The Fill Between 2 Ends command lets you join two items of duct or pipe that are distances apart. The command prompts the selection of duct/pipe ends to be joined, then presents possible solutions for joining the items, including the totals for Weight, Area, Installations Time and Cost for each solution.

The Fill Between 2 Ends command uses the items available from the currently selected service. The items should be certified to prevent being prompted for sizes etc. If the items are not certified, you must click OK on each item's Edit dialog.

When using the fill, items are automatically sourced in the order they are displayed. If there are two bend items i.e. Radius and Mitred, the first item in the service is used. There is the option to exclude any of the service items from the fill, refer to the Exclude from Fill option.

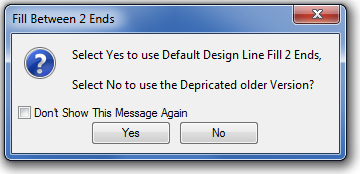

For 2.41 or later versions, the Fill Between 2 Ends button  initially prompts which method to use:

initially prompts which method to use:

Click No to use the older Fill Between 2 Ends.

Configuration

Configuration  Message Prompts, and enable the Fill Between 2 Ends Style option.

Message Prompts, and enable the Fill Between 2 Ends Style option. Other methods of launching the command are:

- At the command line, type F2E and then press Enter

- From the Shift+Right-click menu

Fill Between 2 Ends

Fill Between 2 Ends

Toolbars and Fly-out menus

Change Views

Change Views

Fly Mode

Fly Mode

Glide Mode

Glide Mode

Walk Mode

Walk Mode

Navigate Mode

Navigate Mode

Show Items

Show Items

Show UCS Axis

Show UCS Axis

Show Design Lines

Show Design Lines

Show Underlays

Show Underlays

Show Proxy Graphics

Show Proxy Graphics

Show Dimensions

Show Dimensions

Show Zones

Show Zones

Clipping Planes

Clipping Planes

List All Commands

List All Commands

Styles

Styles

Rotate View

Rotate View

Viewer In Viewer

Viewer In Viewer

Zoom To Fit

Zoom To Fit

Zoom To Selected Region

Zoom To Selected Region

Store Camera

Store Camera

Retrieve Camera

Retrieve Camera

Fill Examples

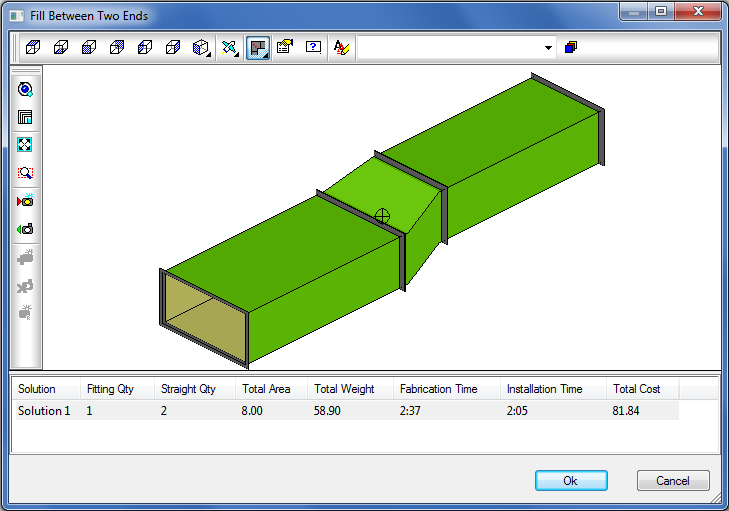

Duct/Pipe - Items positioned 90o to each other on the XY Plane, there is difference in the Z height between the connector nodes and the end sizes are the same. Other angles are supported, but this depends on the Service selected and the available products.

The number of solutions provided can be affected by the distances between the open ends, shorter distances may not allow the placement of all available fittings. E.g., if the fill routine to consider placing 60o bends rather than 90o, the distance between open ends may need to be increased.

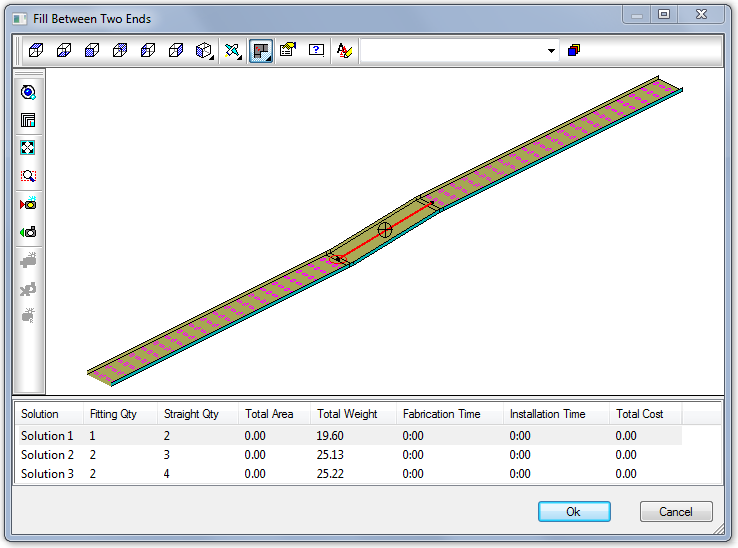

Electrical - Ends are parallel to each other on the XY Plane. There is a difference in the Z height between the connector nodes and the end sizes are the same.

Single Fittings - Ends are parallel to each other on the XY Plane: there is a difference in the Z height between the connector nodes and the duct end sizes are different: a transition is required and will be offsetting in 2 directions.