Most ductwork manufacturers have to work to a specification. A specification is generally a set of rules that govern how ductwork is made and installed. Setting up a specification correctly in the Fabrication products allows certain information about the part to be specified automatically, instead of having to specify these factors individually, for each part.

Setting up the specifications enables the automatic selection of parameters. Some patterns have the ability to override the Specification settings. It is not essential for ductwork users to set up or use specifications. However, when the specification table is correctly set up, it makes adding items to a job considerably easier and quicker. It is necessary to set up Connector and Seam parameters before defining specifications.

The Specification Properties can be accessed by clicking the Properties icon

on the Database

on the Database

Fittings

Fittings

Specifications dialog.

Specifications dialog.

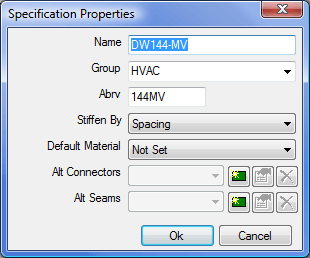

The Specification Properties are described below.

Name: The descriptive name given to identify the specification.

Group: Specifications can be grouped together into separate Groups, to create a new Group type the name in this box. Specifications can then be moved to other Groups by selecting the group from the drop-down box.

Abrv: An abbreviated name used in identifying the specification and on Reports.

Stiffen By: This allows the specification to set the number of Stiffeners used on an item to be determined by Spacing or by an Input Value.

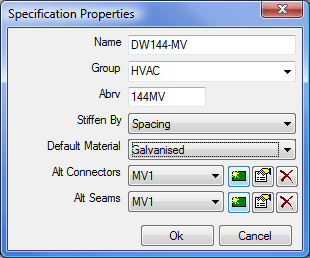

Default Material: The material picked up by default when using this specification in Takeoff.

Alt Connectors: The Alt Connector allows the user to allocate a different set of Connector Information to an item file where you still want the item to follow the rest of the Specification Parameters.

Alt Seams: The Alt Seams allows the user to allocate a different set of Seam information to an item where you still want the item to follow the rest of the Specification Parameters

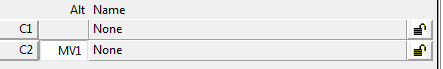

Selecting the New icon in Alt Connectors or Seams will let the user enter a name for the Alternative Field. This will then be displayed in the Specification Table as an Alternative Connector and/or Seam.

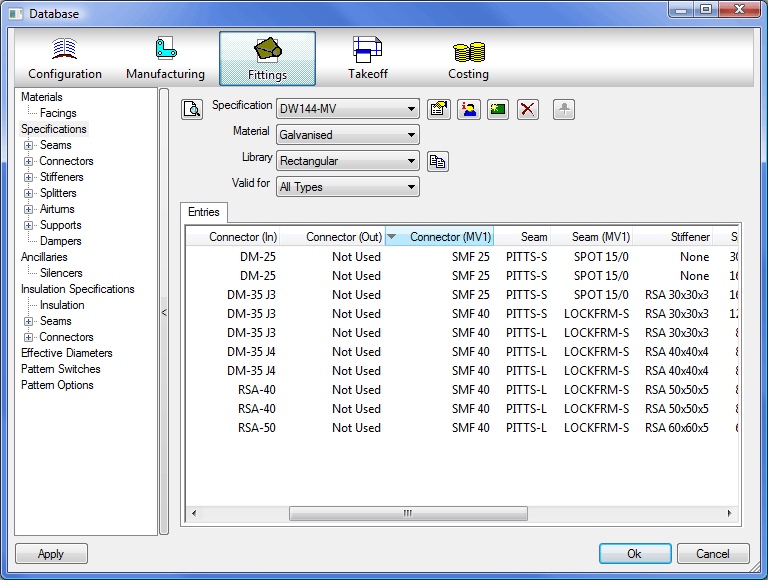

In the example above, an Alt Connector and Seam were created called MV1. This then creates the extra columns in the specification table.

The item file has to be edited and the Alternative Connector and/or Seam name is entered into the Alt column.

This applies the normal specification entry to the item as well as the Alternative Entry.

Modifying Specifications

To modify a specification:

- Double-click an entry to edit the details.

- To create a new entry in the specification, right-click on the table and click New.

<= Dim: The figure input here will specify that a fitting with a Longest Side value of up to and including that figure will use the factors set here.

Gauge: This specifies what gauge the material will be.

STD Straight: Specifies the standard straight length

Connector (In): Specifies the type of connector used.

