Single variate analysis method-stable warpage

If the part warpage is stable, meaning that the deflections of the part can be adequately predicted by a small deflection analysis assuming linear stress-strain behavior, the contribution of each constituent variate to the total deflection can be considered linear and additive.

If the part is not overconstrained, that is, the applied constraints only limit the rigid body motion without imposing forced deflections on the part, individual analyses are run for each effect which contributes to warp. In each case, the contribution of just one factor is taken into account.

If the part is overconstrained, meaning the constraints applied on the part will impose a forced deformation after the part is ejected, an additional individual analysis is run to determine the deflection contribution from the constraints. Notably, the contributions of differential shrinkage, differential cooling, orientation effects, and corner effect (if enabled in Midplane or Dual Domain analysis technologies), will be computed without the overconstraint effect. The contribution of the constraint effect is computed by subtracting the total deflection using automatic constraints from the total deflection using the manual constraints that the user has applied to the part.

Visual inspection of the magnitude of the part deflections in each single variate case indicates the dominant cause of warpage. This functionality is available for Midplane, Dual Domain, and 3D analysis technologies.

Differential Cooling Single Variate Analysis

This analysis calculates the shrinkage contribution due solely to differential cooling.

For the top and bottom of each element, and for the perpendicular and parallel directions, the differential cooling component of the shrinkage is determined by subtracting the differential shrinkage and orientation effects contributions from the total shrinkage determined from the shrinkage calculations as part of the Fill+Pack analysis.

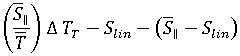

For example, for the parallel orientation direction of the top of the element, the contribution from cooling would be,

where

is the parallel shrinkage value from the packing analysis.

is the parallel shrinkage value from the packing analysis. is the difference between the temperature on the top of the element and room temperature.

is the difference between the temperature on the top of the element and room temperature. is the average of

is the average of  and

and

is the linear shrinkage value, as defined for the differential shrinkage variate.

is the linear shrinkage value, as defined for the differential shrinkage variate.

Differential Shrinkage Single Variate Analysis

This analysis calculates the shrinkage contribution due solely to differential shrinkage.

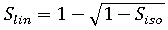

The shrinkage contribution due to orientation effects is eliminated by assigning to each element the same shrinkage value in both the parallel and perpendicular material orientation directions. This value is the linear shrinkage value  , given by:

, given by:

where  is the isotropic shrinkage determined in the shrinkage calculations as part of the Fill+Pack analysis.

is the isotropic shrinkage determined in the shrinkage calculations as part of the Fill+Pack analysis.

The contribution of differential cooling is eliminated by assigning this  value to both the top and the bottom of the element.

value to both the top and the bottom of the element.

Orientation Effects Single Variate Analysis

This analysis calculates the shrinkage contribution due solely to orientation effects.

The shrinkage contribution due to differential shrinkage is eliminated by subtracting the linear shrinkage value  , from the parallel and perpendicular shrinkage results determined in the shrinkage calculations as part of the Fill+Pack analysis.

, from the parallel and perpendicular shrinkage results determined in the shrinkage calculations as part of the Fill+Pack analysis.

The shrinkage contribution due to differential cooling is eliminated by assigning the same parallel and perpendicular shrinkage value to both the top and the bottom of the element.

Constraint Effects Single Variate Analysis

This analysis calculates the contribution due solely to constraint effects, which is computed by subtracting the total deflection using automatic constraints from the total deflection using the manual constraints that the user has applied to the part.