Simulate the process of relieving stress in parts and build plates after the processing model is complete. Enabling Simulate heat treatment in the dialog below automatically turns on Structural Plasticity on the Results tab of the Solver Settings dialog.

The Material stress relief temperature and Build plate stress relief temperature should be set to the temperatures at which stresses are relieved during heat treatment for each material. The field for entering a separate build plate annealing temperature is available only if the build plate is a different material from the part.

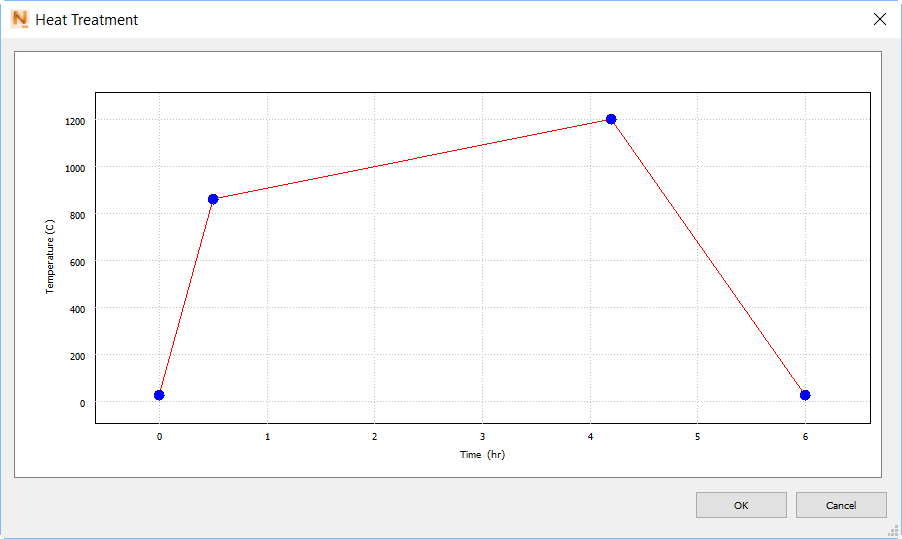

Specify the temperature and time curve for the stress relaxation process in the Heat treatment process table. Use the Add Row and Delete Row buttons to create the required number of oven temperature set points, and to correct any errors. The number of hours to maintain a particular temperature indicates the elapsed time from the beginning of heat treatment to the end of that temperature set point, so each time value is longer than its predecessor. The system checks to ensure that minimum of two time-temperature pairs are specified and that all entries are in time-ascending order.

The Show Plot button displays a temperature-over-time plot of the specified heat treatment process:

The Cancel button resets time and temperature values to 0 and closes the dialog, so it's useful if you want to recover from an error, or change all the table values.