Modify leads and links

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

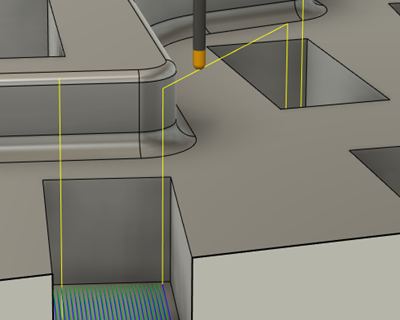

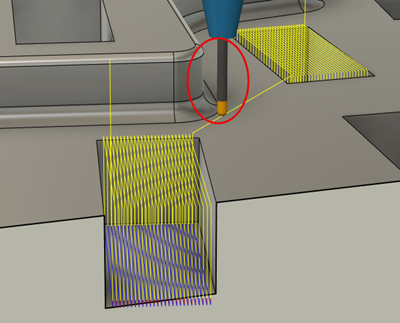

In the example below, the toolpath is programmed such that there is a retract move for each pass inside the pockets. Secondly, the linking move between the two pockets is set to a minimum retraction, which keeps the tool as low as possible. As a result, the tool is quite close to the wall that is between the two pockets.

In this scenario, you may want to increase the Maximum Stay-down Distance so that the tool stays down between each pass inside the pocket. You may also want to increase the Radial Safe Distance for safer clearances between the tool and the nearby wall as it moves from one pocket to another.

In the Manufacture workspace, select the toolpath that you want to modify.

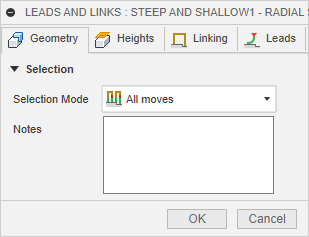

From the toolbar, in the Modify group, select Leads and Links. The Leads and Links dialog opens.

On the Geometry tab, from the Selection Mode drop-down menu, select All moves to modify all the leads and links in the toolpath.

(Optional) On the Heights tab, adjust the Clearance Geometry if needed.

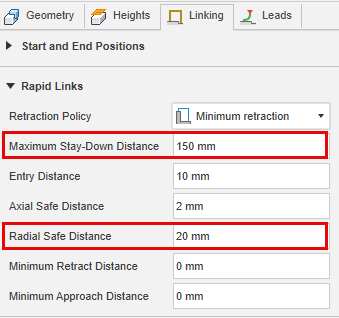

On the Linking tab, in the Rapid Links group, increase the Maximum Stay-Down Distance. This will keep the tool down between each pass inside the pocket.

Increase the Radial Safe Distance for more clearance between the tool and the wall. This will lift the tool further up until it is able to maintain the radial safe distance.

On the Leads tab, verify that the default lead settings are appropriate for your toolpath.

Click OK to modify the toolpath.

The modified toolpath no longer has large retracts between each pass, and the tool maintains a safe distance from the wall as it moves between the two pockets.