To create a stiffener within the Fittings section of the database:

- Click Database

Fittings

Fittings

Specification

Specification

Stiffeners.

Stiffeners.

- Click the Manufacturing button

located along the top of the dialog, and then click New

located along the top of the dialog, and then click New

.

.

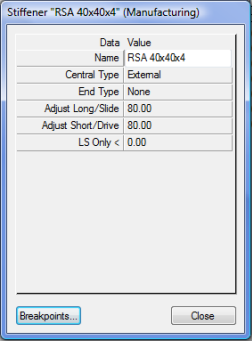

- On the new Stiffener dialog, specify a name for this stiffener.

For each stiffener created, you can specify whether the stiffener is to be used for internal, external or both types of stiffening. Additional options specify whether each type of stiffener will be positioned at the center of the duct or at each end.

- Specify the Central Type of the stiffener: internal or external, and the end type.

If the Central Type is External, specify whether to apply additional adjustments on the long and short sides, or whether Long Side only stiffening is to be used.

Central Type/End Type: Using the drop-down for Central Type and End Type specifies where the stiffeners are to be positioned. Setting this option to None results in no stiffener being present for that type.

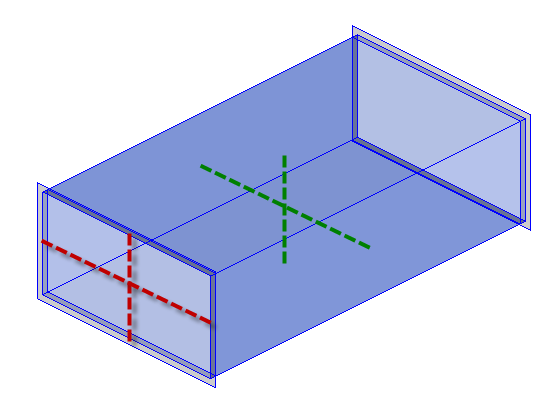

External type: This is used primarily for flange type stiffeners that will calculate lengths of stiffener, based on the periphery of the duct. Example stiffener types are shown below. Central type is shown in green, and end type is shown in red.

Internal type: This is used for internally stiffening with tie rods and can be used to specify hole placements for the tie rods when manufacturing. The software can additionally cut these holes when the stiffener is applied to the duct at takeoff. Tie rods shown in green are Internal Central type, and red are End type internal tie rods.

Both: Both external flange type and internal tie rods can be specified to be used either centrally or at the end of the duct, dependant on application of each type via the breakpoints. See Create Stiffener Breakpoints for instructions on how to configure this.

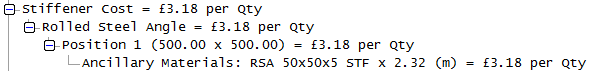

Adjust Long/Short Slide/Drive: Adjustments can be made to the Long and Short sides of the stiffener for example a 500x500 duct would require a slightly larger External stiffener to wrap round the periphery of the duct. Setting the Adjust fields to 80mm each on Long and Short sides will result in your total stiffener length being 2.32m ((4 x 500mm) + (4 x 80mm)).

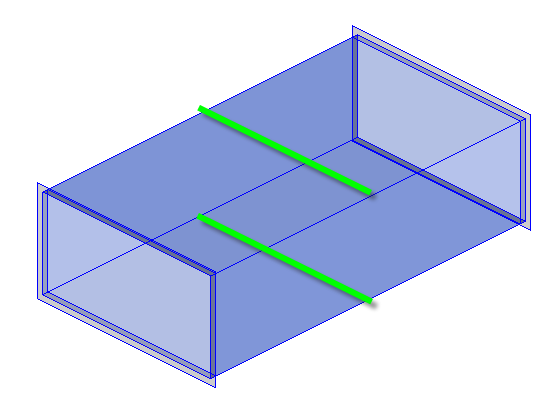

LS Only: This parameter can be set if only wanting to calculate the total length of stiffener based on the largest side. This option for example if set with a value of 500mm and the duct size for the stiffener application is 800x400, will result in the short side (400mm) being taken out of the calculation for the total length. The result being 2 x 800mm stiffeners equalling 1.6m total length ignoring any adjustments in this case.

An external stiffener used with the LS Only option is shown above in green.

-

You can add breakpoints for each of the various stiffener quantities or scenarios by selecting the Breakpoints

button at the bottom of the dialog when editing the Stiffener.

button at the bottom of the dialog when editing the Stiffener.

If internally stiffening, Length and Span breakpoints are required to be configured, which dictates the quantity and type of tie rods to be used. To configure length and span breakpoints, click

.

.

If externally stiffened, the ancillary types to be used on the External breakpoint dialog must be specified. This ensures costs are calculated based on the entries made for each dimension breakpoint. To specify this, click Show External Breakpoints

.

.

For more information, see Create Stiffener Breakpoints.

- When the stiffener creation is complete, the stiffener can be directly applied to the duct, or it can be applied by using a specification to automatically assign at takeoff. See Specifications for information on how to assign stiffeners to a Specification.