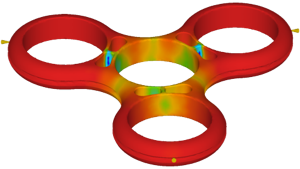

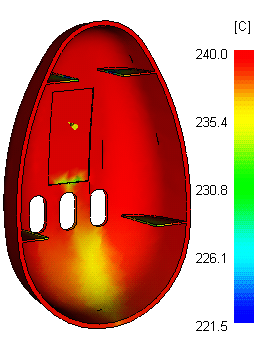

Flow front temperature result

The Flow-front temperature result shows how the temperature of the melt changes at the flow front, as the plastic fills the cavity.

Things to look for

When viewing the Flow front temperature result, watch for the following:

- Hot spots; usually these exist around the gate and in areas where excessive shear heating occurs.

- Cold spots indicating hesitation.

- Check whether the material is cooling excessively.

Using this result

The Flow front temperature result uses a range of colors to indicate the region of lowest temperature in blue through to the region of highest temperature in red. The colors represent the melt temperature at each point in the cavity, as that point was filled.

The flow front temperature should not drop more than 2°C to 5°C during the filling phase. Smaller temperature variations result in fewer molding problems. Larger changes often indicate that the injection time is too low, or there are areas of hesitation. If the flow front temperature is too low in a thin area of the part, hesitation may result in a short shot. In areas where the flow front temperature increases by several degrees, material degradation and surface defects may occur.

Next steps

The following methods can be used to prevent air traps:

If the temperature is too low:

- Decrease the injection time - this may cause material degradation if it is too short

- Increase the melt temperature - but keep it within the temperature limits specified by the material manufacturer

- Increase the mold temperature - this may increase the cycle time

- Modify the model - increase the thickness in the area bearing in mind the function of the part.

If the temperature is too high:

- Increase the injection time - but this may cause hesitation.