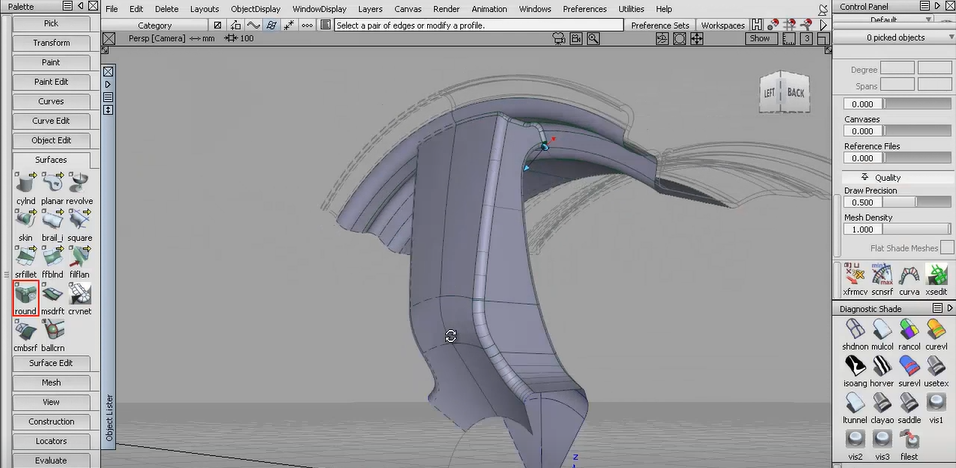

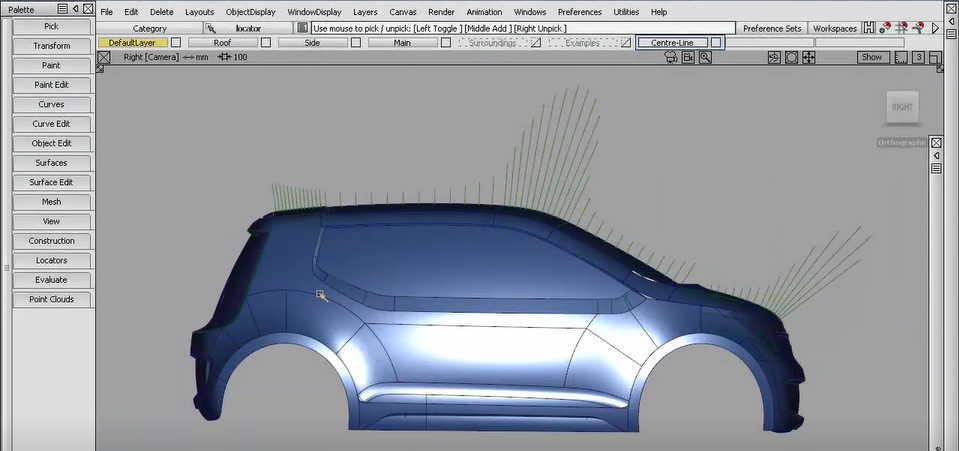

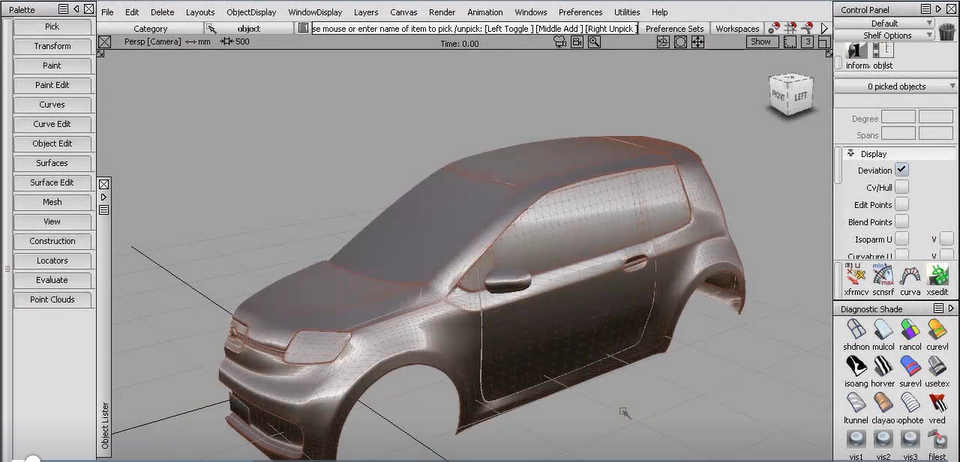

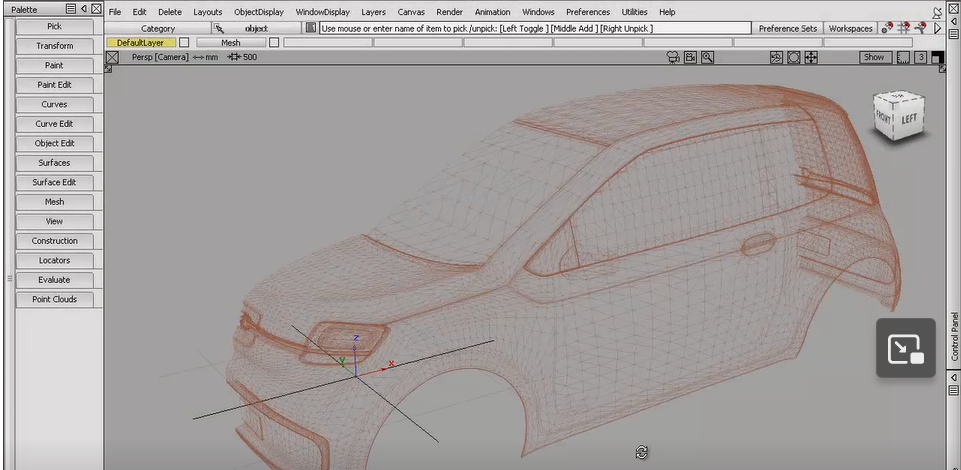

