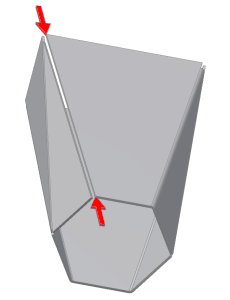

Use the Rip command to create a gap in a sheet metal part created using closed profile sketches to allow flattening. The Face Extents Rip Type requires selection of a model face that is removed to define the Rip.

- On the ribbon, click

Sheet Metal tab

Modify panel

Modify panel

Rip

.

Rip

. - On the Rip dialog box, select Face Extents from the Rip Type drop-down.

- In the graphics window, select the face of the sheet metal model to be removed as the Rip feature.

- Click OK to create the Rip and close the dialog box. Optionally, click Apply to create the Rip and leave the dialog box open to create additional Rip features.

Note: Click Cancel at anytime to discard any input and close the dialog box.

Tip: Face Extents Rip features are often used to remove a small bend face created as the result of a Lofted Flange created using Press Brake output. While removing bend faces is common, any face can be removed to create a Rip using the Face Extents option.