Connector (Out): Specifies the type of connector used.

Seam: Specifies the type of seam applied to the fitting.

Stiffener: Specifies the type of stiffener applied to the fitting.

Spacing: Specifies the break points for the placing of the stiffeners.

Supports: Specifies the type of supports for this fitting.

Spacing: Specifies the break points for the placing of the supports.

Sealant (Rectangular Patterns Only): Specifies the type of sealant applied.

Splitter (Rectangular Patterns Only): Specifies the type of splitter applied to the item.

Airturn (Rectangular Patterns Only): Specifies the type of airturn applied to the item.

Collar (Round, Flat Oval, and Standard Only) : Specifies the collar type applied to the item.

Damper (Round, Flat Oval, and Standard Only): Specifies the damper type applied to the item.

Pipe OD: Used in CADmep. Pipe outside diameter.

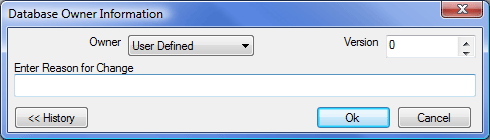

Displaying Owner Information

Click the Owner Information icon

to display details on who created the specification and any revision changes that may have been made.

to display details on who created the specification and any revision changes that may have been made.

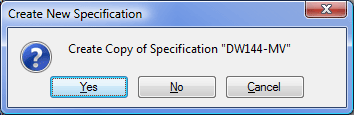

Creating a New Specification

To create a new specification:

- Click the New

icon.

icon.

- A dialog displays asking if you want to create a copy of an Existing Specification. This can speed up the entry of information if the Breakpoints are similar to the currently open specification.

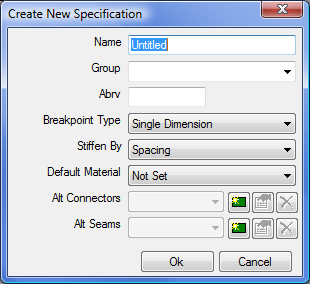

- If Yes is selected then the software will create a copy of the specification for the user to edit. If No is selected, the Create New Specification dialog displays.

Name: Gives the specification a descriptive name.

Group: This option enables you to create groups and add specifications to existing groups.

Abrv: Here you can give the specification an abbreviated title for use in Reports

Breakpoint Type: There are 4 options to specify the Breakpoint type.

- Single Dimension.

- LS / SS Dimensions.

- Single Dimension + Length.

- LS / SS Dimensions + Length.

The type of breakpoint used will determine what criteria the specification will look for before applying the breakpoints.

Single Dimension

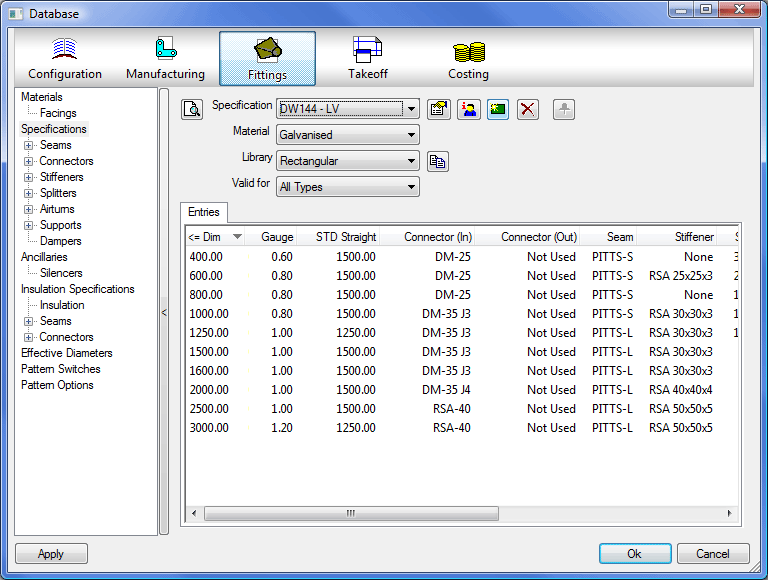

This specification will look for the longest side of the duct to determine what values to apply to the pattern. The figures in the less than or equal to Dimension field will create the breakpoints.