Concept Modeling

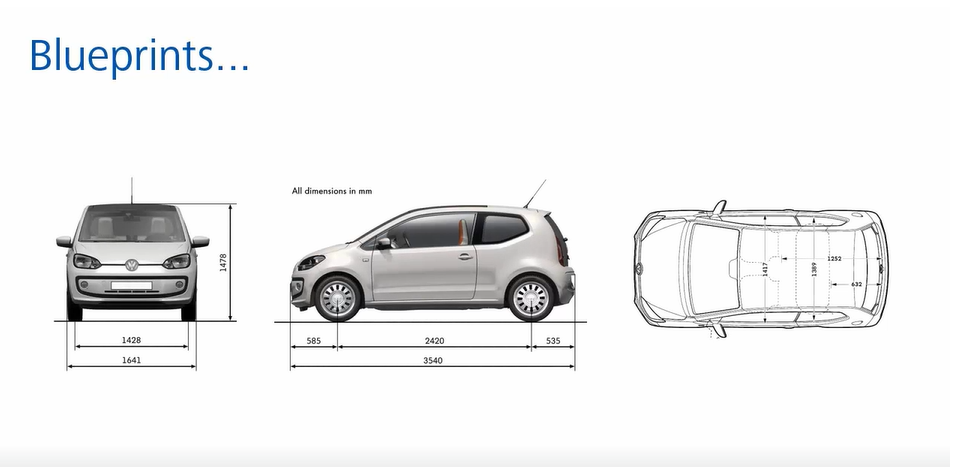

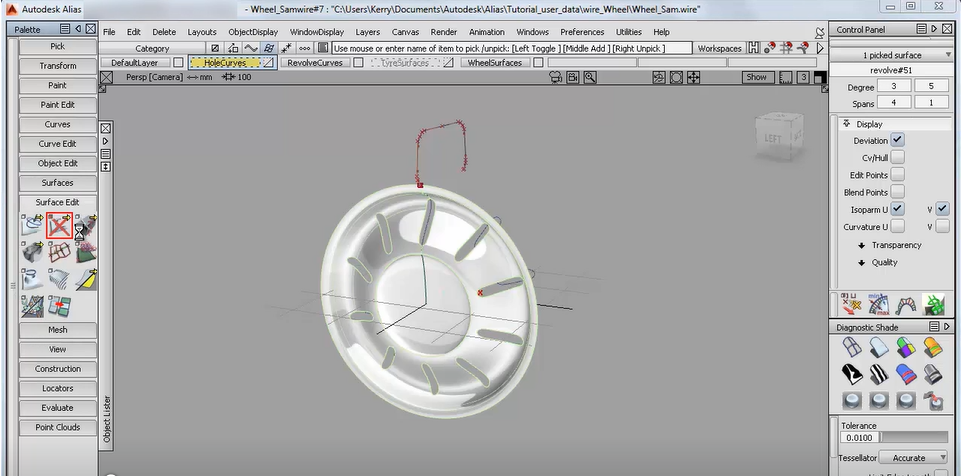

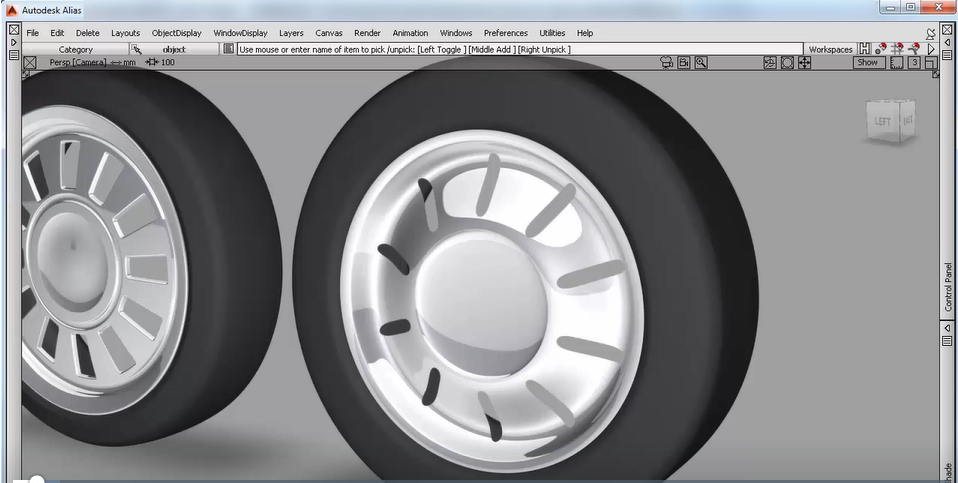

