Injection time

The time it should take to completely fill the mold with material.

The effect of the variation of injection pressure against injection time is two-fold:

As the injection time increases from zero, the pressure to force the molten plastic through the part decreases.

As the injection time increases, the plastic temperature decreases due to heat transfer to the mold. It causes the viscosity and the amount of solidified plastic to increase, which in turn increases the injection pressure.

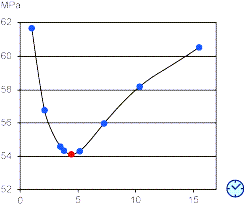

You can set the injection time to Automatic or Specified. The following graph shows the results from nine simulations for the same part.

Blue points represent the simulations where the injection time was set to a particular value.

The red point represents the analysis where the Automatic injection time was selected. It shows the lowest possible injection pressure for the part.

The graph showing the results from nine simulations for the same part.