Filled from injection location result

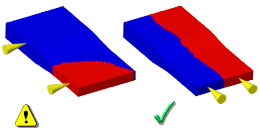

The Filled from injection location result shows the areas of the cavity that are filled from each injection location, when multiple injection locations are used, so you can determine whether the flow is balanced.

Things to look for

A result that shows an equal distribution of colors will have a uniform filling pattern and be balanced, as shown in the image above on the right. If the distribution of colors is not equal, then the flow is unbalanced, as shown in the image above on the left. Check the Weld lines result to see the location of weld lines that arise when flow fronts meet.

Using this result

The Filled from injection location result uses numbers to identify the gate through which the polymer was injected. When the Filling and Packing and Cooling phases are complete, the Filled from injection location result indicates the filling pattern of the part and shows which areas of the part were filled from which gate.

Next steps

To balance the flow patterns:

- Change the injection locations if polymer is filling more quickly from one gate.

- Use the Simplify environment to modify the the geometry of the Simulation model in the problematic area.

To move weld lines that are in sensitive areas:

- Alter the gate locations

- Change the part thickness

- Increase the melt and mold temperature

- Increase the injection speed.