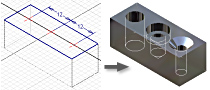

Define holes, and create them automatically.

In the part and assembly environment, you can create counterbore, countersink, spotface, and drilled holes with custom thread and drill point types. You can specify a simple hole, a tapped hole, a taper tapped hole, or a clearance hole and include thread types from the thread data sheet.

You can set tolerances for hole dimensions in the Holes dialog box. In the hole preview area, right-click a dimension edit box, and then select Tolerance.

In the assembly environment, you can use Bolted Connection Generator to create holes. On the Design tab, Fasten panel, click Bolted Connection.

You can create holes individually, or in a pattern, using the Circular Pattern or Rectangular Pattern commands to set spacing and arrangement.

Hole features in multibody part

In a multibody part environment, choose the solid bodies to participate in the hole feature. For example, in a part file with two or more solid bodies, select one or more of them to participate in a through all hole.

Strategies for creating multiple holes

For part features, a single hole feature can represent multiple holes with identical configurations (diameters and termination methods). You can create different holes from the same shared hole-pattern sketch.

In the part environment, create multiple holes as a single feature using either sketched hole centers or selected endpoints or center points of geometry. You can change dimensions, hole type, termination, and other parameters for all holes at once.

Create a single hole and duplicate it in a pattern. Define the count and spacing of the holes in the pattern. For holes in a pattern, as well as the hole characteristics, edit both the hole feature and the pattern feature.

In the part environment, use a shared sketch to create a pattern with multiple hole features and more than one hole size or type. Shared sketches are not available when creating the hole as an assembly feature.

Clearance holes for standard fasteners

Clearance Holes are standard, untapped (and usually through) holes that are toleranced to fit specific fasteners. Use them to create clearance holes for standard fasteners based on a library of standard fastener data.

Fastener information can be included in hole notes in drawings.

To manage clearance data, the program uses the Clearance.xls Microsoft Excel spreadsheet file, which is located in the Design Data folder. The Application Options or project settings affect the location of the spreadsheet file. You can change the order in the file so that the clearance you use most frequently is presented first. Edit the clearance spreadsheet and change the sort order number (from 1 to n) in cell B1 of each sheet to match your priority. To activate the new sort order, restart the program.

Tapped hole and taper tapped hole features

Specify tapped holes and taper tapped holes in either English or Metric standard sizes. For part hole features you can select a common thread size from a list, and its diameter is calculated.

For taper tapped holes, you specify the thread type and size and either right-hand or left-hand direction. The program calculates the diameter, taper angle, and thread depth.

To set the Major, Minor, Pitch, or Tap Drill diameter for tapped holes and taper tapped holes, use the Document Settings dialog box, Modeling tab, Tapped Hole Diameter option. Keep the default value for this option, because the thread representation in drawings is generated correctly only when Tapped Hole Diameter is set to Minor.