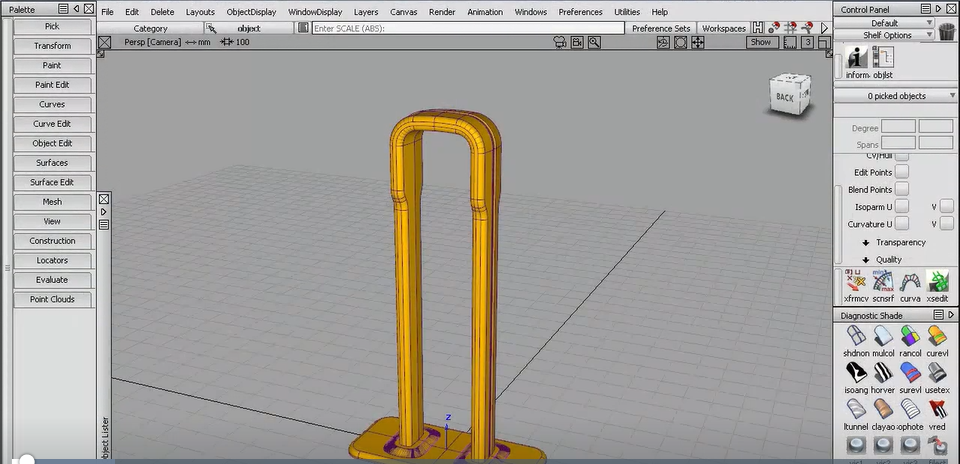

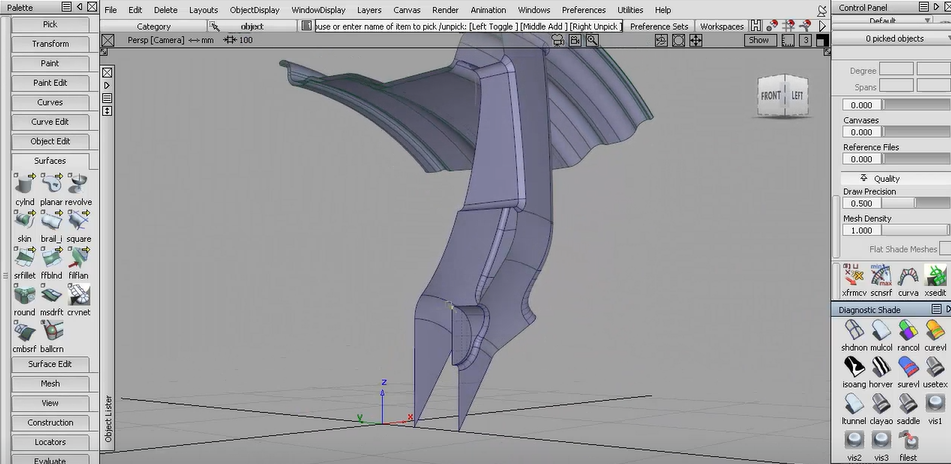

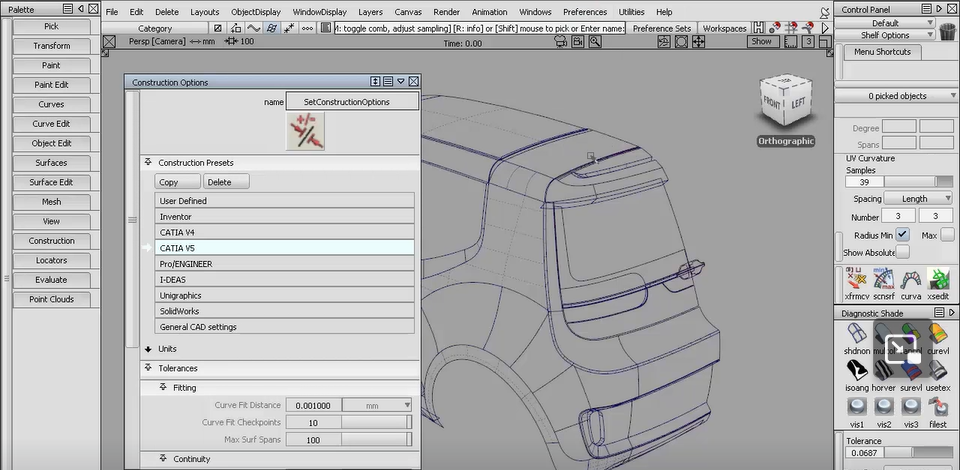

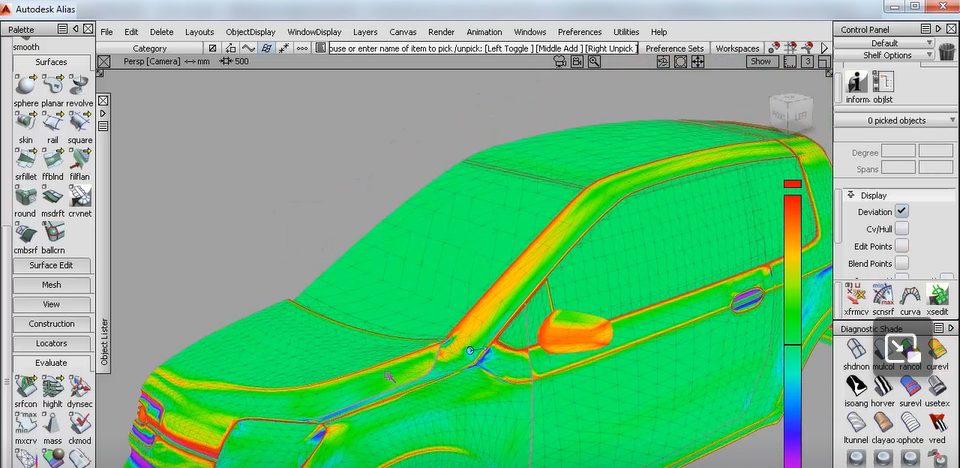

