This Help topic describes how the Autodesk Fabrication products can provide a complete workflow, and can track products from the drawing office or order processing departments, all the way through to manufacturing and delivery.

Workflow

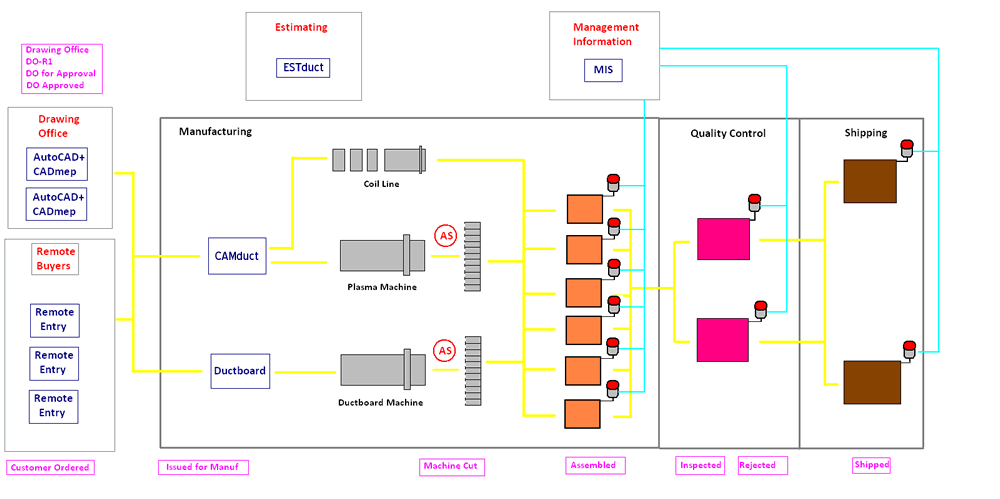

The diagram shows a typical factory layout for manufacturing both metal and insulated board ductwork. If round duct is applicable, the tube former would be added into the process.

Typically, the main CNC machines used for manufacturing are:

- A coil line for manufacturing straight duct.

- A plasma profiling machine to cut metal fittings.

- A routing machine that uses either routing tools or tangential knives for cutting insulated board (ductboard).

The input of jobs for the manufacturing department can originate from:

- Remote agents, customers, site operatives using the Autodesk Fabrication RemoteEntry software.

- Automatically from the drawing offices using Autodesk Fabrication CADmep software.

- Takeoff from approved paper drawings through our Autodesk Fabrication CAMduct software.

Estimating could also be involved in this process for the costing side using Autodesk Fabrication ESTmep.

Because ductwork for several projects may be processed simultaneously, it can be challenging to quickly understand and visualize the percentage complete for each project. It is important to have a complete audit trail of the items passing through each system. This can be achieved by using the following features available in the Autodesk Fabrication products: Item Statuses, Bar Coded or QR Code labels for parts being produced, and then using Status checking.