Injection locations

The Injection Locations ![]() command enables you to define the locations where the polymer is injected into the part. This enables simulate the flow pattern inside the mold cavity.

command enables you to define the locations where the polymer is injected into the part. This enables simulate the flow pattern inside the mold cavity.

To mold the best part possible, you must identify the optimal injection locations. This will create a balanced filling pattern by allowing the extremities of the mold to fill at the same time and under the same pressure. You must also select the number of injection locations required and their positions so that the volumetric shrinkage at the end of the flow is close to the design value.

Place an injection location on the body that minimizes the distance the polymer must flow. Ideally, inject into a thicker section, and aim for balanced filling. For larger parts, you may add multiple locations.

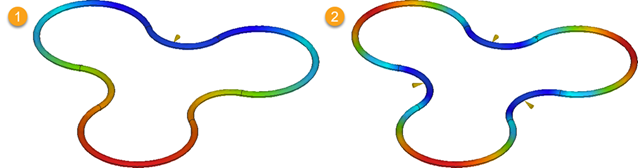

Fill animation results: (1) One location; (2) Multiple locations.

Avoid faces that should be free from blemishes. Faces you have identified as aesthetic faces are highlighted in green to help you avoid them.