Involute Spline Calculation Formulas in English Units

Transferred torque

![]()

where:

P | transferred power [lb ft] | |

n | speed [min -1 ] |

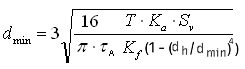

Minimum shaft diameter

shaft inside diameter d h > 0

a)

b) if d min ≤d h -> d min = 1.1 d h [in]

if else, the following formula is used to find the best diameter:

shaft inside diameter d h = 0

![]()

where:

d min | minimal shaft diameter [inm] | |

d h | shaft inside diameter [in] | |

T | torque [lb ft] | |

K a | application factor | |

K f | fatigue-life factor | |

S v | desired safety | |

τ Al | Allowable Shear Stress |

General calculation

Minimum splines length to transfer the torque

Fixed connection:

Flexible connection:

where:

Allowable pressure

1. Fixed connection:: |

|

2. Flexible connection: |

|

where: |

Strength Check

p min ≤ p Ds

p min ≤ p Dh

where:

p min | minimal calculated h/2 pressure [psi] | |

p Ds | allowable pressure in shaft [psi] | |

p Dh | allowable pressure in hub [psi] |

Shear stress under roots of external teeth

For a transmitted torque T, the torsional shear stress induced in the shaft under the root diameter of an external spline

For a solid shaft

![]()

For a hollow shaft

Shear stress at the pitch diameter of teeth

The shear stress at the pitch line of the teeth for a transmitted torque T

![]()

Calculated spline length:

L f = min {L, Le} [in]

Compressive stresses on sides of spline teeth

Allowable compressive stresses on splines are much lower than for gear teeth, since nonuniform load distribution and misalignment result in unequal load sharing and end loading of the teeth.

For flexible splines

![]()

For fixed splines

![]()

where:

Calculated spline length | L f = min {L, Le} [in] |

Depth of teeth engagement h h ≅ 0.9 / P [in] | for splines with flat groove bottom |

h ≅ 1 / P [in] | for splines with filleted groove bottom |

Bursting stresses on splines

Internal splines may burst due to tensile stress from the radial component of the transmitted load, centrifugal tensile stress, tensile stress due to the tangential force at the pitch line causing bending of the teeth.

1. Radial load tensile stress

![]()

where: Wall thickness of internal spline | t w = D oi - D ri [in] |

2. Centrifugal tensile stress | |

|

| |

3. Beam loading tensile stress | |

|

|

where: Calculated spline length | L f = min {L, L e } [in] |

4. The total tensile stress tending to burst the rim of the external member

![]()

Crowned splines for large misalignments

Crowned splines can accommodate misalignments of up to about 5 degrees. Crowned splines have considerably less capacity than straight splines of the same size if both are operating with precise alignment. However, when large misalignments exist, the crowned spline has greater capacity.

American Standard tooth forms may be used for crowned external members so that they may be mated with straight internal members of Standard form.

Compressive stress on the teeth

![]()

where:

Meaning of used variables