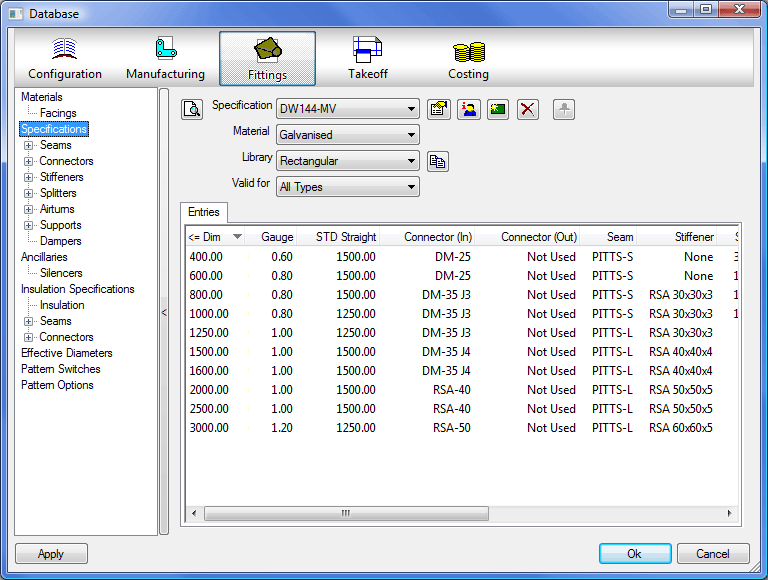

In the example above, a Single Dimension specification with an item of duct where the longest side dimension that is less than or equal to( <= ) 400mm will apply 0.60 Gauge Galvanised, a DM-25 Connector, PITTS-S Seam, and No Stiffener to the duct. Whereas a duct with its longest side less than or equal to 600mm, but greater than 400mm, will be applied 0.80 Gauge Galvanised, DM-25 Connectors and a PITTS-S Seam and a DM-25 Stiffener.

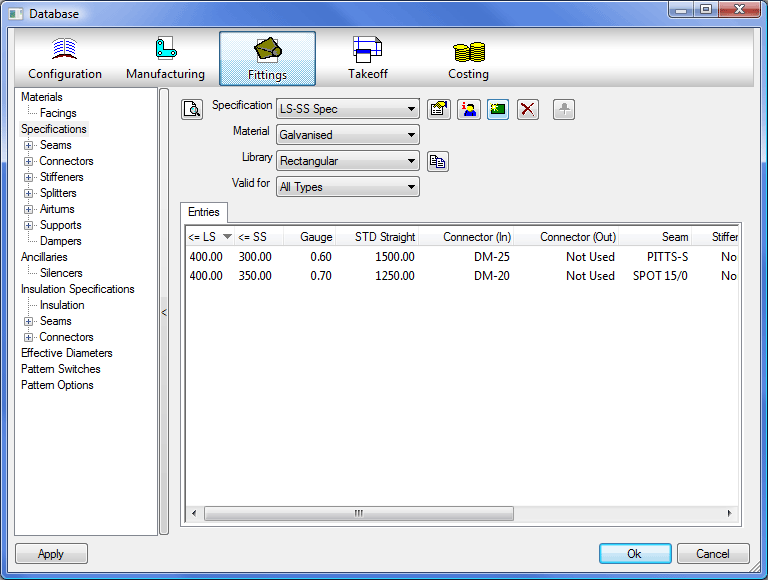

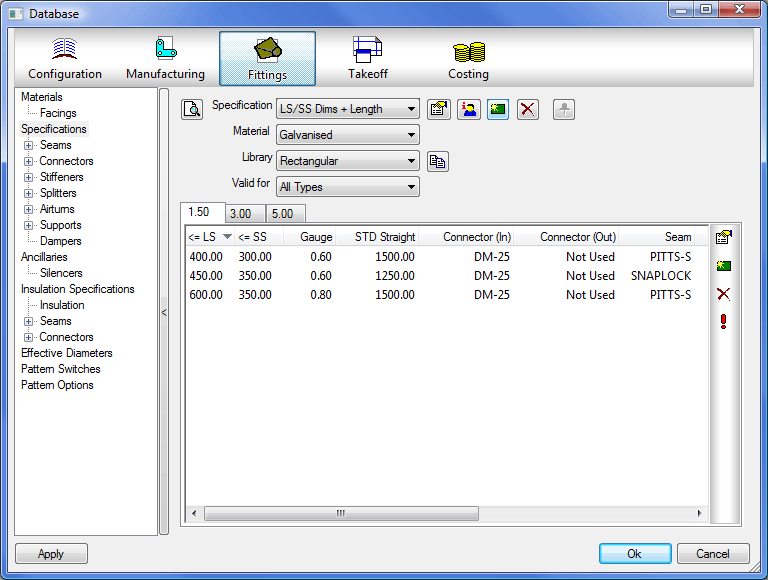

LS/SS (Longest Side, Shortest Side) Dimension

This specification looks to the longest side and the shortest side of the duct to determine what criteria are applied to the duct.

