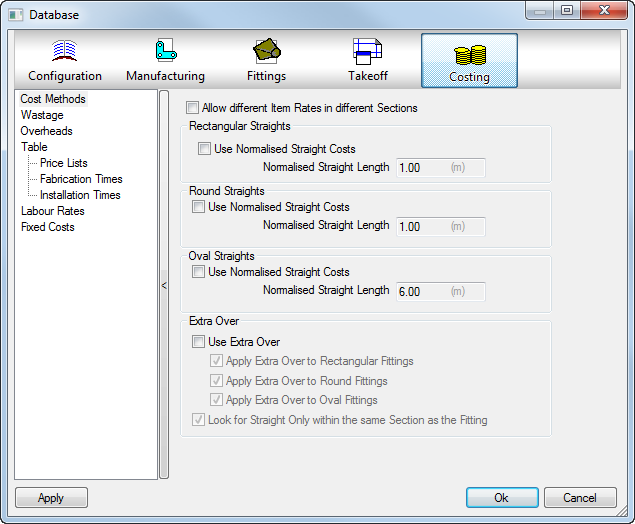

The Cost Methods settings are used to determine the calculation of item rates. The settings are accessed by clicking the Database

Costing

Costing

Cost Methods option.

Cost Methods option.

Normalisation Straight Costs

With the Use Normalised Straight Costs option enabled, entering a value here should be the value that you require the calculation to be based upon.

For example, 3.00 meters entered here would accommodate for most ancillary spacing, using multiple frames across the 3.00 length (4 if 1500 standard straights), supports, stiffeners etc. Therefore, when divided to result in the per meter cost, the rate per meter will contain a percentage of these ancillaries, along with material, fabrication and installation averages. This produces a standard cost per/m throughout the job.

To determine how to best configure your normalisation of straights when using flanges (CGF, TDF,TDC), as this requires additional material, it is generally recommended to use 2 or 3 times your finished length to be specified in these fields.

The following is a guide on how to configure connectors and straights to produce the desired dimensions and costing values for your projects.

STD Straight option in the Specification

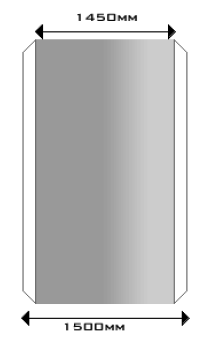

This is the complete length, including connector allowances, which is also known as the development length or coil width. Finished length will be a factor of the 'STD Straight Length' with the final length being adjusted for the connector type in use.

For example, a 1500 auto length entered, which has a sheet metal flange applied of 25mm to each end, the display object will show 1450mm as the finished length.

Within Job contents or Quick Takeoff view, using the Qty/Length field as the display will report the length minus the connector allowance applied.

For example: Setting up the costing of this must be using the following method:

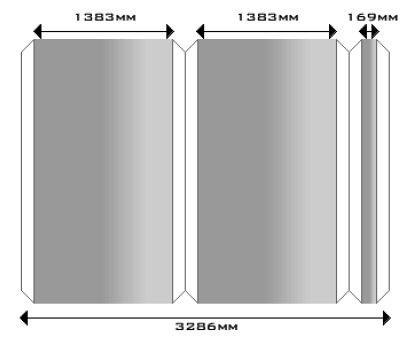

The Normalised length from within Costing Database = this is usually double the finished straight length. If we use the above again as the example data, the length to input here would be 1.45m, 2.9m, 4.35m. There is also the consideration of support and stiffener spacing, as Normalised lengths above the active spec spacing would provide a more accurate cost per meter, as these include support/stiffener ancillaries.

For example, spacing for each of these at 3m (within the Specification table) would not be taken into consideration for the 1.45m and the 2.9m finished lengths. Only the 4.35m length (x3 of the finished length) would incorporate the cost for supports and stiffeners effectively.

The diagram below is an example of what could happen if the normalisation field does not have a sufficient value which is not a multiple of the finished length. This would cause additional material and additional connectors would then be assigned generating excessive cost.

For best results, we strongly recommend testing a number of scenarios until happy with the costs being generated.

Extra Over

Extra Over is an alternate estimating method that is used for speed rather than accuracy. It is primarily used by estimators who have a single line drawing or use a digitizer.

When Extra Over is enabled, straight duct is measured 'through' the fittings to its center point without fittings. The resulting measurement provides additional straight duct. The extra duct is accounted for when fittings are added and the centerline length of each fitting is calculated. The cost of the equivalent length of straight duct is calculated and subtracted from the cost of the fittings.

The Extra Over method should be set only at the start of each quotation. The Extra Over method can also be enabled or disabled from the Takeoff menu in Quick Takeoff.