Save a Unidirectional mdata File

After the data has been entered into the GUI, you are ready to save the data and create an mdata file.

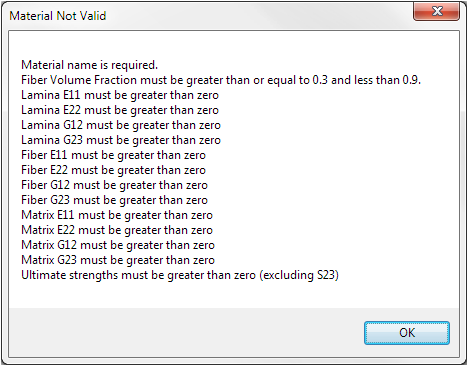

When File > Save As is selected, a check is performed to ensure the required data has been entered and is within appropriate limits. An error message will result if data is entered incorrectly. An example error message is shown below.

Composite Material Manager is used to characterize a material by entering lamina, fiber, and matrix properties. After you input these properties, it iterates on the constituent properties until the computed lamina properties are converged to within a specified tolerance (the default tolerances may be changed by selecting File > Settings). Specifically, Composite Material Manager first iterates on elastic constants (E, ν, and G) to converge on the lamina elastic constants. After the elastic constants are correctly computed, the constituent coefficients of thermal expansion (CTEs) are iterated on until the input lamina CTEs are converged upon to within a specified tolerance. It then stores the converged material properties (mdata.xml) as well as the input material properties (input.xml). The converged material data file is used by Helius PFA because it requires a set of material properties which allow for a correct decomposition of the lamina stress/strain field to the constituent stress/strain fields (for more information, please refer to the Theory Manual). The input material properties are saved for reference and are not used by Helius PFA.

Due to the nature of unidirectional composite materials, dependence exists between elastic constants and CTEs. Therefore, when Composite Material Manager iterates on the constituent CTEs, a small adjustment in the properties can cause a large difference in the computed lamina CTEs. If the input constituent CTEs are close to the correct values, Composite Material Manager will converge on the input lamina CTEs with little effort. However, if the input constituent CTEs do not generate an accurate set of lamina CTEs, the iteration process can cause the stored lamina material properties to be vastly different than those input. The difference is caused by the convergence criterion used in the iteration scheme. Specifically, if the error of the computed CTEs to the input CTEs does not change for multiple iterations, Composite Material Manager will consider the process complete and store the computed lamina CTEs.

You are highly encouraged to check the converged material properties by opening the generated mdata.xml file with Composite Material Manager and verifying that the lamina material properties are acceptable. If the lamina CTE values are not acceptable, it might be necessary to rerun the material characterization process and slightly modify the input constituent CTE values until an acceptable set of lamina CTEs have been generated.