For example, in the table above, a duct with a long side of equal or less than 400mm and a short side of equal or less than 300mm would be applied 0.60 gauge Galvanised, DM-25 connectors, and a PITTS-S seam. Whereas a duct with a long side of 400mm and a short side of less than or equal to 350mm but greater than 300mm would be assigned 0.70 gauge Galvanised, DM-25 Connectors, and a SPOT 15/0 seam.

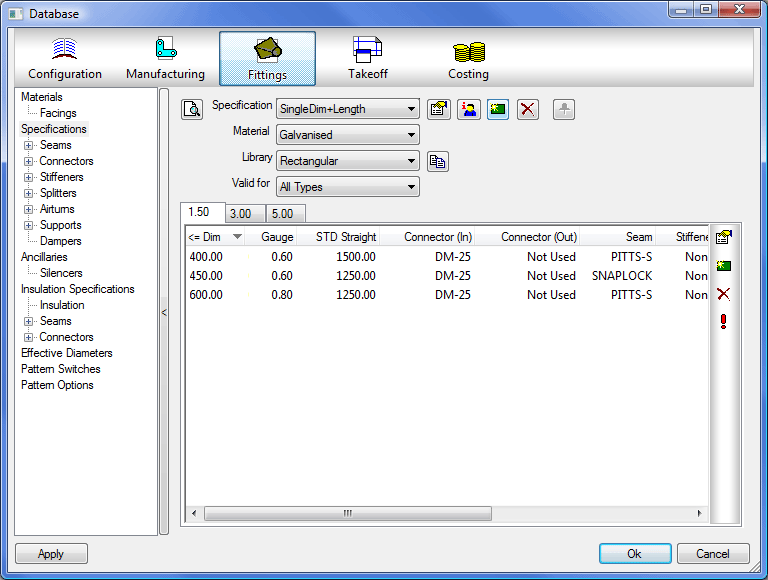

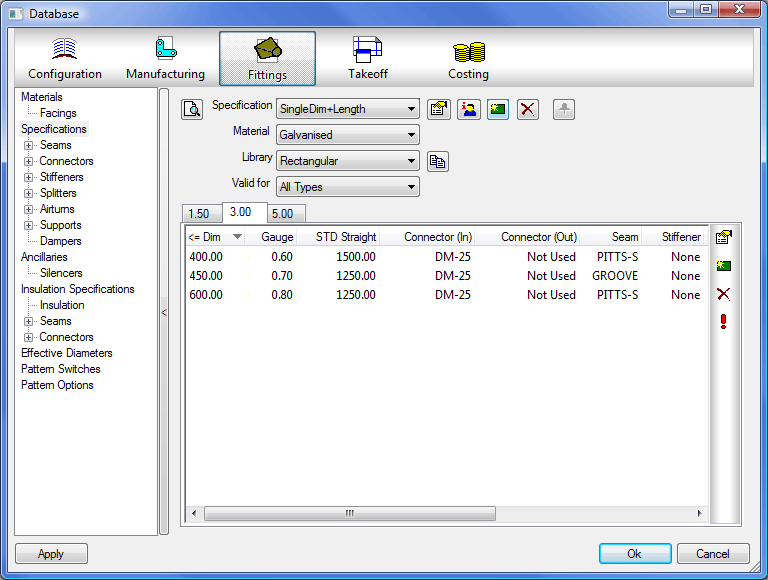

Single Dimension Plus Length

This specification is similar in some respects to the LS/SS specification, but this one looks for the longest dimension in the Width and Height field and looks at the length of the duct to create further breakpoints. The length breakpoints are input by creating new tables in tabs.

A new tab is created by clicking on the green New icon

. An existing tab length can be edited by clicking on the Edit Length icon

. An existing tab length can be edited by clicking on the Edit Length icon

.

.

In the example above, a duct with a long side of 450mm and a length of 1.5m or less is allocates 0.60 gauge galvanised, DM-25 connectors and a SNAPLOCK seam. Whereas in the table below, the same duct but with a length of 3m will allocate it 0.70 gauge galvanised, DM-25 connectors, and a GROOVE seam.

LS / SS Dimensions Plus Length

This specification will look at all dimensions on the duct and apply the criteria accordingly. It is setup the same way as LS Dimensions + Length, but with the added Short Side dimension.

For information on how to change the specification assigned to an item, see Changing the Specification.