Fatigue Material Characterization Process

Follow the steps below to characterize a material for a fatigue analysis.

After determining the static in situ properties (Determination of the Optimized In Situ Consituent Properties), the following material fatigue characterization process must be carried out for each identifiable fatigue failure mode within the composite lamina. The process is identical for each, so it is only described once. The material fatigue characterization process involves an initial step followed by an iterative step. The following processes define the initial step:

- Read in S-N calibration curves and their corresponding parameters, R, f, and T, and material properties

- Rotate the stress S into the principal coordinate system of the composite to get a composite stress tensor σc

- Extract the matrix stress tensor σm from the composite stress tensor using MCT

- Map the matrix stress tensor to an effective stress depending on the microstructure and whether the loading is on-axis or off-axis.

- Use the value of R to calculate σeff,min = σeff,max.

- Calculate the minimum cycles to failure using Eq. 61 and guesses for Ub,

, Uh, and ψ

, Uh, and ψ - At the conclusion of this initial step, we have three vectors, σeff,max, σeff,min, and Nf, of length i, where i is the total number of data points in the S-N curve(s).

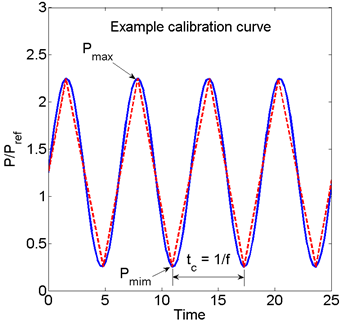

The iterative step of the material fatigue characterization involves adjusting Ub, , Uh, and ψ to minimize the error between the log of the cycles to failure and the log of the predicted number of cycles to failure. Accomplishing this task requires an assumption about the load history. We assume the load history has a saw-toothed shape, as shown by the red curve below. As with the static in situ properties, the gradient method of steepest descent is used to optimize the fatigue parameters.

, Uh, and ψ to minimize the error between the log of the cycles to failure and the log of the predicted number of cycles to failure. Accomplishing this task requires an assumption about the load history. We assume the load history has a saw-toothed shape, as shown by the red curve below. As with the static in situ properties, the gradient method of steepest descent is used to optimize the fatigue parameters.