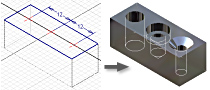

Creates parametric drilled, counterbore, spotface, or countersink hole features.

For part features, a single hole feature can represent multiple holes with identical configurations (diameters and termination methods). You can share a hole-pattern sketch to create different holes.

Access

Ribbon:

3D Model tab

Modify panel

Modify panel

Hole

Hole

![]()

Placement

- From Sketch

-

Requires a hole center point, or sketch point sketched on an existing feature. You can select endpoints, or center points on existing geometry as hole centers. Or, drag with left mouse button to select an area, and sketch points within it can serve as centers of holes.

Centers Click to select endpoints, or center points of geometry as hole centers. Selects hole center points automatically.

- Linear

-

Creates holes on a face relative to two linear edges.

Face selects a planar face to place the hole.

Reference1 Selects the first linear edge referenced for dimensioning the placement of the hole.

Reference2 selects the second linear edge referenced for dimensioning the placement of the hole.

- Concentric

-

Creates holes on a plane, concentric with a circular edge or cylindrical face.

Plane Selects a planar face or work plane to place the hole.

Concentric Reference Selects the object referenced for the placement of the hole center. Choose a circular edge, or cylindrical face.

- On Point

-

Creates holes which are coincident with a work point, and positioned relative to an axis, edge, or work plane.

Point Selects a work point to set as the hole center.

Direction Specifies the direction of the hole axis. Choose either:- a planar face, or work plane that is perpendicular to the axis of the hole,

or

- an edge, or axis that is parallel to the axis of the hole.

Flip Reverses direction of the hole.

- a planar face, or work plane that is perpendicular to the axis of the hole,

- Centers

-

Selects the location for the center of the holes.

- Solids

-

In a multibody part, selects the participating solids. Not available in a single body part.

Drilled, Counterbore, Spotface, Countersink Hole

Dimensions for the selected hole type preview dynamically on the hole. On the drop-down list, select a value. You can use Measure, Show Dimensions, or set tolerances in the Tolerance Dialog box. The values display in the parameter box on the preview image.

Drilled

Drilled -

Holes have a specified diameter, and are flush with the planar face.

Counterbore

Counterbore -

Holes have a specified diameter, counterbore diameter, and counterbore depth.

Note: You cannot use Taper Tapped Hole with Counterbore.  Spotface

Spotface -

Holes have a specified diameter, spotface diameter, and spotface depth. Measurement of the hole and thread depth starts from the bottom surface of the spotface.

Countersink

Countersink -

Holes have a specified diameter, countersink diameter, and countersink depth.

Drill Point

Sets Flat or Angle point for drill points. For angled points, on the drop-down list, specify angle dimension, or on the model, select geometry to measure a custom angle, or show dimensions. The positive direction of the angle is measured counterclockwise from the hole axis, normal to the planar face.

Termination

Specifies a termination type:

- Distance

-

Defines the termination method for the hole. Uses a positive value for the hole depth. Measures depth as perpendicular from the planar face or workplane.

- Through All

-

Extends a hole through all faces.

- To

-

Terminates a hole at the specified planar face. Select the surface on which to end the hole termination. You can terminate the feature on the extended face.

Specifies more information for hole termination:

Flip

Flip -

Reverses direction of the hole. Available when using Distance and Through All termination options.

Surface

Surface -

Terminates the hole on a selected surface or face. Available when using the To termination option.

Extended Face

Extended Face -

Specifies an extended face for the hole termination. Available when using the To termination option. Extends the face when the termination entity does not intersect completely with the hole feature.

Hole Type

Simple Hole

Simple Hole -

Creates a simple hole without thread.

Clearance Hole

Clearance Hole -

Creates a hole which fits to a selected fastener.

Standard Selects the standard for the fastener from a list.

Fastener Type Selects the type of the fastener from a list.

Size Selects the size of the fastener.

Fit Specifies whether the type of the hole fit is Normal, Close, or Loose.

Tapped Hole

Tapped Hole -

Creates a hole with a thread you define with the following options:

Thread type On the drop-down list, select a thread type. ANSI Unified Screw Thread is an example of an inch-based thread type. ANSI Metric M Profile is an example of a millimeter-based thread type.

Size Depending on the thread type selected, a list of nominal sizes displays. Each nominal size has one or more pitches available. Each nominal size and pitch combination has one or more classes available.

Designation Defines the distance from a point on a screw thread to a corresponding point on the next thread measured parallel to the axis.Note: If you use English units, the pitch is equal to 1 divided by the number of threads per inch.Class On the drop-down list, select the class of fit for the internal thread.Note: For English threads, the letter A represents external threads, and B represents internal threads. Use higher numbers for more accurate, closer fitting requirements. For instance, use 2B for screws, bolts, nuts, and other general applications. Use 3B for highly accurate and close-fitting requirements.Diameter Displays the value for the diameter type of this hole feature. You can change this value only in Document Settings. The hole diameter sets automatically from the thread specification in the Thread.xls, based on the setting (Minor, Pitch, Major, Tap Drill) in Document Settings.

Direction Specifies the direction the threads wind.

Right Hand When viewed from the end, the threads wind in a clockwise and receding direction. A right-hand threaded bolt advances into the nut when turned clockwise.

Left Hand When viewed from the end, the threads wind in a counter clockwise and receding direction. A left-hand threaded bolt advances into the nut when turned counter clockwise.

Full Depth Specifies threads the full depth of the hole.

Taper Tapped Hole

Taper Tapped Hole -

Creates a hole with a taper thread you define with following options:

Thread type I the drop-down list, select a thread type. NPT is an example of an inch-based thread type. ISO Taper Internal is an example of a millimeter-based thread type.

Size Depending on the thread type selected, a list of nominal pipe sizes, or the thread designations display.

Designation The size and thread type determine this value.

Diameter Displays the value for diameter type of this hole feature. You can change the value only in the Document Settings.

Direction Specifies the direction the threads wind.

Right Hand When viewed from the end, the threads wind in a clockwise and receding direction. A right-hand threaded bolt advances into the nut when turned clockwise.

Left Hand When viewed from the end, the threads wind in a counter clockwise and receding direction. A left-hand threaded bolt advances into the nut when turned counter clockwise.

Note: You cannot use Taper Tapped Hole with Counterbore.  Infer iMate

Infer iMate -

When selected, places an iMate automatically on a full circular edge. The selection is the closed loop most likely to be useful. In most cases, place only one or two iMates per part.