Calculating V-Belt Strength Proportions

General equations used

|

|

|

Where m is a specific mass of belt defined as m = S ρ |

Modified friction factor of given pulley

|

|

|

|

| f = f g + v f mod |

Driver pulley and belt fundamental equations

power to transmit

![]()

Belt speed

![]()

Belt flexing frequency

![]()

Effective pull (or effective tension)

![]()

Centrifugal force

Fc = z m v 2

Tension in belt spans

In the following equations, the application first determines the most suspicious pulley what requires the maximum belt installation tension to transmit a load. Then the belt tension in each span is adjusted for all pulleys accordingly with respect to initial belt installation tension.

|

|

|

F 1i - F p P xi - F 2i = 0 | |

|

| |

|

|

The most suspicious pulley criteria is maximum tight side tension

F 1max = max (F 1i )

The total maximum tension in belt span (per belt) when the belt drive is under full load is determined as

![]()

Where expression “k 1 F 1max ” is the actual maximum tension in belt span considered for all belts in the belt drive. In this manner, all corresponding tensions in individual spans are re-computed to fulfill following condition:

F 1i - F P P xi - F 2i = 0

Resultant axle load for each pulley when the belt drive is under full load

![]()

![]()

Belt initial installation tension and static tensioning force

The required belt initial installation tension (per belt) can be adjusted by tensioning factor and then determined as follows:

![]()

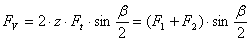

Static tensioning force F v is determined for each pulley. The application computes the tensioning force that performs along the centerline of belt spans as follows:

|

|

|

Meaning of used variables: