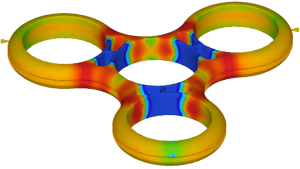

Time to ejection temperature result

The Time to ejection temperature result shows the time required to reach the ejection temperature, measured from the start of fill.

Things to look for

When viewing the Time to ejection temperature result, watch for the following:

- Is the part sufficiently frozen at the end of the packing and cooling phase?

- Is the injection location, or gate, freezing off too early before the cavity can be adequately packed out?

- Are there thinner regions freezing off before more extreme thicker regions, thereby preventing the thicker regions from being adequately packed out?

Using this result

Ideally, the part should freeze uniformly. Areas of the part that take longer to freeze may indicate thicker areas of the part.

Check that there are no regions that of the part that are taking much longer to reach the ejection temperature much than the upstream areas closer to the injection location. Those late cooling areas will not be well packed and may have significant sink mark defects or cause large warpage.

If it takes a long time to reach the ejection temperature because of thick areas in the part, consider redesigning the part. If the time to reach ejection temperature for the part as a whole appears high, you may need to reduce the cycle time by reducing the mold and the melt temperatures.

Next steps

The following options can be used to solve problems with excessive time to reach ejection temperature:

- Consider redesigning the part, to reduce the relative thicknesses of the design.

- Move the injection locations closer to the thicker areas of the part.

- Reduce the mold and melt temperatures so that the plastic freezes faster.