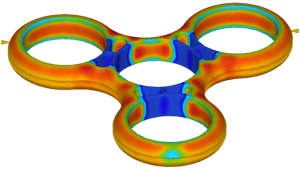

Volumetric shrinkage (ejection) result

The Volumetric shrinkage (ejection) result shows the decrease in local volume from the end of the cooling stage to when the part has cooled to the ambient reference temperature (the default value is 25°C/77°F).

Things to look for

When viewing the Volumetric shrinkage (ejection) result, watch for the following:

Localized areas of high shrinkage can result in internal voids or sink marks when the part cools

Ideally, shrinkage values should be uniform throughout the part. This is important for good packing of the material, ensuring good structural and visual integrity of the part.

A wide variation in volumetric shrinkage throughout the part can result in increased warpage.

Negative volumetric values indicate expansion rather than shrinkage. Avoid negative shrinkage on ribs because this can cause ejection problems

Check that values are in the expected range for the material.

Using this result

The Volumetric shrinkage (ejection) result shows the volumetric shrinkage for each area, expressed as a percentage of the original modeled volume. This result can be used to detect sink marks on your model. High shrinkage values could indicate sink marks or voids inside the part.

Minimize the variation in volumetric shrinkage throughout the cavity to minimize warpage.

Next steps

The following options can be used to solve problems with excessive or non-uniform volumetric shrinkage:

- Select a material from the database with a lower average nominal shrinkage. Materials that are gold rated for warpage have more complete material properties data.

- Modify the model design to minimize the variation thicknesses throughout the part.