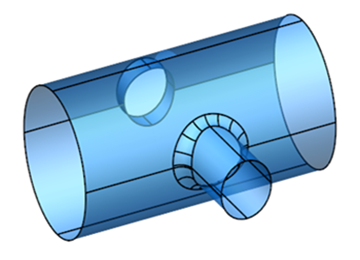

A fillet is the rounding of an interior or exterior corner that is formed by the intersection of two surfaces. PowerShape can produce a constant-radius fillet surface between any pair of surfaces which intersect.

A typical fillet surface between two intersecting surfaces.

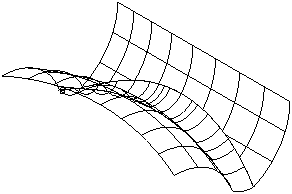

You can produce a fillet when two surfaces do not intersect. The only condition is that, if offset by the fillet radius, they would intersect:

Where two surfaces are divergent, the fillet is produced between the portions of the surfaces that do intersect when offset by the fillet radius:

Other fillets of this type are shown below:

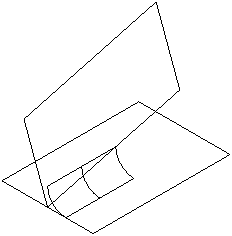

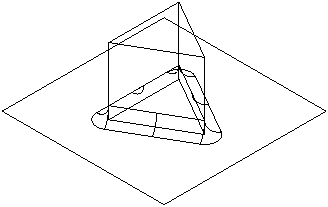

If the intersection line between surfaces contains discontinuities (for example, as a result of sharp corners, or because some of the inside radii are smaller than the fillet's radius), PowerShape constructs a series of fillets from the unbroken portions of line. For example, the fillet below incorporates six separate fillet surfaces, one for each corner and one for each side, to create a single fillet surface:

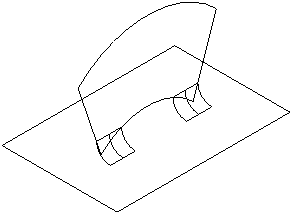

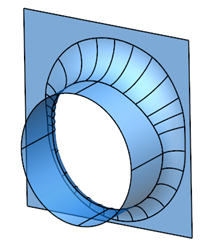

A variable radius fillet may be created with different radius values at specified points:

As you can see the variable fillet is used to good effect here. A constant fillet would only have allowed the smallest radius to be used along the whole length of the fillet, but here we specified a larger radius on one side to improve strength and avoid run-out of the fillet on the narrower side.