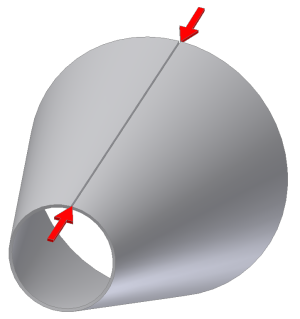

Some sheet metal designs (for example, transitional shapes created with Lofted Flange) are easier to create using closed profiles. These designs require an open gap or “rip” to allow unfolding or unrolling into a flat pattern. While a Cut feature can also create such a gap, the Rip feature is characterized by edges normal to the cut surface. Additionally, there are several options available that simplify feature creation. Create Rips by:

- Selecting a point on the edge of a surface. The selected point may be a midpoint on an edge, an endpoint on a face vertex, a work point, or a sketched point from a previously created sketch.

- Ripping between two points on opposite sides of a selected face. The two points may be work points, midpoints on face edges or endpoints on face vertices, sketch points from a previously created sketch.

- Removing an entire selected face (typically a bend face).

A Rip feature can be placed anywhere within the feature history and multiple Rip features can be placed within a single sheet metal model.

Note: Rip features do not rip across holes, cut-outs, embosses or other formed features that lie in the rip path.