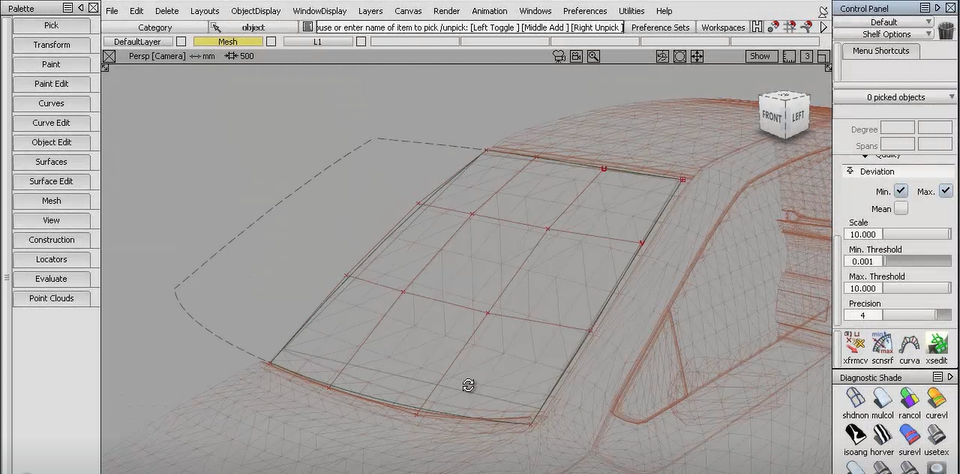

Modeling for Production

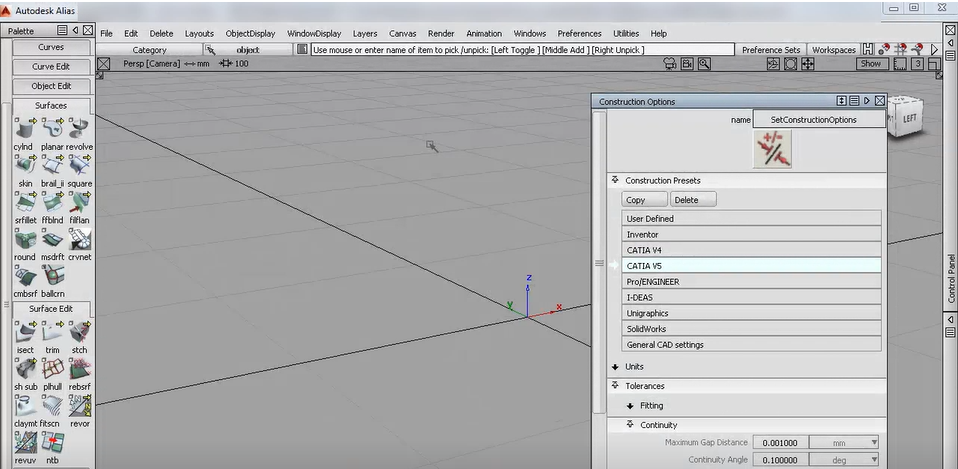

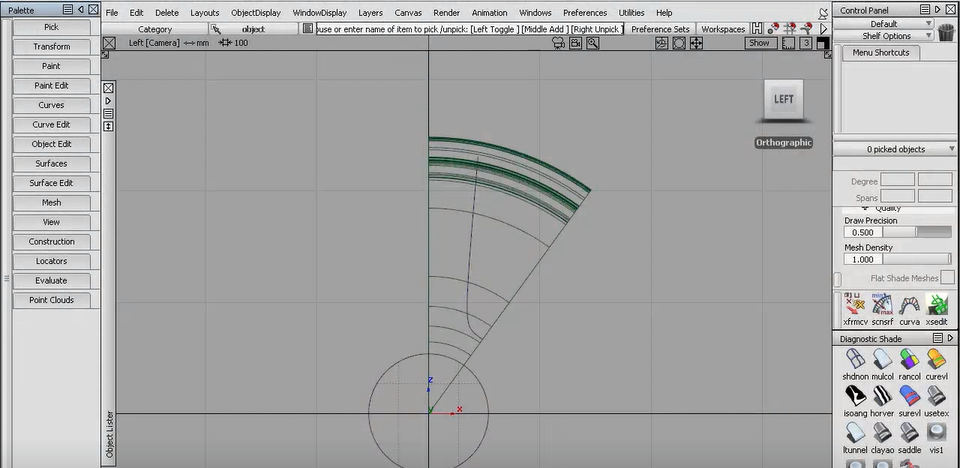

