About Line Balancing

Balance your production line to ensure your production rate meets the customer demand.

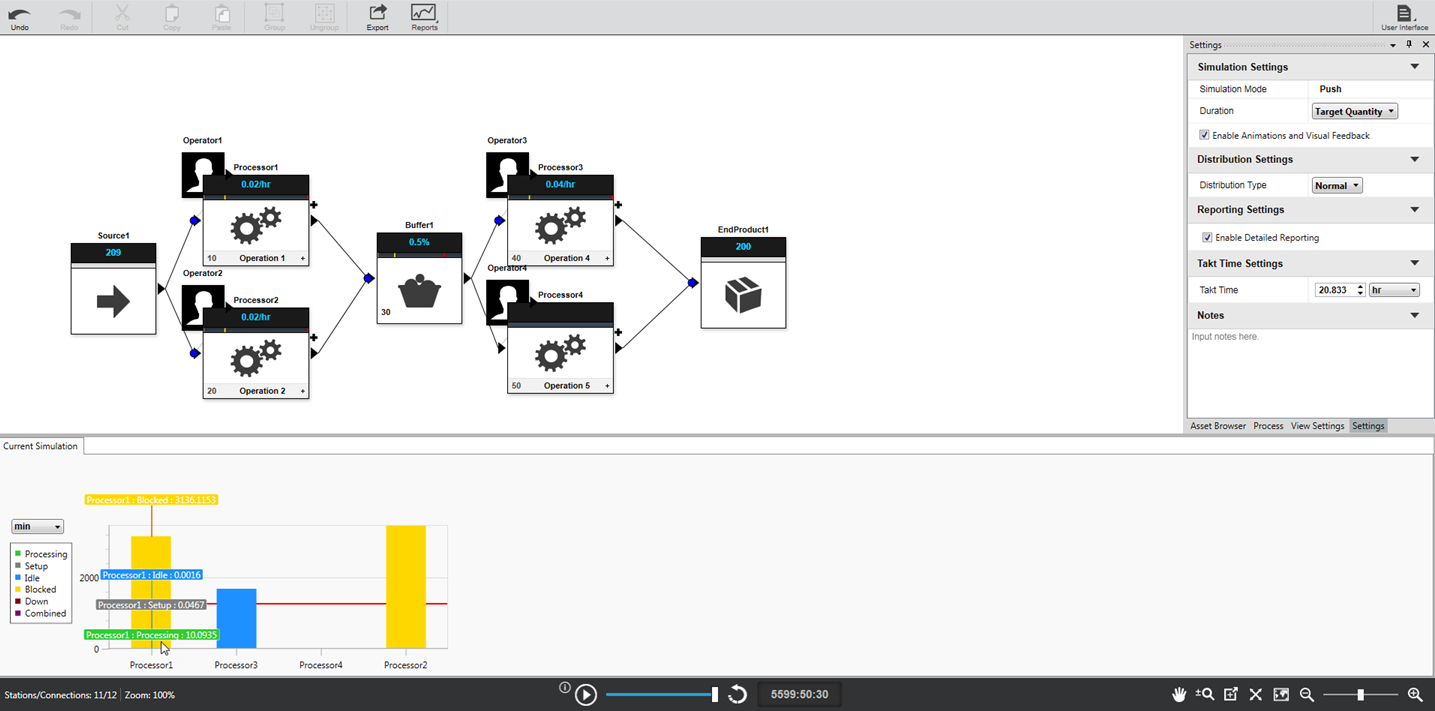

In Process Analysis, you can balance your manufacturing process' production rate to ensure that your production line runs smoothly to meet the production schedule. When the balance is off in your manufacturing process, resources are not functioning at their most optimal speed resulting in wasted time and slower throughput. Line balancing allows you to make sure the tasks at each step fo the manufacturing process take the same amount of time as closely as possibly to increase productivity on the production line.

Line Balancing

Line Balancing is spreading out a workload across all processes to eliminate bottlenecks on the factory floor and optimize the manufacturing process.

Process Analysis supports single-model and single-product line balancing.

Takt Time

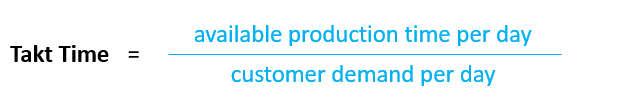

To calculate takt time, you first need to understand the customer demand, or production target production schedule. Takt Time is the maximum amount of time in which a product needs to be produced to satisfy customer demand. Takt time is the cadence, or rhythm, at which your production line processes a part or produces an item to fulfill the customer demand. A takt time calculation allows you to better understand your process and adjust the total workflow and the division of labor among multiple workstations.

For example, if a factory operates 1,000 minutes per day and the customer demand is 500 widgets per day, then the takt time is 1,000 / 500 = 2 minutes.

The time available for a production period should account for the total number of time employees spend working in production, subtracting the time employees spend on breaks, meetings, or other time spent away from production. The takt time settings are based on a 24-hour day and does not account for down time due to mechanical problems in machinery.