Nitinol Material Property Definition

Description: Defines material properties for use in shape memory alloys (Nitinol).

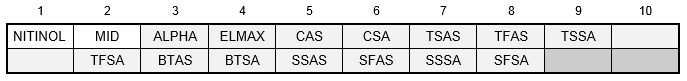

Format:

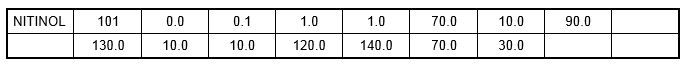

Example:

| Field | Definition | Type | Default |

|---|---|---|---|

| MID | Identification number of a MAT1 entry. | Integer > 0 | Required |

| ALPHA | Pressure coefficient. | Real ≥ 0 | 0.1 |

| ELMAX | Maximum residual strain. | Real ≥ 0 | 0.1 |

| CAS | Conversion constant from austenite to martensite. | Real ≥ 0 | 1.0 |

| CSA | Conversion constant from martensite to austenite. | Real ≥ 0 | 1.0 |

| TSAS | Starting temperature of transformation from austenite to martensite. | Real | 0.0 See Remark 1 |

| TFAS | Ending temperature of transformation from austenite to martensite. | Real | 0.0 See Remark 1 |

| TSSA | Starting temperature of transformation from martensite to austenite. | Real | 0.0 See Remark 1 |

| TFSA | Ending temperature of transformation from martensite to austenite. | Real | 0.0 See Remark 1 |

| BTAS | Constant for exponential flow rule (austenite to martensite). | Real ≥ 0 | 0.0 See Remark 2 |

| BTSA | Constant for exponential flow rule (martensite to austenite). | Real ≥ 0 | 0.0 See Remark 2 |

| SSAS | Starting stress for transformation from austenite to martensite at reference temperature. | Real | 0.0 See Remark 3 |

| SFAS | Ending stress for transformation from austenite to martensite at reference temperature. | Real | 0.0 See Remark 3 |

| SSSA | Starting stress for transformation from martensite to austenite at reference temperature. | Real | 0.0 See Remark 3 |

| SFSA | Ending stress for transformation from martensite to austenite at reference temperature. | Real | 0.0 See Remark 3 |

Remarks:

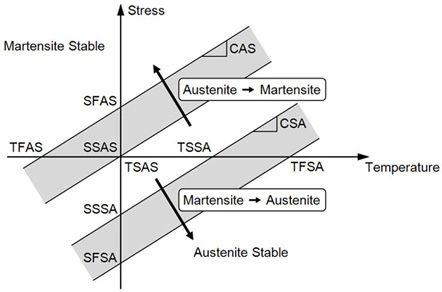

- The following relations must be satisfied between the four temperatures:

TFAS < TSAS < TSSA < TFSA

- When BTAS and BTSA are zero the material model is linear. When BTAS and BTSA are non-zero the material model is exponential with BTAS and BTSA as coefficients.

- The transformation stresses and temperature can be combined such that the transformation stress can be calculated by

- Starting stress for transformation from austenite to martensite = SSAS - CAS*TSAS

- Ending stress for transformation from austenite to martensite = SFAS - CAS*TFAS

- Starting stress for transformation from martensite to austenite = SSSA - CSA*TSSA

- Ending stress for transformation from martensite to austenite = SFSA - CSA*TFSA

Figure 1. Stress-Temperature Transformation Variables