Interaction with Autodesk Inventor Nastran

In a Nastran structural-level finite element analysis of a composite structure, Helius PFA quickly and accurately decomposes the composite average stress/strain field into constituent average stress/strain fields. The constituent average stress states are used by Helius PFA to predict damage evolution and material failure individually for each constituent material in the microstructure. Subsequently, the current damaged microstructure is homogenized to provide an accurate assessment of the current composite average stiffness.

Helius PFA is designed to provide enhanced composite modeling capability without significantly increasing the time required to run the structural-level finite element analysis. Using it to enhance a structural-level finite element analysis usually increases the time required to perform a single structural-level equilibrium iteration by only two to three percent (a very small price to pay for the increased solution accuracy provided). Additionally, it is specifically developed to increase the convergence robustness of structural-level progressive failure simulations. Consequently, analyses enhanced by Helius PFA are more likely to successfully resolve the entire load history while using fewer total equilibrium iterations.

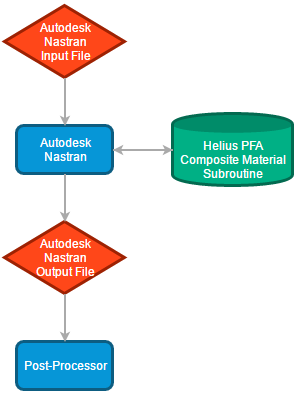

The image below shows a schematic of how Helius PFA interacts with the Nastran software components. Blue rectangles indicate components of Nastran (or other post-processors), red diamonds indicate files containing inputs and outputs, and green ovals indicate individual components of the Helius PFA software. Nastran communicates with Helius PFA to calculate the constitutive relations and compute stresses at each Gaussian integration point in the model where constitutive relations or stresses are requested. Nastran contains all of the MCT constitutive relations for the individual constituents (fiber and matrix) and the homogenized composite material. It also contains the constituent-based failure criteria and the nonlinear constituent damage algorithms. These degrade the stiffness of the constituents and the homogenized composite material to reflect the current damage state of the composite.

In the image below, the Composite Material Library stores all of the material coefficients needed to completely define the MCT multiscale material model. Before a particular composite material can be used in a Helius PFA-enhanced finite element model, it must undergo MCT material characterization, and a unique material file must be added to the Composite Material Library. As shown below, Nastran opens and reads the Composite Material Library to extract the necessary material coefficients for any composite materials used in the model. Note that material libraries are not necessary for Helius PFA cohesive materials. Since the number of inputs required to define a cohesive material are much less than a composite, the entire material is defined within the bulk data file.