To Add, Edit, or Sync a Sheet Metal Unfold Rule

Create and Name a Sheet Metal or Unfold Rules

Click Manage tab

Styles and Standards panel

Styles and Standards panel  Styles Editor

Styles Editor .

. In the Style and Standard Editor, click the plus sign to display the list of existing rules.

In the Style and Standard Editor, click the plus sign to display the list of existing rules.Click the Default rule to make it the template for the new rule.

Click New at the top right of the Style and Standard Editor.

In the Name field, replace Copy Of Default with a descriptive name for the rule and click OK. The New Style Name dialog closes, and a new rule is listed. The new rule is an exact copy of the Default rule.

Change values and settings as described below to add the new rule.

Note: If your file or library already contains rules, you can use any rule as the template for your new rule.

Define Sheet Metal Rules

In the Flat Pattern tab of the sheet metal rule, specify one or more of these values. Click Save when you finish.

- Material. Select or create one.

- Material thickness. Click the right-pointing arrow to select from previously defined thickness values.

- Sheet metal unfolding rule. Select an existing one or define a new one.

- Gap value of a miter, rip, or seam. Click the right-pointing arrow to select from previously defined gap values.

- Specify how to report the bend angle in the flat pattern.

- Display option for sheet metal punch iFeatures.

Specify Sheet Metal Bend Rules

In the Bend tab of the sheet metal rule, specify one or more of these values. Click Save when you finish.

- Bend relief shape.

- Bend relief. Typically, you use the Thickness parameter, but you can also specify an absolute size as required by your manufacturing practices. For example, the expression Thickness * 0.5 ul represents one-half of the Thickness parameter.

- Radius value. You generally use the Thickness parameter to specify the radius, but you can specify an absolute value.

- Bend transition type.

Define Sheet Metal Corner Rules

In the Corner tab of the sheet metal rule definition, specify one or more of these values. Click Save when you finish.

- Corner relief shape and size for 2-bend intersections.

- Corner relief shape and size for 3-bend intersections.

Define Sheet Metal Unfold Rules Using Linear Approximation

This method unfolds sheet metal part using a KFactor that is applied uniformly to all bend angles.

- For Unfold Method, select fx Linear.

- Enter a new KFactor value if needed.

- Adjust the Spline Factor value if needed (the default is 0.5). This value affects the flattened sizes of contour flanges, contour rolls, or lofted flanges with elliptical or spline segments in the feature profile. It also affects the length of noncylindrical or conical bends.

Define Sheet Metal Unfold Rules Using a Bend Table

This method unfolds sheet metal parts using empirical values that are measured or derived and applied to bend angles in the table. If angles are not defined in the table, values are calculated using a Backup KFactor.

- For Unfold Method, select Bend Table. The dialog now displays an environment in which to edit the sheet metal table.

- Specify values for the following, as needed:

- Linear units. Select from the drop-down list.

- Angle measurement. Select Outer or Open.

- Thickness. Select an existing one or add a new one.

- Backup KFactor.

- Spline Factor. This value affects the flattened sizes of contour flanges, contour rolls, or lofted flanges with elliptical or spline segments in the feature profile. It also affects the length of noncylindrical or conical bends.

- Table Tolerance. Supply values for Sheet, Min/Max Radii, or Min/Max Angle.

- If necessary, add rows for unspecified angle values.

- If necessary, add columns for unspecified bend radii.

- If necessary, edit table cells according to measured results for thicknesses, angles, radii, and shop equipment.

Define Sheet Metal Unfold Rules Using a Custom Equation

This method unfolds sheet metal parts using equations for bend compensation, bend deduction, bend allowance, or KFactor. Values for angles not defined within bounding conditions are calculated using a Backup KFactor.

- For Unfold Method, select Custom Equation. The dialog now displays an environment in which to edit custom equations.

- Specify values for the following, as needed:

- Equation Type. Select from the drop-down list.

- Angular Reference. Select Bending Angle or Open Angle.

- As needed, edit equations in cells. Double-click the cell to display the Edit dialog.

- As needed, select a bounding condition to to modify the bounding range. Double-click to display the Edit dialog.

- Delete unused rows if necessary.

- Specify values for the following, as needed:

- Backup KFactor. This value is applied when angular values conflict with bounding conditions.

- Spline Factor. This value affects the flattened sizes of contour flanges, contour rolls, or lofted flanges with elliptical or spline segments in the feature profile. It also affects the length of noncylindrical or conical bends.

Edit a Sheet Metal Rule or Unfold Rule

In the Style and Standard Editor, click the plus sign to display the list of existing rules.

In the Style and Standard Editor, click the plus sign to display the list of existing rules.- Click the rule to edit.

- Do one of the following:

- For sheet metal rules, change values and settings in the Sheet, Bend, and Corner tabs as needed.

- For sheet metal unfold rules, change the KFactor or bend table values as needed.

- Click Save.

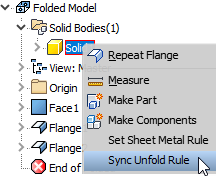

Sync a Sheet Metal Unfold Rule

This option provides a quick way to sync all features within a sheet metal body to share the same Unfold Rule.

Right-click a sheet metal body in the browser and select Sync Unfold Rule.

In the dialog box, select the desired sheet metal unfold rule to apply to all features and click OK.