Sheet metal rule reference

In the Design workspace, on the Sheet Metal tab, the edit rule and new rule dialog allow for customizing specific sheet metal features.

Design > Sheet Metal > Modify > Sheet Metal Rules ![]() > New Rule

> New Rule ![]()

Design > Sheet Metal > Modify > Sheet Metal Rules ![]() > Edit Rule

> Edit Rule ![]()

Thickness

Specifies the thickness of the material.

K-factor

When sheet metal is bent, the external surface stretches while the internal surface compresses. The neutral axis shifts towards the inside of the bend. K-factor is the ratio of the neutral axis offset from the internal bend surface to the material thickness.

Gap value

Specifies the value of the space between a flange miter, rip, or seam gap.

Bend conditions

Bend conditions include the bend radius and the relief shape, width, depth, and remnant dimensions.

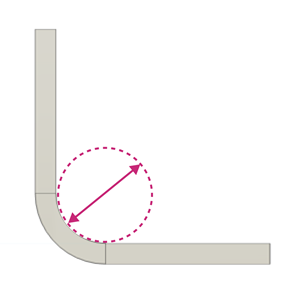

Bend Radius: Specifies a distance from the inner surface of the sheet to the center of the bend. This controls how tightly the material bends and affects both strength and appearance.

Relief Shape: Specifies the shape of the relief at the corner of a bend. These images preview the bend reliefs in both folded sheet metal design and flat pattern.

Round: Creates a rounded notch bend relief with the width, depth, and remnant that you specify.

Straight: Creates a squared notch bend relief with the width, depth, and remnant that you specify.

Tear: Creates no bend relief, so the material is torn at the corner with remnant that you specify.

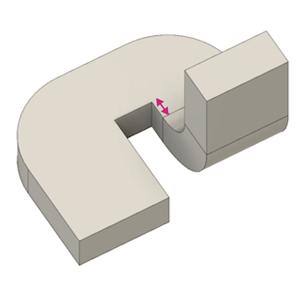

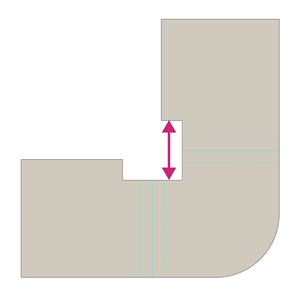

Relief Width: Specifies the width of the bend relief.

Relief Depth: Specifies the depth of the bend relief.

Relief Remnant: Specifies the depth of the bend relief.

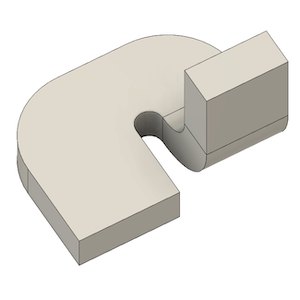

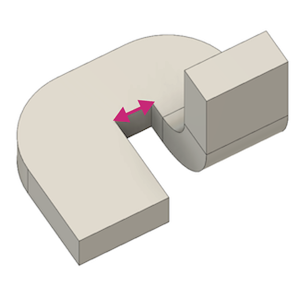

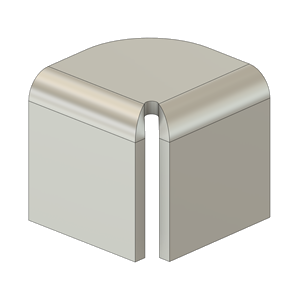

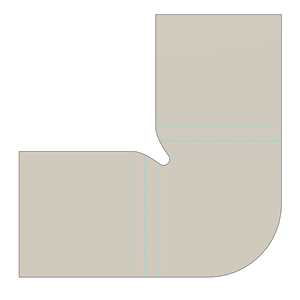

2 Bend corner relief type and size

Specifies the relief shape, size, and placement at corners where two bends intersect.

