3.7 Stresses At Transfer of a Pre-Stress Section

Subjects Covered

- Prestress Tendons

- Relaxation loss

- Elastic Loss

- Interpolated/short term Modulus

- User Notes

- Stress/Strain calculation Reports

- Inverted Neutral Axis for Hogging

Outline

The pre stressed section defined in Section 2 is opened and the slab and edge section are removed from the section definition.

The section represents the mid span section of a 25m long beam which has been cast and stressed and is about to be released from its mould. The concrete strength at this stage is based on grade C32/40 concrete and the relaxation loss in the tendon force is assumed to be 1.25%. The self weight moment is calculated based upon a weight density of 24kN/m³ and applied in the load table. (Note however that a density of 25kN/m³ is used for some other examples in the manual to allow for the additional 1kN/m³ due to the tendons). An SLS stress analysis is carried out assuming that the neutral axis remains horizontal, and the elastic modulus is set to the short term modulus.

The stress results are the stresses in the concrete taking into account the losses in the tendons due to the elastic deformation of the concrete. By temporarily setting the elastic modulus of the concrete to a very high value (say 10000kN/mm²) the resulting stresses are those without elastic deformation losses.

Procedure

- Start the program and use the Home Open button to open the file “My EU Example 2_7.sam” created in example 2.7.

- Use the menu item File | Titles to change the Section Title to “Prestressed Section Analysis”, the Sub-title to “Example 3.7” and the Job Number to “3.7”. Click ✓ OK to close the Titles form.

- In the Design Section navigation window select the “Slab” element from the navigation tree and then use the - button in the toolbar to delete this element.

- Repeat this for the “Edge Detail” element so that it just leaves the “YE3 Beam”.

- Select the “YE3 Beam element from the navigation tree and assign the Grade C32/40 concrete by using the drop down selection of the Property field. Click the ✓ OK button to close the Define Section Element form.

- To find the cross-sectional area of the beam, use the “Analyse” button dropdown to select “Section Properties” to open the Calculate Section Properties form.

| Analyze | Section Properties |

|---|---|

|

|

The cross-sectional area is 0.522m². If we assume that the weight density is 24kN/m³ and the length of the beam is 25m, then an My bending moment of 978.75kNm (i.e 0.522×24×25x25/8) must be applied to the beam.

Click the ✓ OK button to close the Calculate Section Properties form.

Open the Define Loadcase data form using the button in the navigation window toolbar, and select Loadcase.

Click on the + button near the bottom of the form to add a row to the table. In this added row select “Y Moment” from the Type drop down list and enter a value of “978.75kNm” in the Characteristic Effect column. Also, set the Permanent/Variable field to “Perm”.

In the data at the top part of the form set the Combination to “SLS Characteristic” and change the loadcase name to “Loadcase 1”.

Click on the ✓ OK button to close the Define Loadcase form.

The relaxation loss in the tendon force must be accounted for before analyzing. Open the Define Tendons form selecting “Tendons” in the navigation tree.

The tendon forces are 241kN and must be reduced by 1.25%. Click on the “Edit Tendons” button. Window around the whole section in the graphics window to select all of the tendons. This will open the Edit Tendons sub form. On the sub form set the Edit Option field to “Change force” and enter a value of “238kN” in the Tendon Force field. Click ✓ OK on the sub form.

Click the ✓ OK button to close the Define Tendons form.

It is useful to make a note of this in the User Notes form which can be opened up by right mouse clicking anywhere in the navigation window and selecting “Notes...” Enter the following text “Tendon forces have been reduced from 241kN to 238kN to represent relaxation losses at transfer.” Then close the form with the ✓ OK button.

Now use the

button dropdown to select “Bending Axial and Shear” to open the Bending Axial and shear analysis form and dismiss the error message.

button dropdown to select “Bending Axial and Shear” to open the Bending Axial and shear analysis form and dismiss the error message.Ensure that Analysis type is set to “SLS Characteristic." Click on the Neutral Axis angle drop down and select “Set angle to” from the list. Click in the corresponding edit box and enter a value of “180°”. (This is necessary as the bottom of the beam is more compressive than the top).

