Sheet Metal Contour Roll Reference

Access

Ribbon: Sheet Metal tab  Create panel

Create panel  Contour Roll

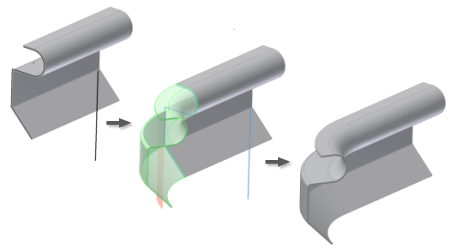

Contour Roll

Shape

Selects profile geometry.

Selects the rotation axis. Rotation axis geometry must be contained within the sketch containing the profile geometry.

Flip Side  or

or

Click to offset the material thickness to the other side of the selected profile.

Both Sides

Both Sides

Click to offset the material thickness equally to both sides of the selected profile.

Rolled Angle

Specifies the value of the angular sweep of the rolled section. Defaults to 90 degrees. Angle value cannot equal 360 degrees for multi-segment profiles. You can use a rolled angle value of 360 degrees for profiles with a single, straight line.

or

or

When active, click to sweep the Contour Roll in the direction opposite of the previewed direction.

![]()

Click to sweep the Contour Roll equally both clockwise and counter-clockwise from the selected profile.

Unfolding Unrolling

Specifies the method to unroll the Contour Roll feature. These methods all derive a Developed Length by multiplying the Rolled Angle by a Neutral Radius. They differ by the type of input provided:

Unroll Method

Centroid Cylinder

An axis parallel to the revolute axis passes through the evaluated Centroid location providing input to define a neutral cylindrical surface. Default method.

Custom Cylinder

Specifies a sketched line that defines the surface of the cylindrical neutral surface.

Developed Length

Specifies the value that drives the developed length of the flattened rolled segment.

Neutral Radius

Parametrically determines a value for the neutral radius (when multi-segment profiles are considered).

KFactor

Method used for single-segment linear profiles.

Unfold Rule

Specifies an Unfold Rule that differs from the Unfold Rule specified in the active Sheet Metal Rule. Selection is from a drop-down list.

Neutral Radius

Displays the value of the neutral radius used when deriving a developed length using a rolled angle.

Unrolled Length

Informational display. Displays the length value of the unrolled Contour Roll feature.

Bend Radius

Specifies the value for the bend radius. Defaults to the system parameter BendRadius. Disabled when a single, linear profile is selected.