Microcellular foaming process

The microcellular process consists of four main, sequential steps, that end with solidification.

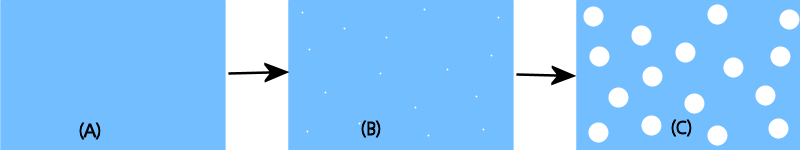

Figure 1: Microcellular foaming process, prior to solidification. (A) Single phase gas/polymer mixture, (B) bubble nucleation, (C) cell growth

The four main steps are:

Gas dissolution - In the plastication period of the microcellular injection molding process, a supercritical fluid (SCF) or blowing agent, nitrogen (N2) or carbon dioxide (CO2), is injected in to the polymer to form a single-phase solution. The gas is dissolved in the polymer melt due to applied high pressure.

Nucleation - this is the 'seeding' of bubbles and occurs as a result of a pressure drop. There are two types of processes, either short shot or full shot:

- Short-shot process - The mixture is injected into the mold cavity as a short shot to fill only part of the cavity. Due to the substantial and rapid pressure drop, the solution of the gas in the melt becomes supersaturated and a large number of bubbles nucleate.

- Full-short process - The mixture is injected to fill the mold cavity completely. After the cavity is volumetrically filled, it is pressurized and the nozzle is shut off. As the material within the cavity cools and then shrinks, bubbles nucleate due to the pressure falls.

Bubble growth - this is the increase in size of the bubble seeds as the gas diffuses out of the melt and into the bubbles.

Solidification - During the foaming process the mold is continuously cooled down, creating the internal cellular structure. The result is a foamed material with cell size of around 5-100 microns, the actual size depending on processing conditions. The lack of a formal packing phase reduces the residual stress in the material and results in extremely low warpage.