By default the elastic modulus used in the calculations will be interpolated between the long and short term values and as the load is totally “Permanent” the modulus will be equal to the long term value. To force the short term value to be used we use the Set Parameter for: field to “Serviceability Calculations” and in the displayed sub-form set Elastic Modulus Type: to “Short Term”. Close the sub-form with the ✓ OK button.

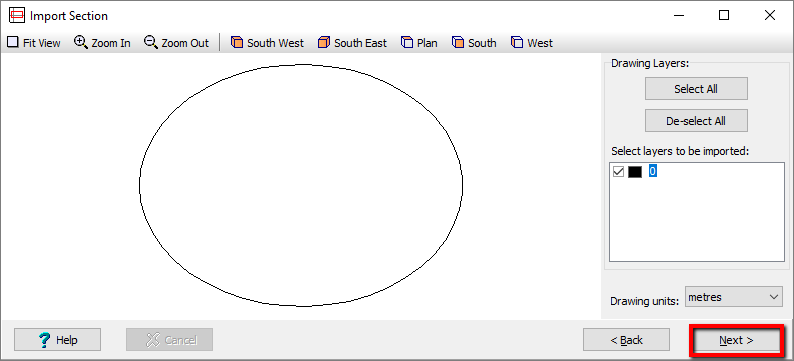

The iterations now converge and the graphic display is shown as:

Click on the Results button to display the Results Viewer.

The maximum stress in the tendons is -1211.117N/mm². The minimum stress is -1286.991N/mm².

The full stress in the tendon should be the tendon force divided by the tendon area = 238000/181 = 1314.9N/mm². The difference in these values is due to elastic deformation losses.

Close the results viewer and then click on the ✓ OK button to close the Bending, Axial and Shear form.

Change to the Materials navigation window and select the Grade C32/40 concrete in the navigation tree. On the Define Property Details form, click in the_ Modulus of Elasticity_ field and enter a value of 10000GPa. The program will display a warning message saying “Outside expected range”. Click on the ✓ OK button.

Close the Define Property Details form with ✓ OK and then change to the Design Section navigation window.

Click on the

Analyse toolbar button in the navigation widow to open the Bending, Axial and Shear form. Click ✓ OK on the Error message (note that the section is over-stressed – this would obviously require action, but for this example we will ignore it) and then click on the Results button to display the Results Viewer.

Analyse toolbar button in the navigation widow to open the Bending, Axial and Shear form. Click ✓ OK on the Error message (note that the section is over-stressed – this would obviously require action, but for this example we will ignore it) and then click on the Results button to display the Results Viewer.

The maximum and minimum stresses without elastic deformation losses are now -1314.526N/mm² and -1314.836N/mm² respectively.

Close the Results Viewer and click on the ✓ OK button to close the Bending, Axial and Shear form.

Change the material back to default grade C32/40 concrete by opening the Define Material Properties form, clicking on the grade C32/40 concrete and then clicking on the “Default” button on the Define Property Details form.

Confirm that you want to reset to default values by clicking on “Yes” on the form that appears.

Now enter a cube strength value of “40” and press the “enter” key.

Close the material form with the ✓ OK button.

Save the data file to “My EU Example 3_7.sam” using the menu item *File | Save As... *

Close the program.

Summary

This example demonstrates the effect of including prestress tendons in a section.

The resultant stresses are due to the prestress force and the moments from the dead weight of the beam. If it was required to see the stresses from the prestress only, then a very small dead load could be applied.

It should be noted that although relaxation losses are included in the material form for pre-stressing tendons, this data is not used as the section analysis is not fixed to a given time. This is why the tendon forces were modified manually to set the relaxation loss to 1.25%.

The stress diagrams are always produced with compressive forces at the top. If a hogging moment is applied to a section it automatically inverts the section. In the prestress case the applied moment is sagging but the prestress provides higher compressive stress at the bottom of the beam. This is why the neutral axis needed to be inverted manually.