Material Mapping

Map one material ID to another using the HIN file.

In many instances you may choose to analyze a structure with a material which has different options (MATPFA fields) associated with the analysis. For example, you may wish to analyze a region around a stress concentration with progressive failure, but only use a linear solution in the region away from the stress concentration to reduce run time. If the same material is to be used for both regions, two different MATPFA entries must be issued within the Nastran model input file, each corresponding to a different material. Therefore you would need two different materials defined in the Materials Database with exactly the same properties and different IDs.

Recognizing a need for an approach which does not require you to recreate a material to accomplish the above scenario, the HIN file contains the capability to map one material ID to another using the keyword and data line shown below.

*MAP, FROM=ID, TO=ID

FROM, TOIn the above definition, the FROM and TO parameters on the second line allow you to map one material ID defined in the input file to another material ID defined in the input file. Using this method, you could specify two different materials in the analysis with different arguments and not have to recreate the base material of interest.

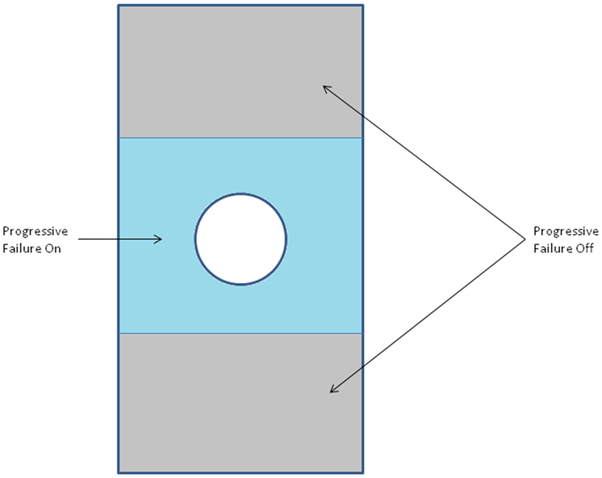

As an example, consider the open hole coupon shown below. Here, we want to deactivate progressive failure in the regions away from the stress concentration, which requires two different materials.

The only way to tell Nastran that different materials are to be used for the two regions is to create two material definitions and assign the materials to the two regions. When used with Helius PFA, each material would have corresponding MATPFA entry as shown below.

MATPFA, 1, 9001, 1, MCT, 0.10, 0.01, INSTANT, OFF

$

MATPFA, 2, 9002, 1, MCT, 0.10, 0.01, INSTANT, OFFNote, the only differences in the material definitions above are the material IDs and field 4 on the second line of the MATPFA entry. In general, any coefficient could be changed between the two materials. In a traditional analysis using Helius PFA, two different materials would have to be created and stored in the Materials Database to accommodate the scenario above. This means you would have multiple copies of a single material in the Materials Database, which is not desirable.

For this specific example, the card will appear as:

*MAP, FROM=ID, TO=ID

9002, 9001In the above, all of the static the material properties from material 9001 will be used for material 9002, while the fields (the dynamic material properties) for 9002 will be used as specified in the input file.