Issue:

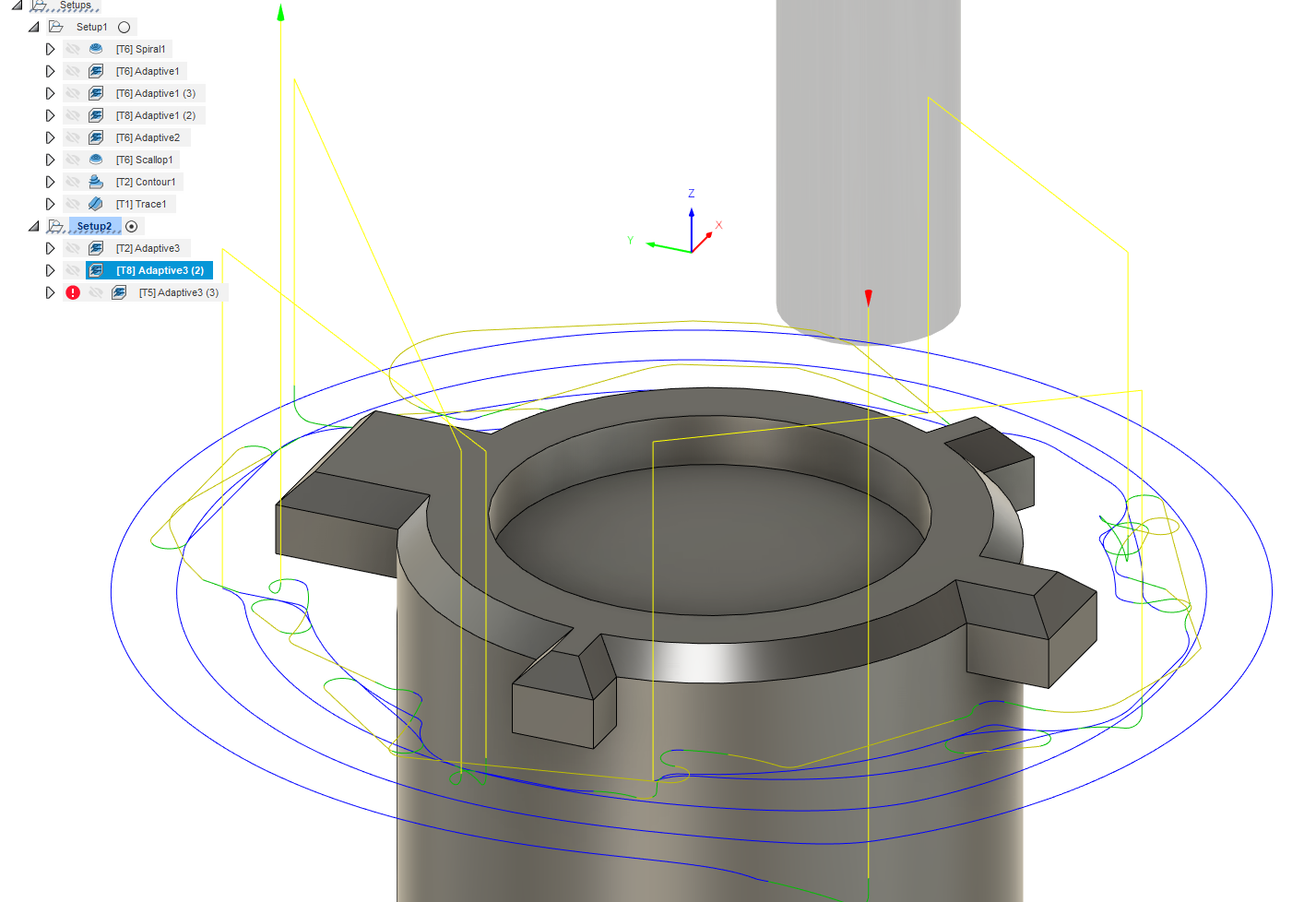

A 3D adaptive toolpath is not machining an pocket or hole in Fusion Manufacture:

Causes:

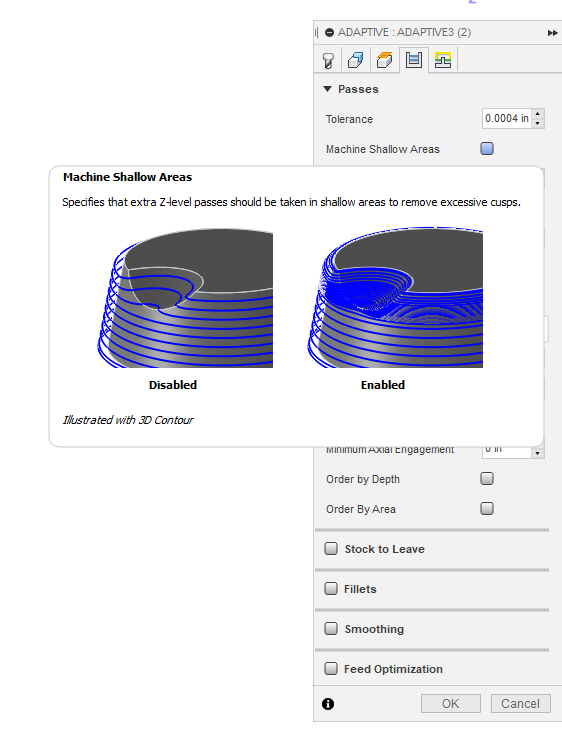

- The 3D Adaptive isn't set to 'machine shallow areas'. This is a combination of tool size, pocket depth and lead constraints.

- The given ramping parameters do not allow the tool to enter the pocket due to XY-plane space constraints.

Solution:

- Enable Machine Shallow areas if shallow areas are not being machined.

- Ensure the ramping parameters allow the tool to enter the pocket. Consider stock to leave, tool size, pocket size, minimum cutting radius, etc. A good way to isolate if the ramping constraints are the cause of this problem is to set the operation to use predrill or plunge entry and see if the pocket is machined. If so, the ramping diameter for a helical entry is likely too large to enter the problematic pocket.