Pencil Overthickness reference

Detect pencil passes for your specified tool.

The Overthickness setting enables you to detect pencil passes for your specified tool by first calculating the passes with a thickened tool, and then projecting the specified tool between the bi-tangent points of the larger tool onto the surfaces. This makes it possible to find paths along a corner fillet where the fillet radius is slightly greater than the tool radius.

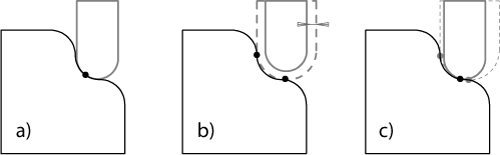

a) The ideal position of a small tool on a larger fillet only has one contact point and is not detected b) With overthickness, a larger tool is used for calculation and gives two contact points c) The resulting tool position is determined by projecting the tool onto the surface at the halfway point between the small and overthickened tool

Example: If you have a fillet with a radius of 5 mm that you want to machine with a tool with a corner radius of 4.5 mm (e.g. a 9 mm ball tool), you can set the overthickness parameter to 0.5 mm. This calculates the toolpaths as if you had been using a 10 mm ball tool, but adjusts the toolpath so it can be machined with the 9 mm tool.