Lift Height and Stay-Down Moves reference

Move the tool away from the stock during the transitions.

Some of the machining strategies in Fusion perform stay-down movements when transitioning between cutting toolpaths. These transitions are done at the same Z-level as the cutting passes. By setting Lift Height, you can move the tool away from the stock during the transitions. Lifting the tool helps to avoid witness marks and allows higher feedrates.

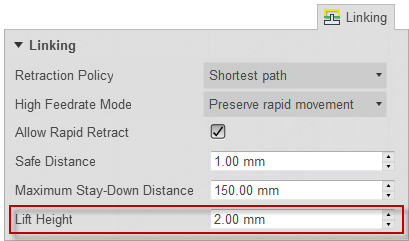

The Lift Height setting is available for the 2D and 3D Pocket, Adaptive Clearing, and Horizontal Clearing strategies on the Linking tab.

The Lift Height setting

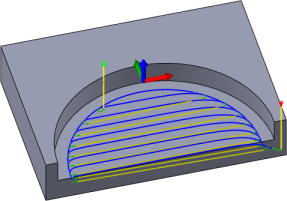

The following image shows an example of a 2D Adaptive toolpath with stay-down moves connecting each machining pass.

A 2D Adaptive toolpath with stay-down moves

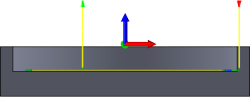

By default, these stay-down moves are done at the same Z-level as shown in the following image

Side view of the toolpath with Lift Height set to 0 mm

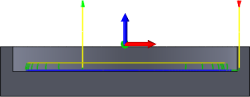

With the Lift Height set, the toolpath looks like this instead:

Side view of the toolpath with Lift Height set to 2 mm