Post Process tab reference

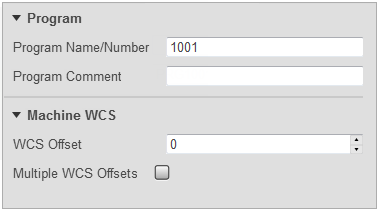

Post Process tab settings

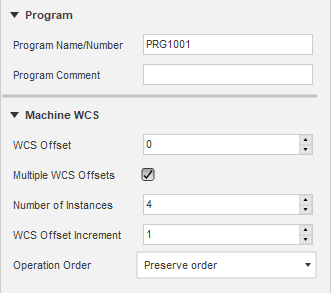

Post Process tab settings

Post processing parameters like the program name or number, program comment, and work offset can be provided on the Post Process tab

The work offset is mapped by the post processor configuration to the corresponding zero table index (for example, G54-G59) on the CNC control. A value of 1 would normally be setup to be the first available zero index on the CNC control (for example, G54). The WCS and work offset are generally setup to match one another on a one-to-one basis.

Program Name/Number

Specifies the program name or number. This parameter is made available to the post processor.

Program Comment

Specifies the program comment. This parameter is made available to the post processor.

WCS Offset

The number of the coordinate system that drives the operations in this setup. The number matches a specific G-code, which is defined by the post processor.

Multiple WCS Offsets

Enable to specify that the workpiece is to be duplicated.

Number of Instances

Specifies the number of workpiece duplicates.

WCS Offset Increment

Specifies the work offset increment used for workpiece duplication.

Operation Order

Specifies the ordering of the individual operations.

- Preserve order - Specifies that features are machined in the order in which they were selected.

- Order by operation - Specifies the ordering of the individual operations.

- Order by tool - Specifies the ordering of operations by tool. For example, all operations that use a Ø3/4" flat mill are machined first. Then the next set of operations that use another identical tool, a Ø1/4" flat mill for example, are machined next.

Using Multiple Setup Work Offsets

Fusion supports patterning of entire setups using the Multiple WCS offsets feature, which essentially duplicates entire setups using different work offsets. This feature is generally used when the individual position of each instance is not precisely known.

Once you enable Multiple WCS offsets, you can specify the total number of instances and the work offset increment to be used. You can also choose the order of the duplicated toolpath (by setup, by operation, or by tool).

Enabling multiple work offsets

The setting for the WCS Offset field depends on the post processor. In this case we are using a Fanuc post, so specifying 1 will use the first work offset (G54). The next field is the number of duplications, in this case 4, so each of the next offsets is incremented by 1 and will then be G55, G56 and G57.

If the physical setups of each instance are evenly spaced, it is sometimes possible to use a normal pattern feature instead. This allows you to fully simulate the duplicated toolpath. However, this approach requires you to add toolpaths to align the stock for each instance.