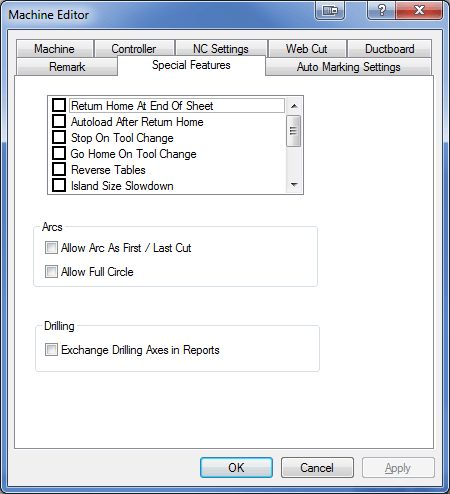

On the Machine Editor dialog, the settings on the Special Features tab determine certain low-level machine operations that should not be changed without seeking the advice of the software vendor.

To set up or edit these settings:

- Click File

Setup

Setup

Installed Machines or select the Installed Machines icon from the Utility Bar.

Installed Machines or select the Installed Machines icon from the Utility Bar.

- Click the machine you wish to amend and double click it or click

.

.

- Click the Special Features tab.

Depending on the machine you have, there may be several options displayed on this tab. The illustration above shows Special Features such as Return Home At End of Sheet, Autoload After Return Home, and more.

Allow Arc as First/Last Cut: When this option is selected, it allows the program to generate NC code which uses an Arc for the first and last cut of a part, if required, instead of having to end on a straight

Allow Full Circle: When this options is selected, it allows the program to generate a Full circle instead of many small straights.

Exchange Drilling Axes in Reports: When this option is selected, for machines that are fitted with a drill, the following print objects, related to the X and Y axes values for the drill position, are swapped in a report such as a Part Report.

- Drill X Position (Part)

- Drill Y Position (Part)

- Drill X Position (Sheet)

- Drill Y Position (Sheet)

This can be useful in scenarios where the machine’s origin is actually at the top left corner, rather than the bottom left corner, and there is a need to capture this detail in a Part Report. So, for example, the X axes drill position value is swapped for the Y axes drill position value, and vice versa.