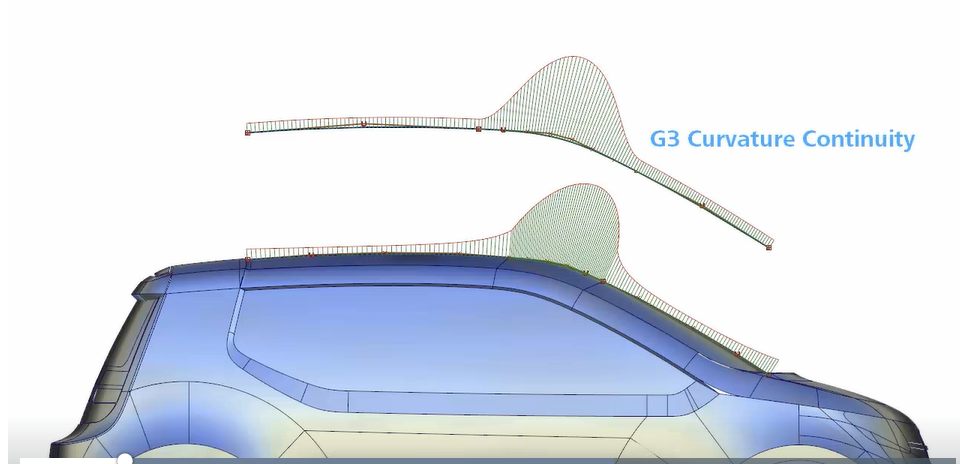

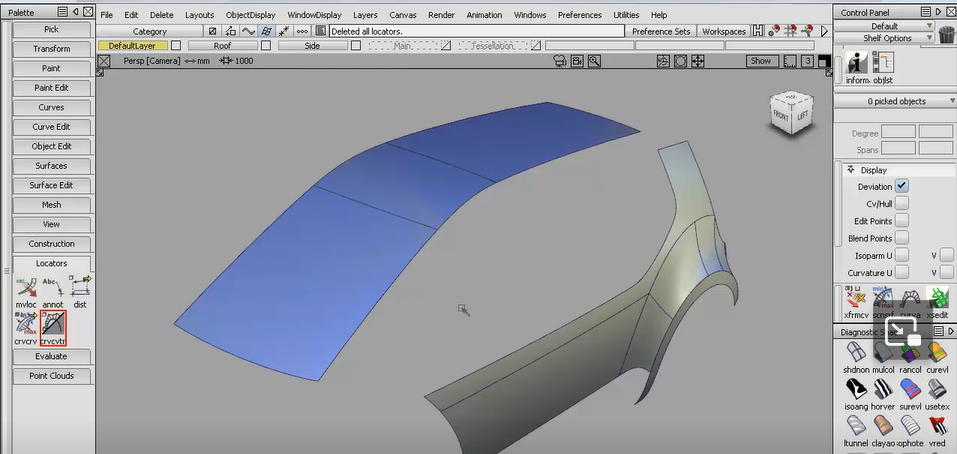

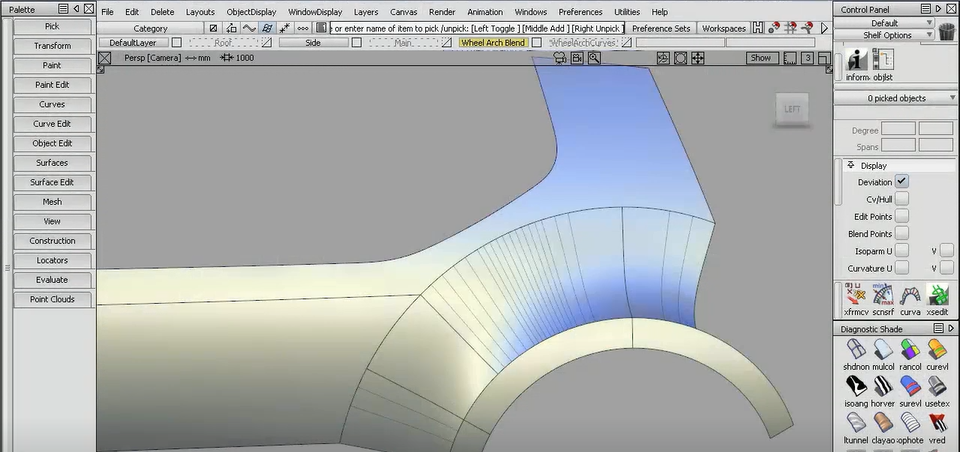

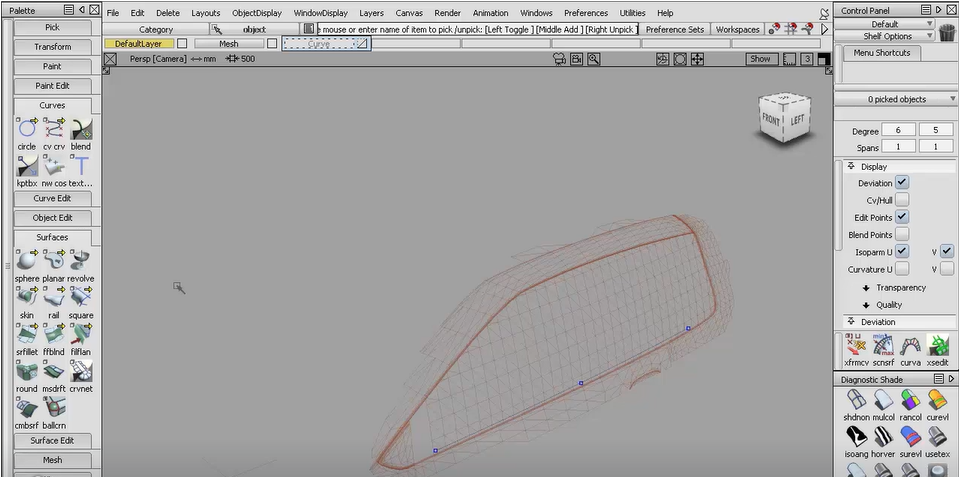

