Machining Time

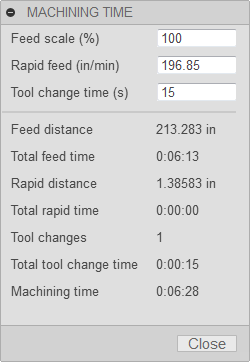

The Machining Time ![]() tool displays the estimated machining time for setups, NC programs, or individual operations. It also shows the feed distance and time, rapid distance and time, and the number of tool changes and tool-change time.

tool displays the estimated machining time for setups, NC programs, or individual operations. It also shows the feed distance and time, rapid distance and time, and the number of tool changes and tool-change time.

The Machining Time dialog

The machining time is the sum of the feed time, rapid time, and tool-change time. These values are calculated using the feeds and speeds of the tools, the distance of the calculated toolpaths, and the rapid feed rate for the machine tool.

You can evaluate how changing the feed rates for operations impacts the overall machining time. The Feed Scale lets you reduce or increase the toolpaths’ cutting, lead-in, lead-out, ramp, and plunge feedrates. Generally, reducing feed rates gives a better surface finish, but increases the overall machining time.

The Rapid Feed is the quickest the machine tool can move the tool. Consult the machine-tool manufacturer for this information.