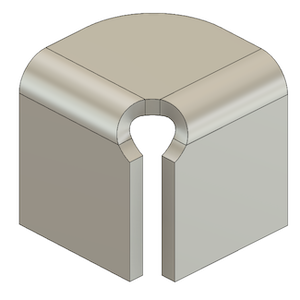

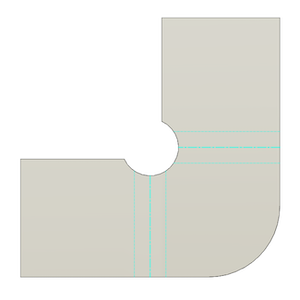

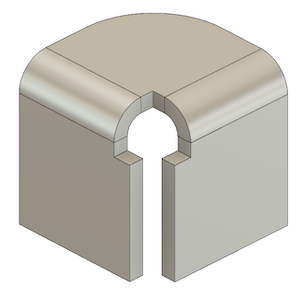

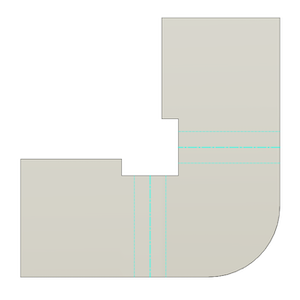

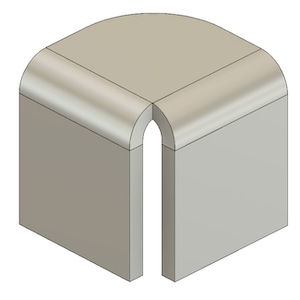

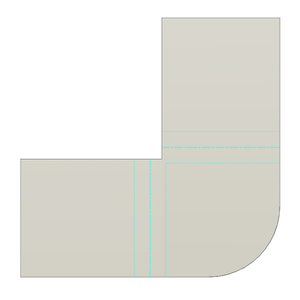

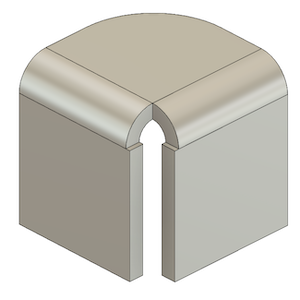

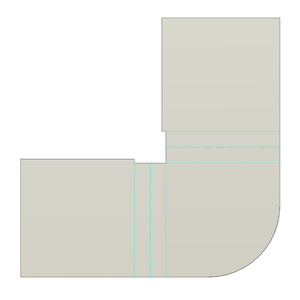

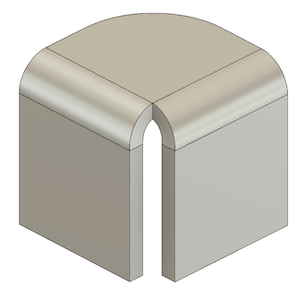

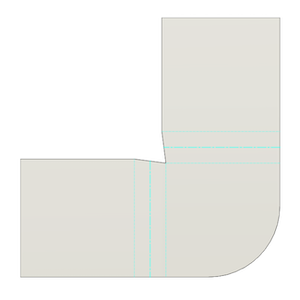

Relief Shape: Specifies the shape of a two bend corner relief. You can see images of various corner relief shapes below. These images preview the bend reliefs in both folded sheet metal design and flat pattern.

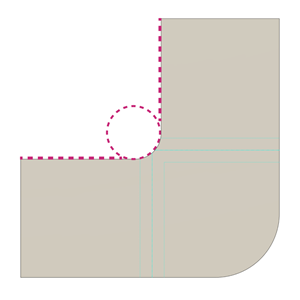

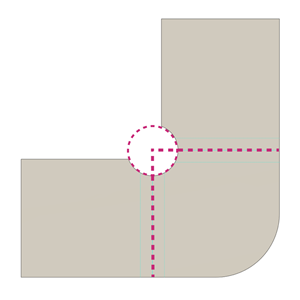

Round: Creates a circular bend relief centered on the corner where two bends meet. You specify the size and placement of the relief.

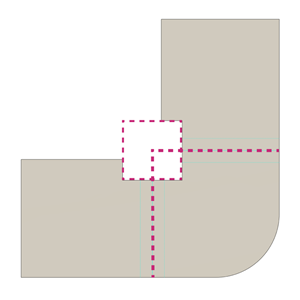

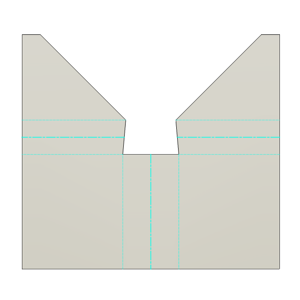

Square: Creates a square bend relief centered on the corner where two bends meet. You specify the size of the relief.

Tear: Creates no bend relief, so the material is torn at the corner where two bends meet.