Technical Surfacing

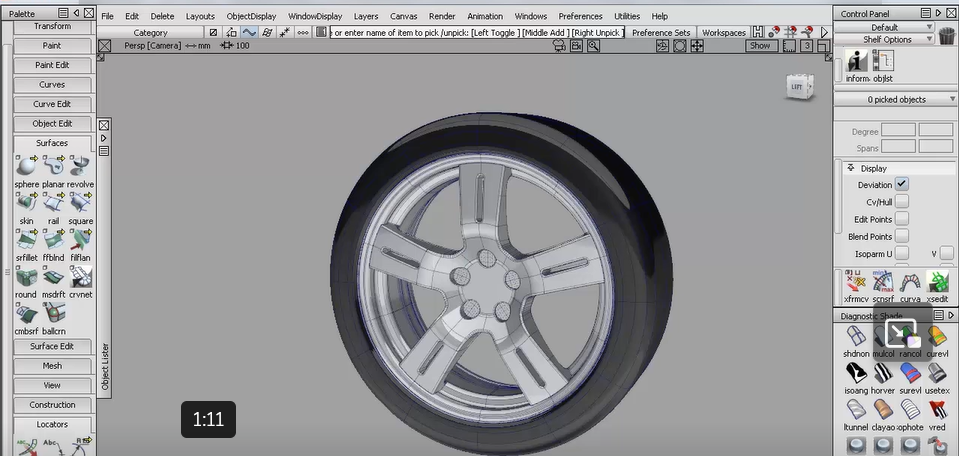

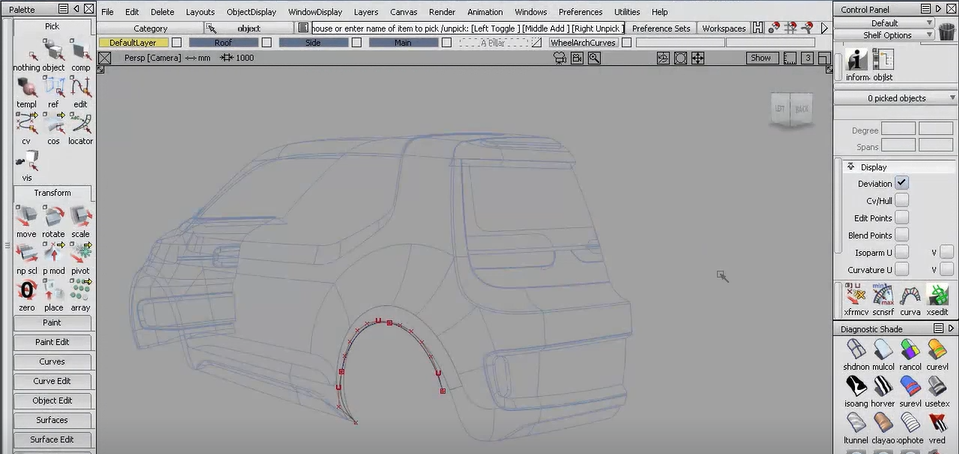

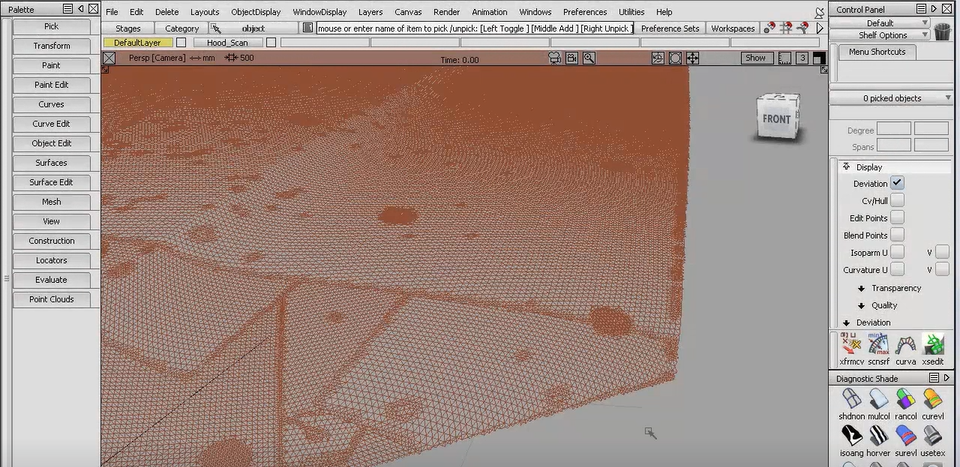

