Machining undercuts

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

Accessibility Analysis highlights parts of your design that are visible from a selected plane view. Use this tool to identify undercuts and recessed surfaces in your design that may be difficult to manufacture. For example:

- Subtractive: Undercuts may be inaccessible for certain machining operations or setups.

- Casting: Undercuts can cause prevent the part from being directly ejected from an injection molding machine.

- Additive: Undercuts may need additional supports in additive manufacturing processes.

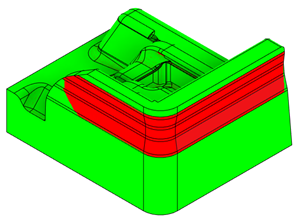

Example of an undercut area shown in red

Machining undercuts with 3-axis motion

Using the Machine Undercuts parameter, you can generate a 3-axis toolpath to machine undercut areas. Lollipop, disc, barrel, or dovetail tools are best suited for 3-axis undercut machining.

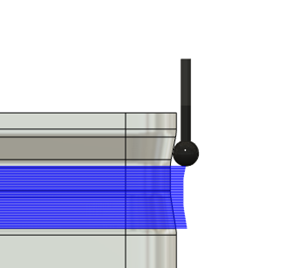

Undercut areas machined by a lollipop tool

Machining undercuts with 5-axis motion

Using the Machine Undercuts parameter and the options in the Multi-Axis tab, you can generate a 5-axis toolpath to machine undercut areas. When compared to 3-axis machining, you can use a wider range of tools during 5-axis machining, including a ball-nosed tool. Generally, using 5-axis motion when machining undercuts gives you the ability to reach more areas of a part in a single operation, which saves you valuable programming time.

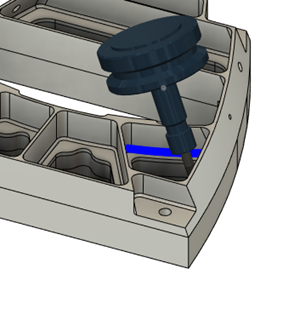

Undercut areas are machined by a ball-nosed tool