Trim To Bend: Creates a square bend relief centered on the corner where two bends meet. The square size is determined by the bending area.

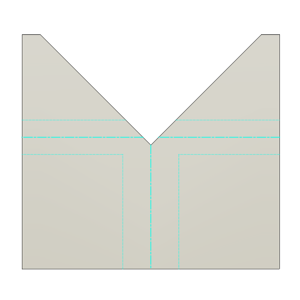

Linear Weld: Creates a V-shaped bend relief. The V size is determined by the bending area.

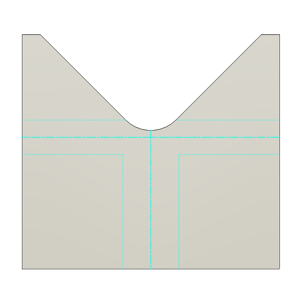

Arc Weld: Creates a blunt notch bend relief with spline edges limited by the bending area.

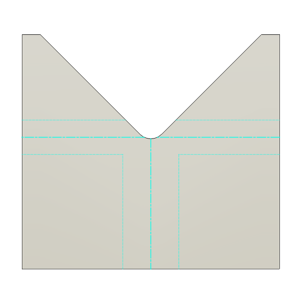

Laser Weld: Creates a circular notch bend relief with spline edges limited by the bending area.

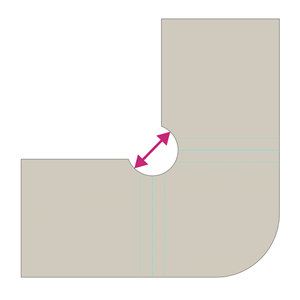

Relief Size: Specify the relief size value of a corner where two bends intersect. This dimension is measured when the sheet metal body is unfolded. Available for Round and Square relief shapes.

Relief Placement: Specify the location of a relief shape at corners where two bends intersect.

Tangent: Places a rounded relief shape so that it is tangent to the edges of two flanges where they meet the base flange. Available for Round relief shape.

Intersection: Centers the relief shape on the intersection where two flanges meet the base flange. Available for Round and Square relief shapes.

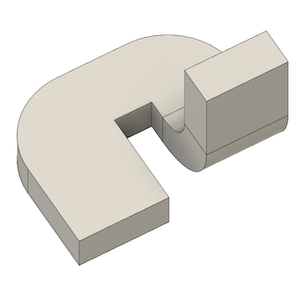

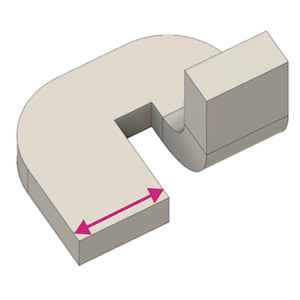

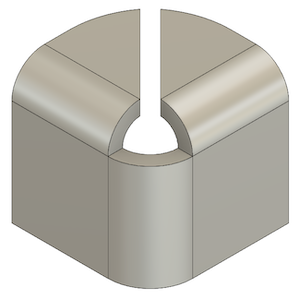

3 Bend corner relief type and size

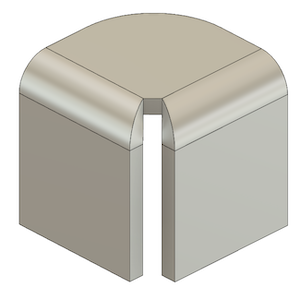

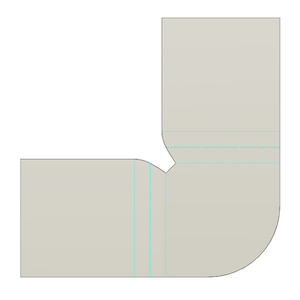

Specifies the relief shape and radius at corners where three bends intersect. The three bend corner relief shape will only be visible in flat pattern view.

Relief Shape

No Replacement: Creates no special bend relief shape at the corner where three bends meet.

Intersection: Creates a bend relief shape by extending the flange edges until they intersect.

Full Round: Creates a bend relief shape by extending the flange edges until they intersect, then adding a full round fillet at the intersection, tangent to the flange edges starting at the bend zone.

Round With Radius: Creates a bend relief shape by extending the flange edges until they intersect, then adding a fillet of a size that you specify to round the intersection.

Relief Radius: Specify the relief radius value to override the sheet metal rule.