NC program code samples reference

These are samples of the types of code changes you can make using the parameters on the Settings tab. This is not a complete list, only the more common code changes are shown.

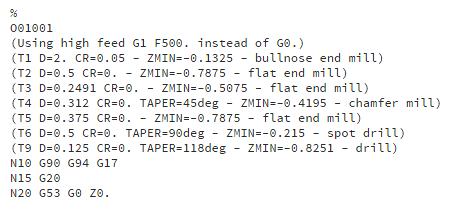

Name/number - Enter the program name or number depending in the requirements of your NC Control. In many G-Code controls this is shown as the first line of the NC program. Preceded by the letter "O".

Comment - Enter a description about the machining job. This might be a part number, customer name, or special fixturing information. This is usually displayed as a comment in the first few lines of the NC program.

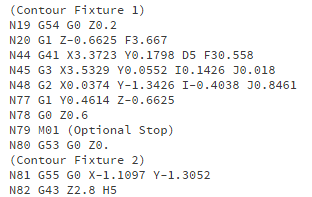

Optional stop - Outputs the machine code to stop machine motion, based on a condition set at the CNC control. Used to stop the machine between toolpath operations for part/tool inspection. Shown below on line N79.

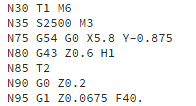

Preload tool - Also called Tool Staging, this will preposition the next tool so it will be ready for the tool change sequence. Line N30 Calls for a tool change of Tool 1 and line N85 preloads/stages Tool 2 the tool for the next operation.

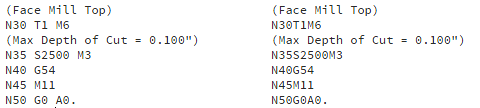

Separate words with space - Adds a space between NC code words for easier reading by the operator.

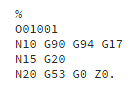

Sequence number increment - Specifies how block numbers should be incremented.

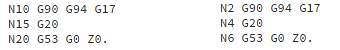

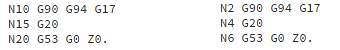

Starts at 10 and increments by 5. - Starts at 2 and increments by 2.

Start sequence number - Specifies the number for the first code block in the NC program.

Starts at 10 and increments by 5. - Starts at 2 and increments by 2.

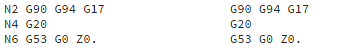

Use Sequence numbers - Specifies if block numbers should be used in the NC program.

Sequence Numbers On - Sequence Numbers Off

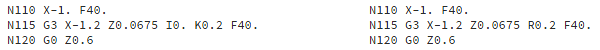

Radius arcs - Changes the format of Arcs from an IJK center definition to an Arc specified by Radius size.

Write machine - Writes machine information that is listed in the machine Postprocessor, to the NC program.

Write tool list - Creates a list of the tools in the NC Program. Can include information like Tool number, Tool Size and Tool offsets.