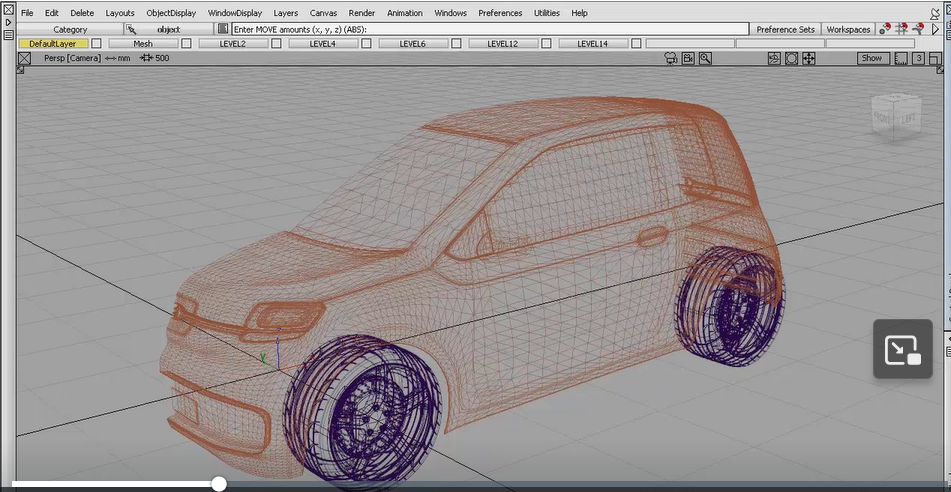

Reverse Engineering

Additional information

- Alias Golden Rules: Best practices for using Alias.

- Theory Builders: Alias theory and concepts.

- Quick Tips: Tips and reminders for using and customizing Alias.

- Resources: Alias update movies (What's New videos) and Align Masterclass videos.