Quality prediction result

The Quality Prediction result is used to estimate the quality of the mechanical properties and appearance of the part. This result is derived from the pressure, temperature, and other results.

Fill confidence

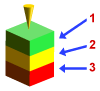

The colors displayed in the Quality prediction result indicate the following:

- Will have high quality

- May have quality problems

- Will definitely have quality problems.

Things to look for

Colors other than green indicate that you may have problems with the quality of molded part. Note the location of these other colors - if yellow\orange areas occur where mechanical strength in not needed, or where the quality of the surface appearance is unimportant, they may be of no concern. As the percentages of yellow/orange and red increase, the part quality decreases.

Using this result

A good quality part is defined by whether or not it meets the design specifications for mechanical strength and surface appearance. When analyzing this result to determine whether a good quality part can be molded, consider which colors are visible and how much of each color appears. You should also look at the Fill Confidence result to see how likely it is that the part will fill.

If the part is mostly green, with some small yellow/orange areas, it may be acceptable but you should look carefully at other results to see where and why the area is not green.

If there are yellow/orange or red areas, it may be that the temperature in those areas was too low, or too high, as the plastic flowed through them. The temperature at the flow front is one factor used to determine the confidence that the cavity will fill.

Problems caused by temperature:

- The temperature at the flow front is too low.

- If this occurs in a thin area of the part, hesitation or a short shot may occur.

- If this occurs in an area where weld lines are present, the weld lines may appear worse and the part may be structurally weaker.

- The temperature at the flow front is too high.

- This can cause material degradation and surface defects. Ensure that the temperature at the flow front is always within the recommended range for the polymer you are using.

Next steps

There are a number of ways to improve the quality prediction result, but it is important to remember that as you make changes, there will be other consequences. To improve the quality prediction result when temperature is the cause of problem areas:

- Increase the melt or mold temperature - but this may cause material degradation and increase the cycle time. Keep the temperature within the material's recommended limits.

- Alter the part thickness - but this may cause functional problems with the design. Low melt temperature can be caused by hesitation. To avoid hesitation, increase the thickness of problem areas.

- Decrease the draft angle in thin ribs where hesitation occurs - but this may cause a functional problem with the design, and may make ejecting the part more difficult.

- Change the injection location - move the injection location closer to the problem area, or add additional injection points. This will increase the likelihood of all sections of the cavity filling and being of acceptable quality.

- Move the injection location away from the hesitation area - but this may cause hesitation or other problems elsewhere in the part.

- Alter the processing conditions of the selected material - to improve the quality prediction, increase the melt temperature of the current material.

- Select a different material - select a material with a higher melt flow (lower viscosity).

- Decrease the injection time - but this may cause material degradation and surface defects.